Universal appliance tooling for vehicle top luggage rack

A luggage rack and appliance technology, which is applied in the field of auto parts, can solve the problems of resource waste, old-fashioned appliance trolleys cannot meet the requirements of the luggage rack aging process, and items cannot be used universally, and achieve the effect of reducing investment or waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

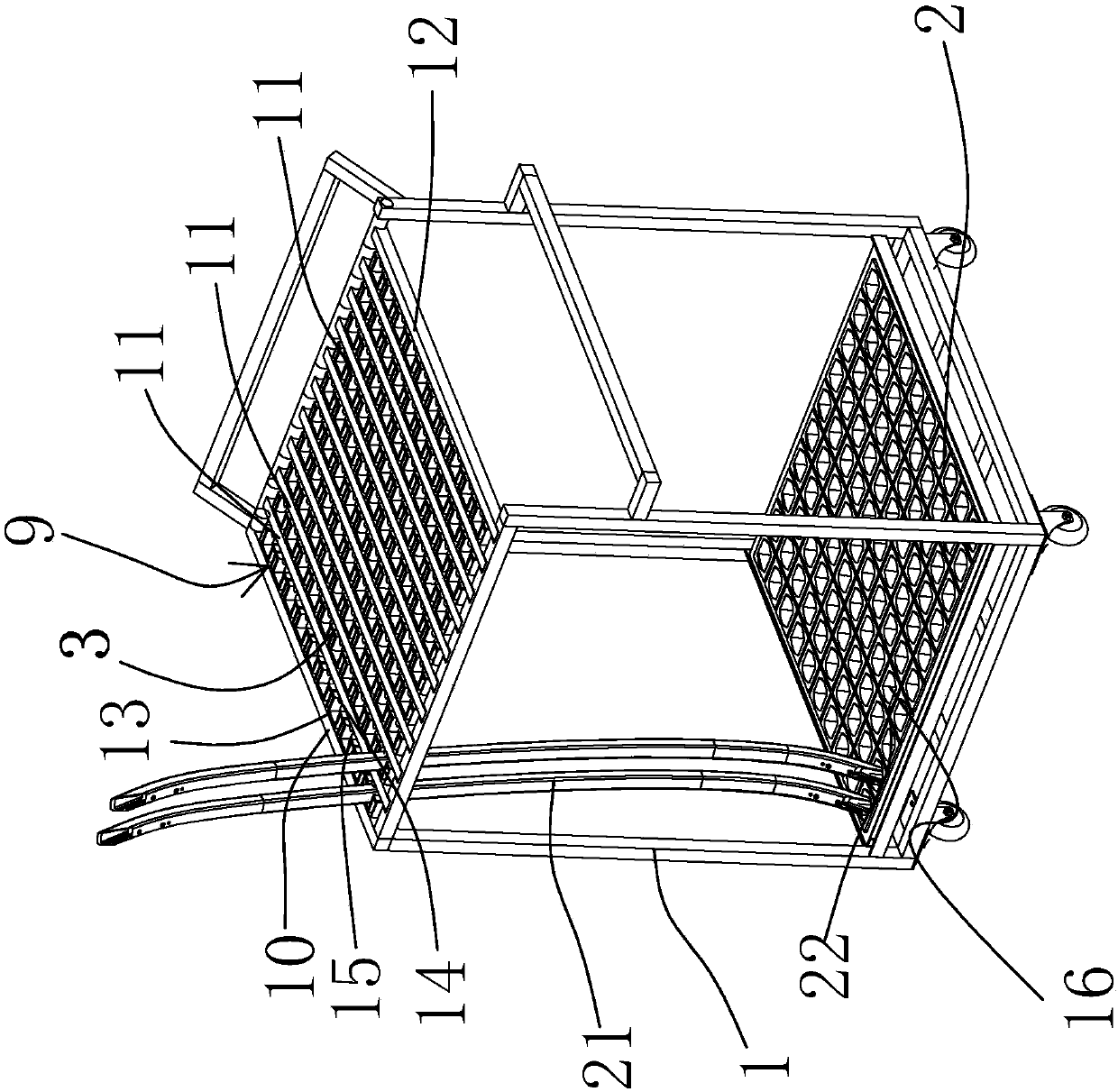

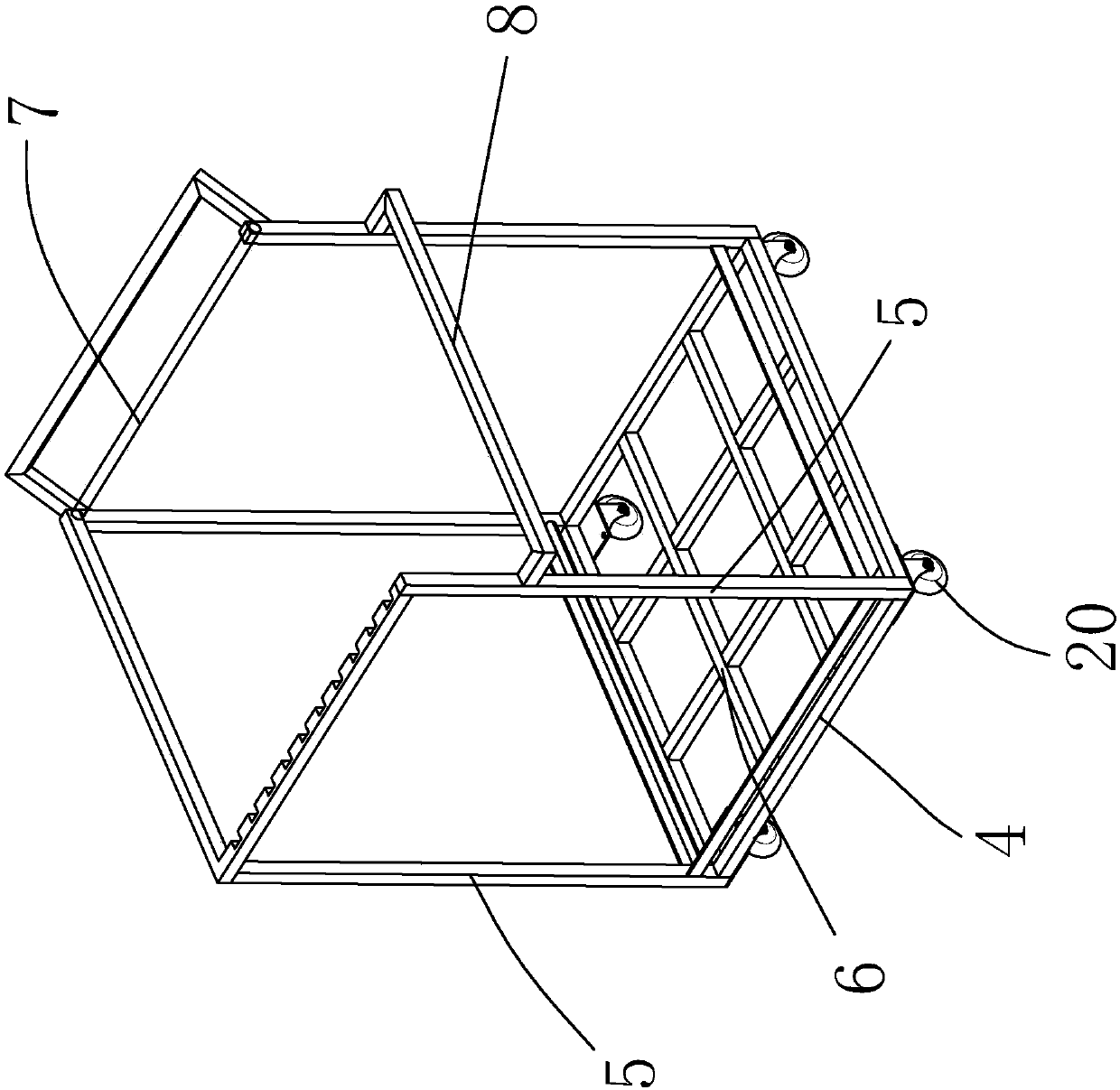

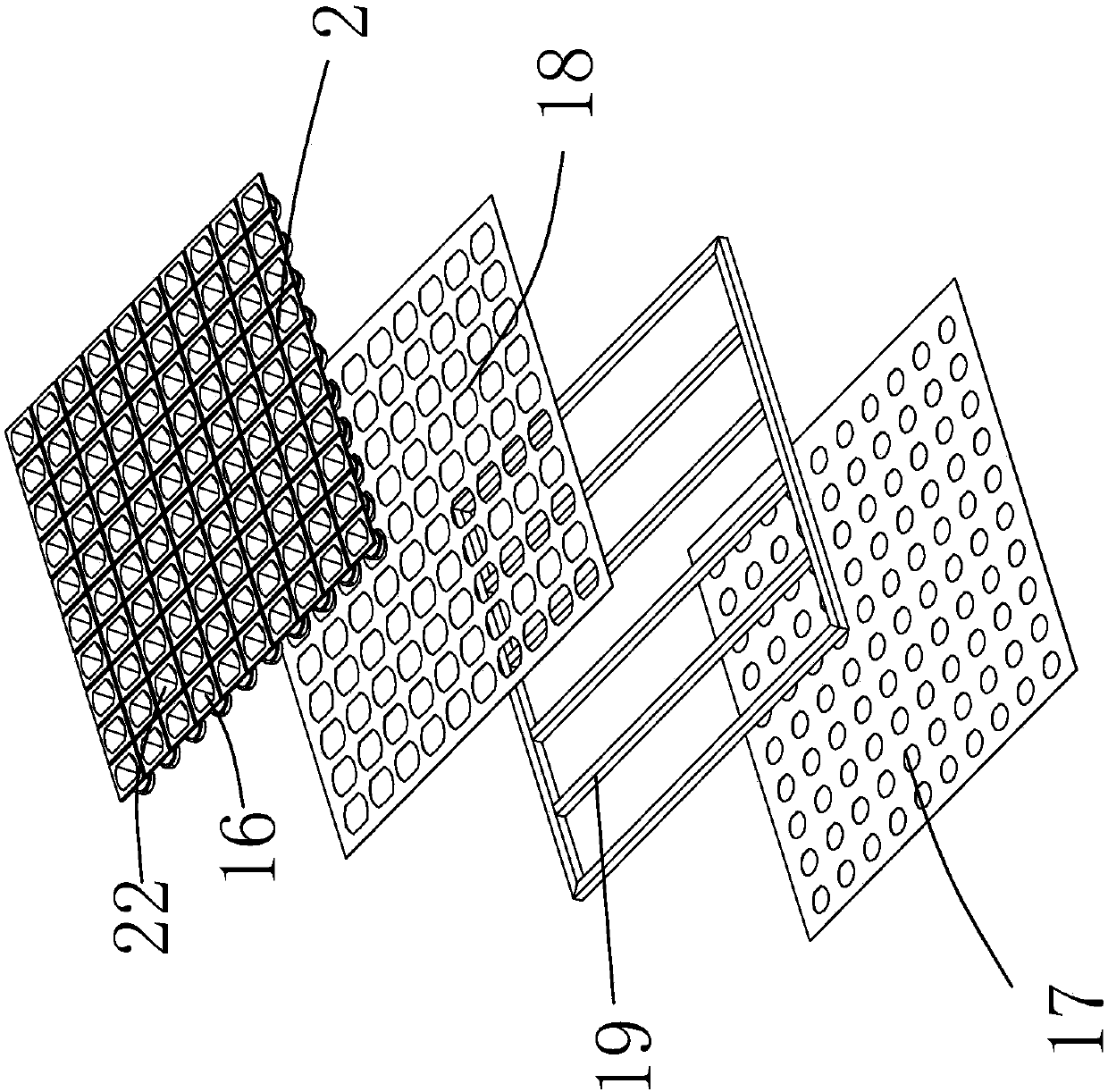

[0020] In the figure, the outer frame part 1; the chassis part 2; the upper fixed part 3; the bottom square tube 4; the column 5; the bottom beam 6; the upper beam 7; Rod 11; three types of stop rod 12; upper high temperature resistant rubber sleeve 13; high temperature resistant block 14; upper fixing hole 15; lower fixing hole 16; first iron sheet 17; second iron sheet 18; supporting chassis 19; casters 20; luggage Frame 21; Lower high temperature resistant plastic sleeve 22.

[0021] Such as figure 1 and Figure 5 As shown, the automotive roof luggage rack universal tooling includes an outer frame portion 1, a chassis portion 2 and an upper fixing portion 3, the chassis portion 2 is arranged at the bottom of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com