Anaerobic fermentation tank special for fermentation of blueberry with residue

An anaerobic fermentation and slag-carrying technology, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of inability to stir the fermentation liquid, and achieve the effects of increasing the utilization rate of blueberries, reducing the fermentation time, and increasing the fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

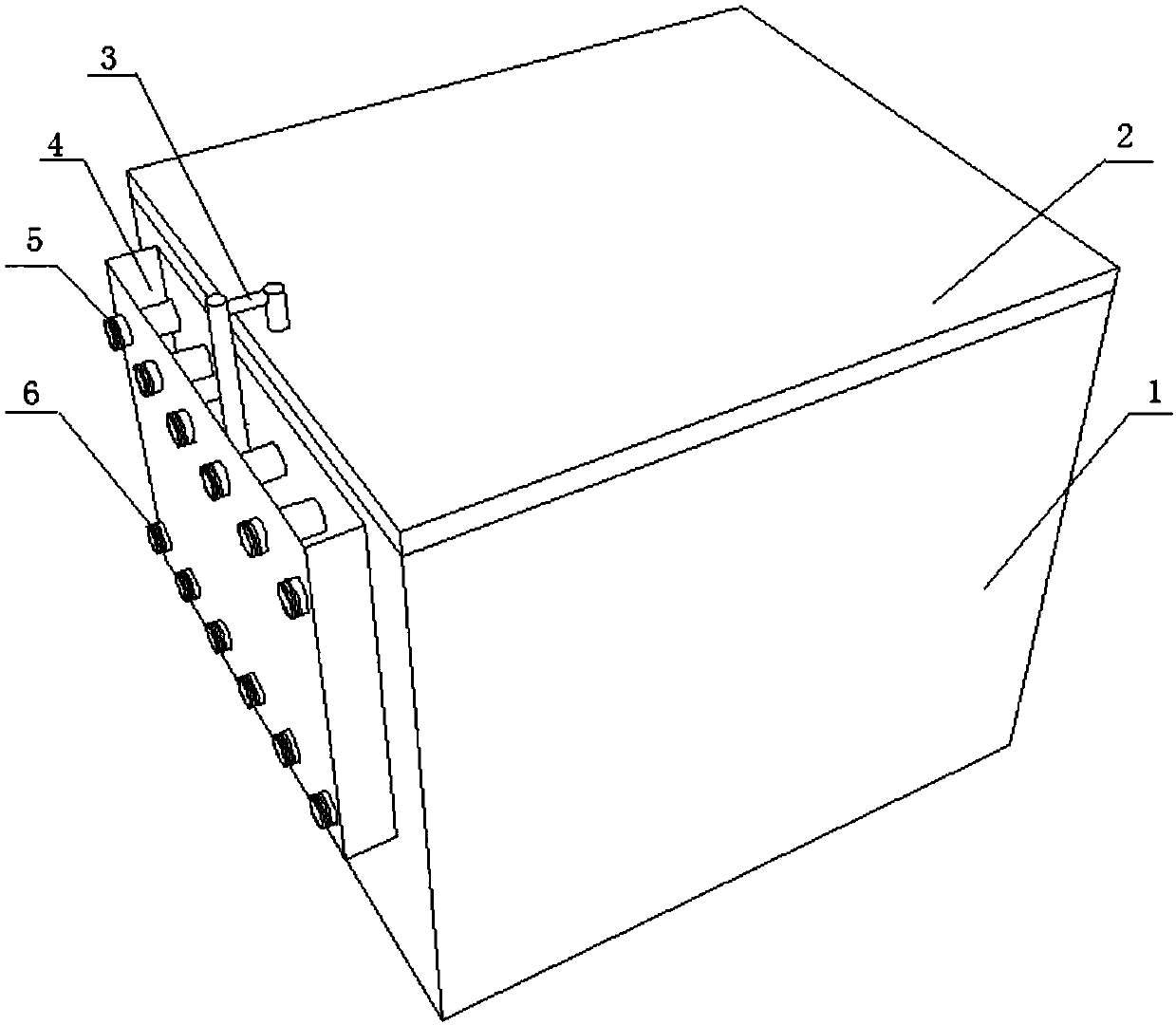

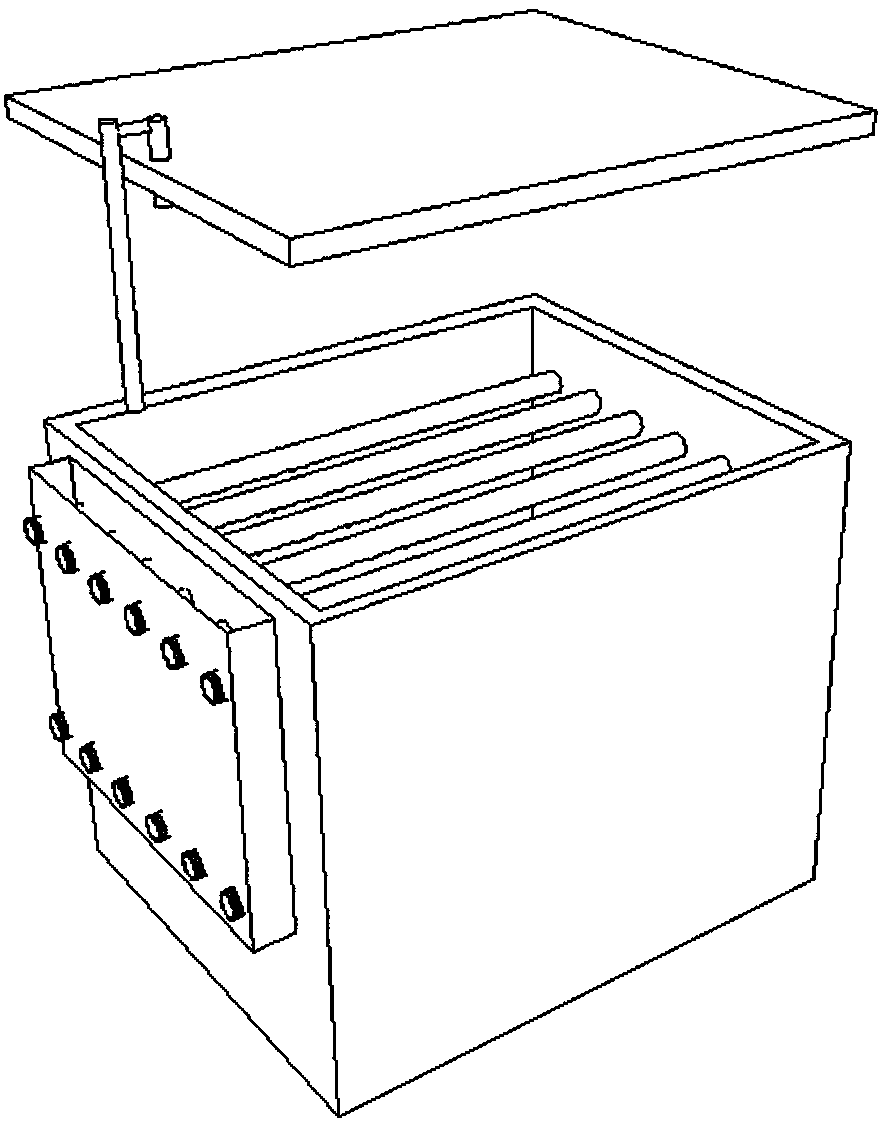

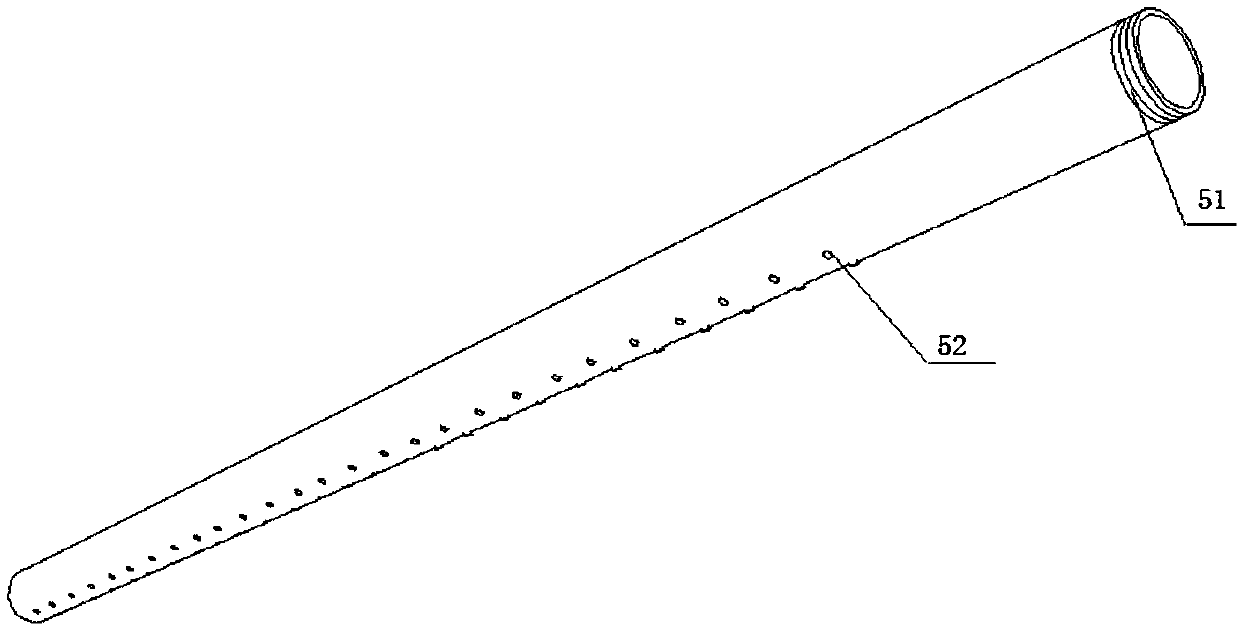

[0021] combine Figure 1-Figure 4 As shown, an anaerobic fermenter specially used for fermentation of blueberries with slag, including a tank body 1 with an upward opening and a cover body 2 sealed and closed on the tank body 1, the upper end of the tank body 1 is provided with several connecting rods The nozzle 5 inside and outside the tank body 1, the nozzle 5 is arranged horizontally, the outer end of the nozzle 5 is arranged to be provided with a nozzle inlet 51 with a threaded protrusion on the outer surface, and the nozzle 5 is located on the side wall inside the tank body 1 A number of nozzle holes 52 for spraying liquid toward the liquid surface are evenly arranged, and a suction pipe 6 corresponding to the nozzle pipe 5 is arranged below the nozzle pipe 5, and the suction pipe 6 is welded by a horizontal pipe section 62 and a vertical pipe section 64 perpendicular to each other. A section of the horizontal pipe section 62 away from the vertical pipe section 64 extends...

Embodiment 2

[0027] Further optimization is obtained on the basis of Example 1. The tank body 1 is located above the liquid level or the cover body 2 is provided with a vent pipe 3 connecting the inside and outside of the tank body 1, and the liquid level in the tank body 1 is lower than the vent pipe. 3 inlets, the outlet of the air release pipe 3 is located in an open liquid seal box 4, and the outlet of the air release pipe 3 is lower than the liquid level in the liquid seal box 4, the present embodiment is about the liquid seal box 4 and the air release pipe 3 The setting is convenient for the carbon dioxide produced in the fermentation process to be discharged in time, and at the same time prevents outside air from entering the tank body 1, so as to avoid extra oxygen and impurities in the air from affecting the fermentation effect.

Embodiment 3

[0029] Further optimization is obtained on the basis of Example 2. The liquid seal box 4 is fixed on the side wall of the tank body 1, and the nozzle pipe 5 and the suction pipe 6 are located outside the tank body 1. Part of the pipe section traverses the liquid seal box 4. This implementation For example, with regard to the setting of the spray pipe 6, the suction pipe 5 and the liquid seal box 4, the fermented liquid can be cooled in the pipe section crossing the liquid seal box 4 during the circulation process, thereby further facilitating the dissipation of the heat of the fermented liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com