Spraying equipment before coating of mechanical arm parts

A technology of spraying equipment and manipulators, which is applied to the device, coating, spraying device and other directions for coating liquid on the surface, can solve the problem of incomplete spraying, etc., and achieve the effect of increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

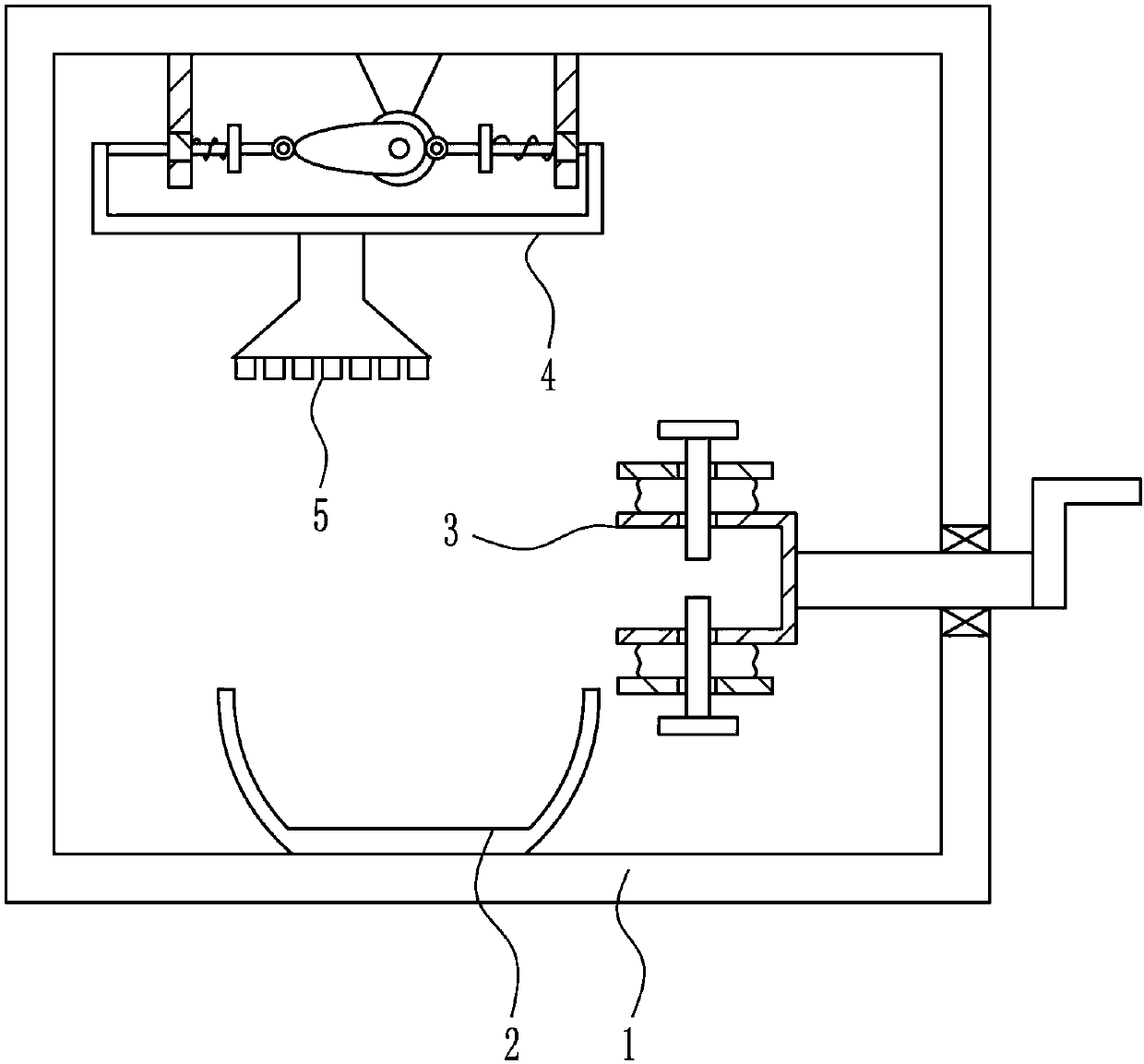

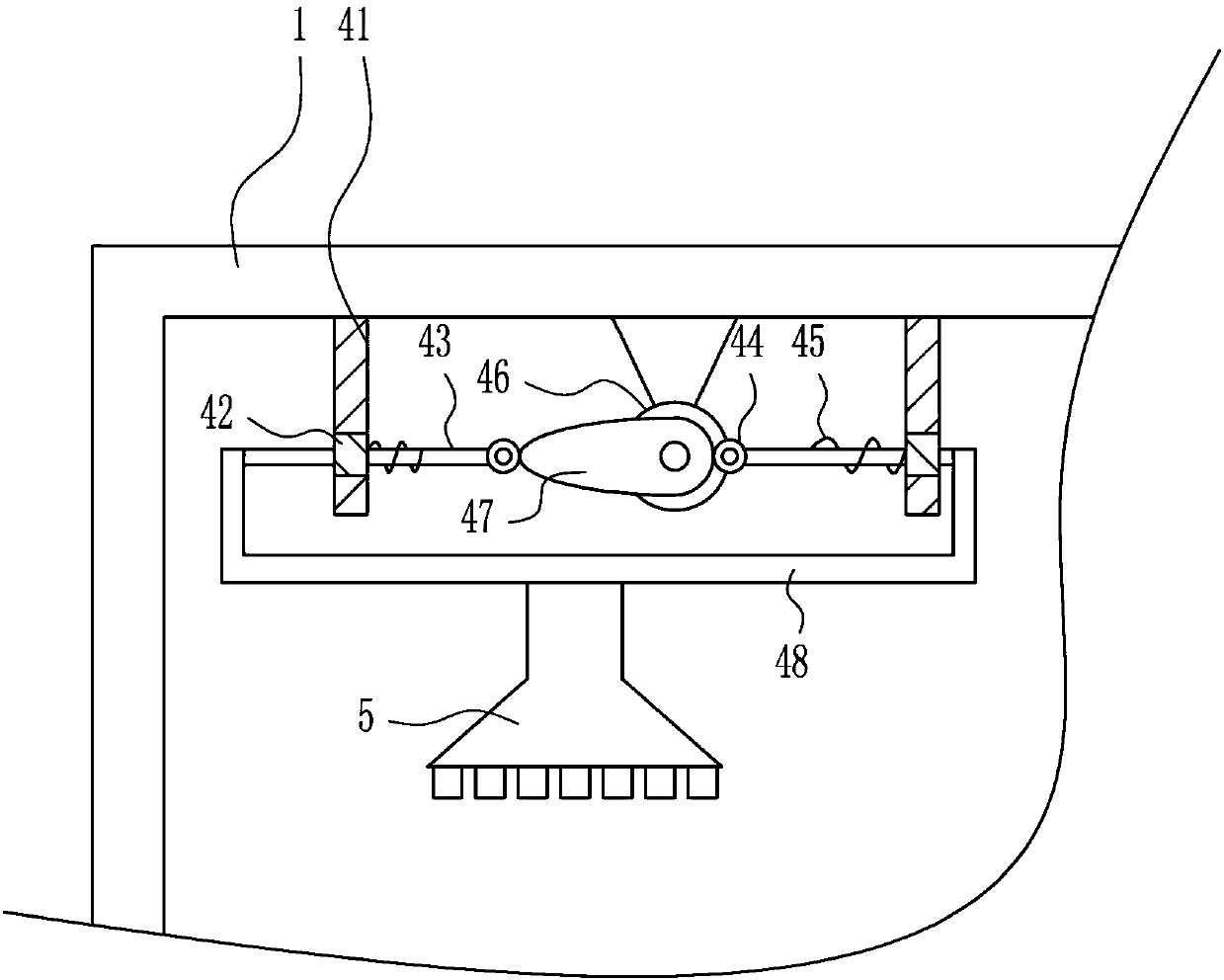

[0029] A spraying equipment for manipulator parts before painting, such as Figure 1-5 As shown, it includes a mounting frame 1, a collection frame 2, a clamping mechanism 3, a left and right moving device 4, and a sprinkler head 5. A collection frame 2 is placed on the left side of the inner bottom of the mounting frame 1, and a clamp is provided on the lower part of the right wall of the mounting frame 1. A holding mechanism 3, a left and right moving device 4 is provided on the left side of the top of the installation frame 1, and a sprinkler head 5 is provided at the bottom of the left and right moving device 4.

Embodiment 2

[0031] A spraying equipment for manipulator parts before painting, such as Figure 1-5 As shown, it includes a mounting frame 1, a collection frame 2, a clamping mechanism 3, a left and right moving device 4, and a sprinkler head 5. A collection frame 2 is placed on the left side of the inner bottom of the mounting frame 1, and a clamp is provided on the lower part of the right wall of the mounting frame 1. A holding mechanism 3, a left and right moving device 4 is provided on the left side of the top of the installation frame 1, and a sprinkler head 5 is provided at the bottom of the left and right moving device 4.

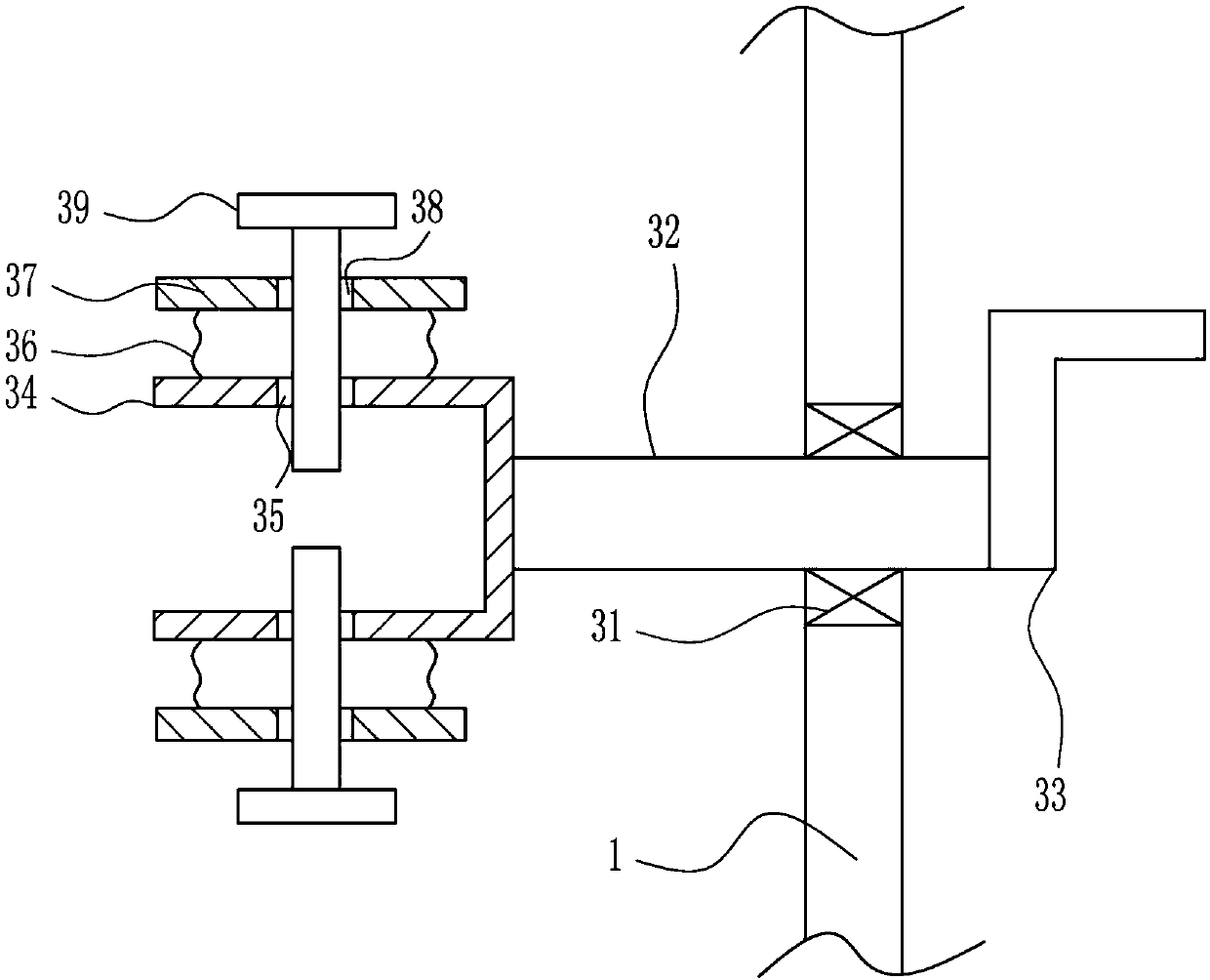

[0032]The clamping mechanism 3 includes a first bearing 31, a first rotating shaft 32, a rocking handle 33, a concave block 34, a first spring 36, a pressing plate 37 and a bolt 39, and the lower part of the right wall of the mounting frame 1 is embedded with the first bearing 31. A bearing 31 is provided with a first rotating shaft 32, the right end of the first...

Embodiment 3

[0034] A spraying equipment for manipulator parts before painting, such as Figure 1-5 As shown, it includes a mounting frame 1, a collection frame 2, a clamping mechanism 3, a left and right moving device 4, and a sprinkler head 5. A collection frame 2 is placed on the left side of the inner bottom of the mounting frame 1, and a clamp is provided on the lower part of the right wall of the mounting frame 1. A holding mechanism 3, a left and right moving device 4 is provided on the left side of the top of the installation frame 1, and a sprinkler head 5 is provided at the bottom of the left and right moving device 4.

[0035] The clamping mechanism 3 includes a first bearing 31, a first rotating shaft 32, a rocking handle 33, a concave block 34, a first spring 36, a pressing plate 37 and a bolt 39, and the lower part of the right wall of the mounting frame 1 is embedded with the first bearing 31. A bearing 31 is provided with a first rotating shaft 32, the right end of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com