CCD detection device with material guiding function

A detection device and material technology, applied in the direction of transportation and packaging, optical testing for flaws/defects, conveyors, etc., can solve problems such as messy placement, speed up detection, and inability to detect in time, so as to improve detection efficiency and reduce entry detection the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

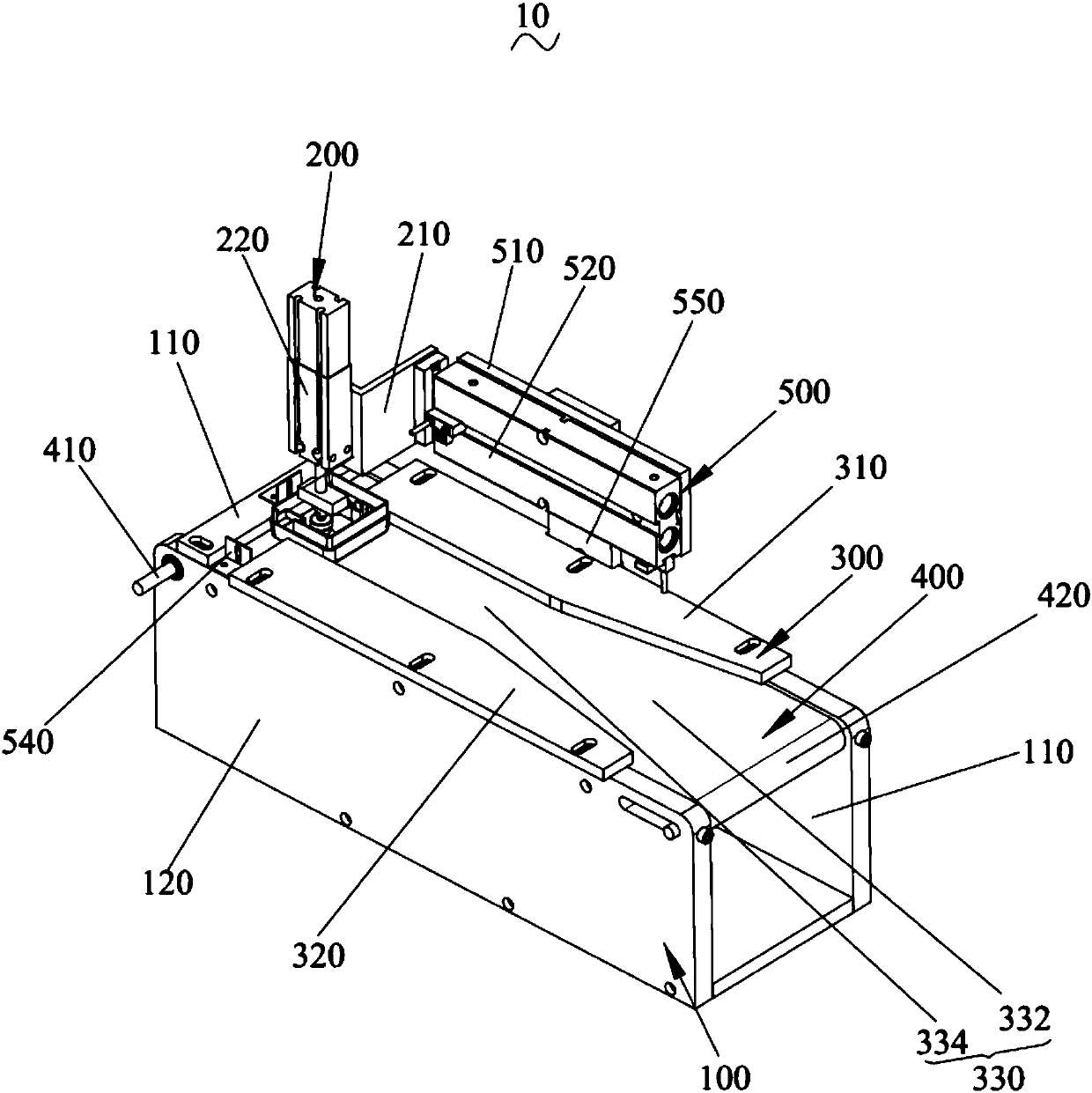

[0022] see figure 1 , the present invention provides a CCD detection device 10 with a material guiding function, comprising: a bracket 100 and a CCD detection unit 200 disposed on the bracket 100 , a guide positioning unit 300 , a horizontal transfer unit 400 and a guide moving unit 500 . It should be noted that the bracket 100 is used to fix the entire CCD detection device; the CCD detection part 200 is used for the CCD detection of the material; the guide positioning part 300 is used for the guide positioning of the material; For conveying materials; the guide moving part 500 is used to move the guide positioning part 300 .

[0023] The bracket 100 includes a first fixing plate 110 , a second fixing plate 120 and a fixing beam 130 fixed between the first fixing plate and the second fixing plate 120 . It should be noted that the fixed beam 130 is fixed to the first fixed plate 110 and the second fixed plate 120 by screws at both ends.

[0024] The CCD detection unit 200 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com