Nut conveying and picking device

A technology for picking up devices and nuts, which is applied in the direction of coating, etc., can solve the problems of time-consuming and labor-intensive, small nuts with small volume, etc., and achieve the effects of convenient use, increased work efficiency, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is further described:

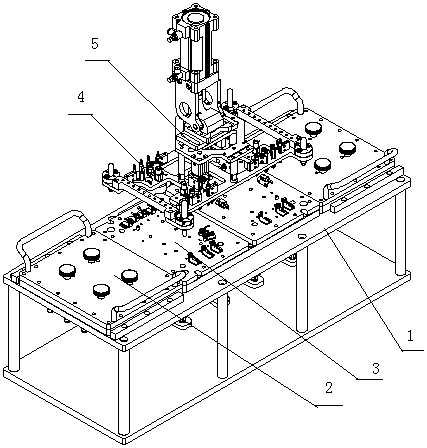

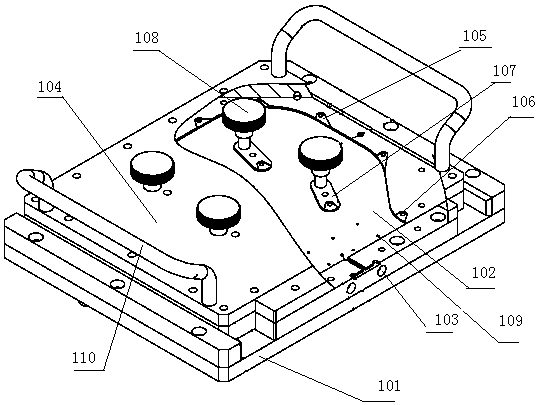

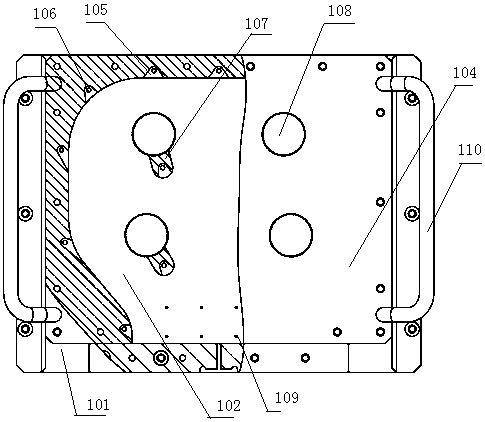

[0029]As shown in the accompanying drawings, a nut conveying and picking device is provided with a platform substrate 1, which is characterized in that the platform substrate 1 is provided with a nut collecting and discharging unit 2, a nut positioning and conveying unit 3, and a nut clamping and picking unit. 4 and the manipulator 5, the nut collection and discharge unit 2 is composed of a discharge base 101 and a discharge cover 102, the discharge base 101 is arranged above the platform substrate 1, and the discharge base 101 is provided with a nut receiving groove 102, The side of described nut receiving groove 102 is provided with nut outlet 103, is provided with discharge cover plate 104 above discharge base 101, and discharge cover plate 104 is connected with the discharge base 101 of nut receiving groove 102 periphery through bolt, discharge cover plate 104 and A nut sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com