Method for producing three-dimensional honeycomb-type cloth by using viscose short fiber and viscose filaments

A three-dimensional, short-fiber technology, which is applied to textiles, papermaking, fabrics, textiles, etc., can solve the problems of large material limitations, limited use range, and low functionality, and achieve strong cleaning power, strong self-cleaning power, Stronger detergency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

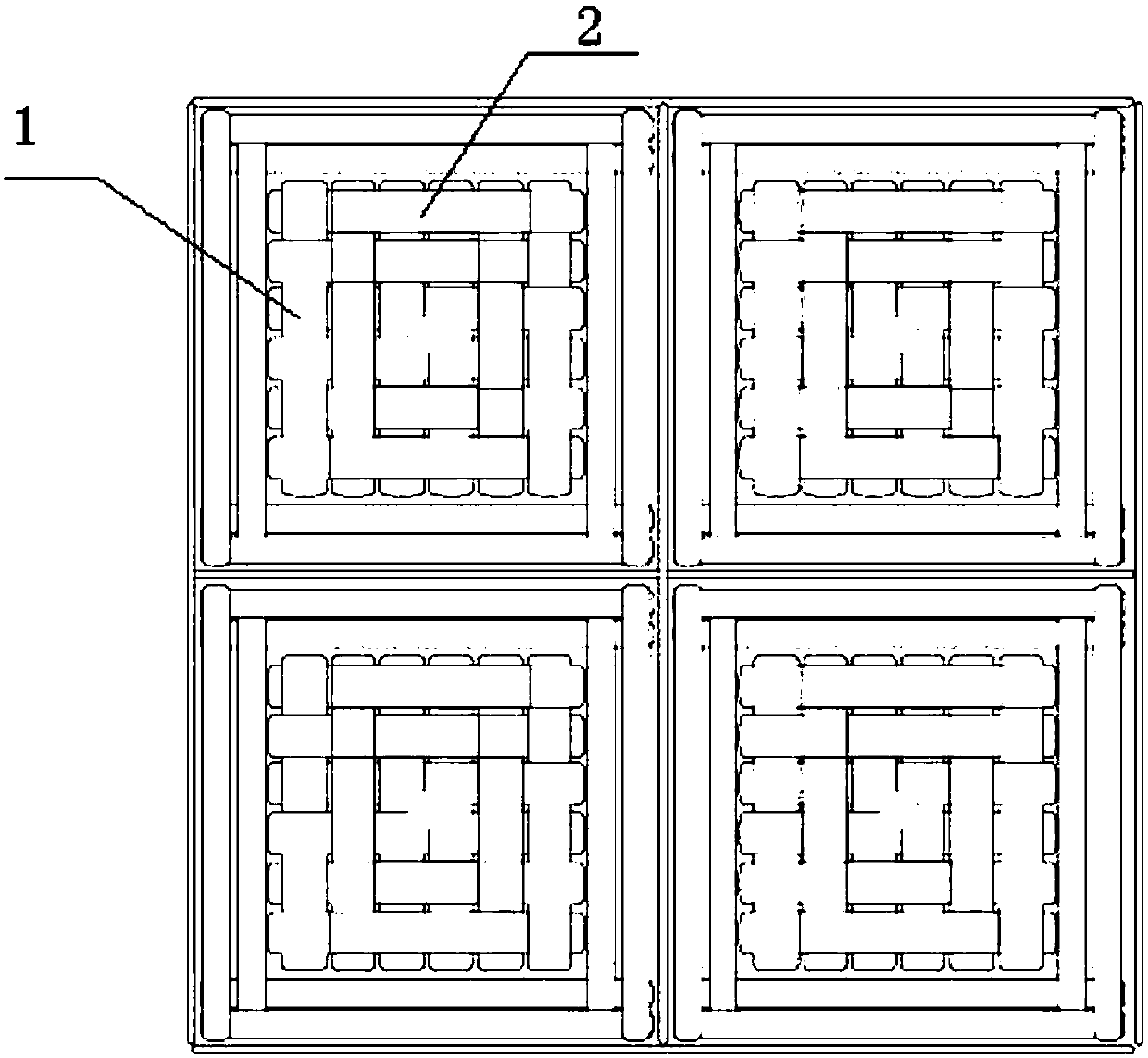

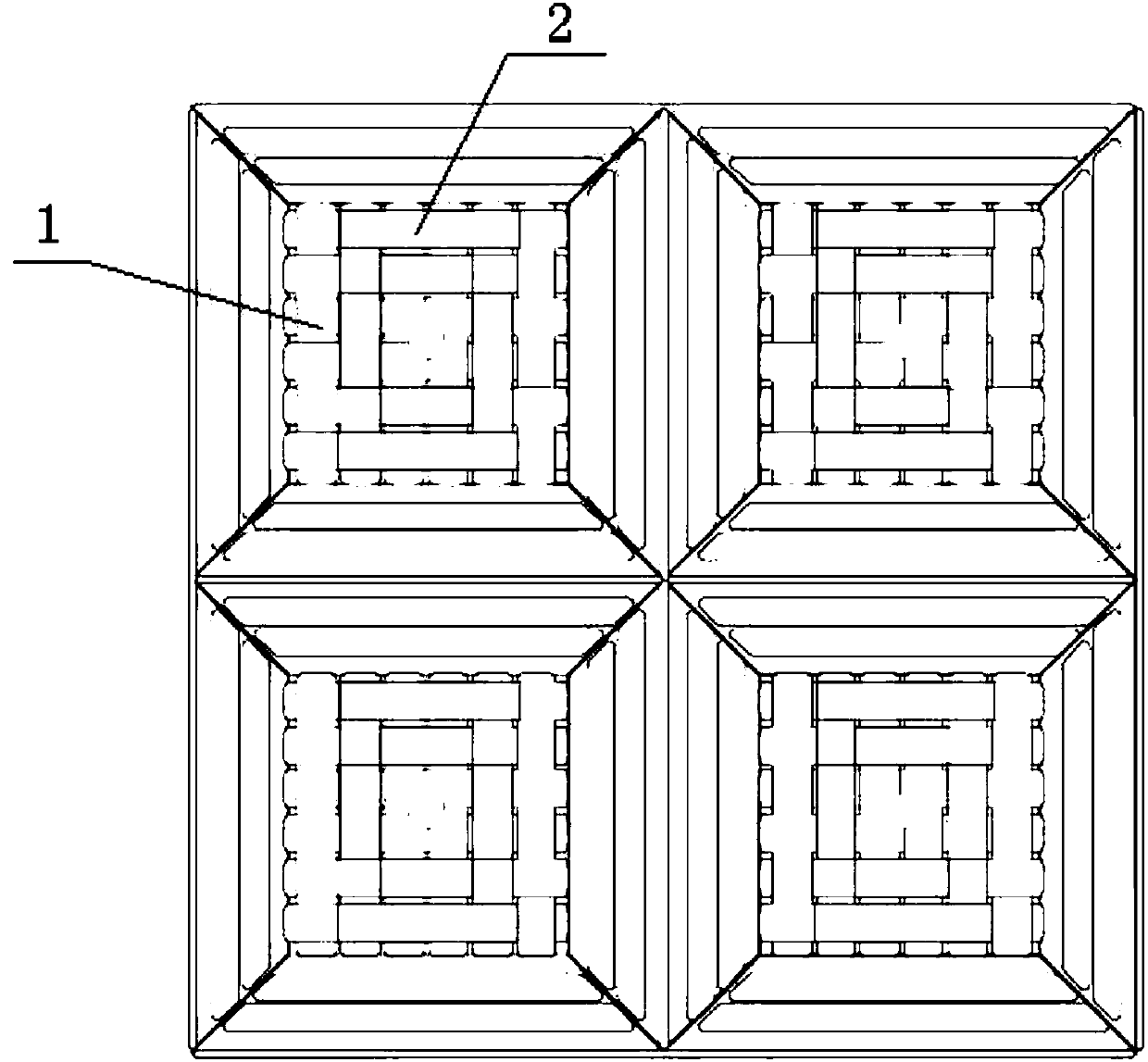

[0026] As shown in the figure, 20 double-strand 18-twist viscose staple fiber yarns are selected as warp 1, and warp 1 is dull; 333.3dtex / 30f glossy flat viscose filaments are selected as weft 2, and weft 2 is glossy.

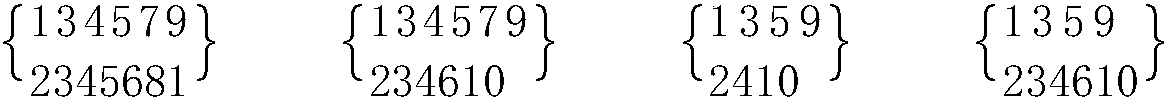

[0027] The rapier loom uses 5 heald frames and 25 steel buckles to weave light and dark star-shaped cloth, which produces star-shaped characteristics of light (weft points) and dark (longitude points) on the cloth. The density of warp yarns in weaving is 56 per pair; the density of weft yarns is 43 per pair, and the number of heald frames is 8. The organizational structure is as follows:

[0028]

[0029] The woven cloth is dyed and finished, and then cut, sewn, and packaged according to different uses into finished products.

[0030] The warp yarn 1 is a twisted rubber yarn and the weft yarn 2 is a non-twisted filament. The shrinkage rate of the two is very different, which makes the fabric structure change after being immersed in water, that is, from a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com