An assembly device that facilitates the assembly of plastic bearings

A technology for assembling equipment and plastic bearings, which is applied to shafts and bearings, bearing components, mechanical equipment, etc. It can solve the problems of difficulty in guaranteeing bearing quality, inability to guarantee the concentricity of inner and outer rings, and achieve accurate and fast assembly, ensuring coaxiality, The effect of ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

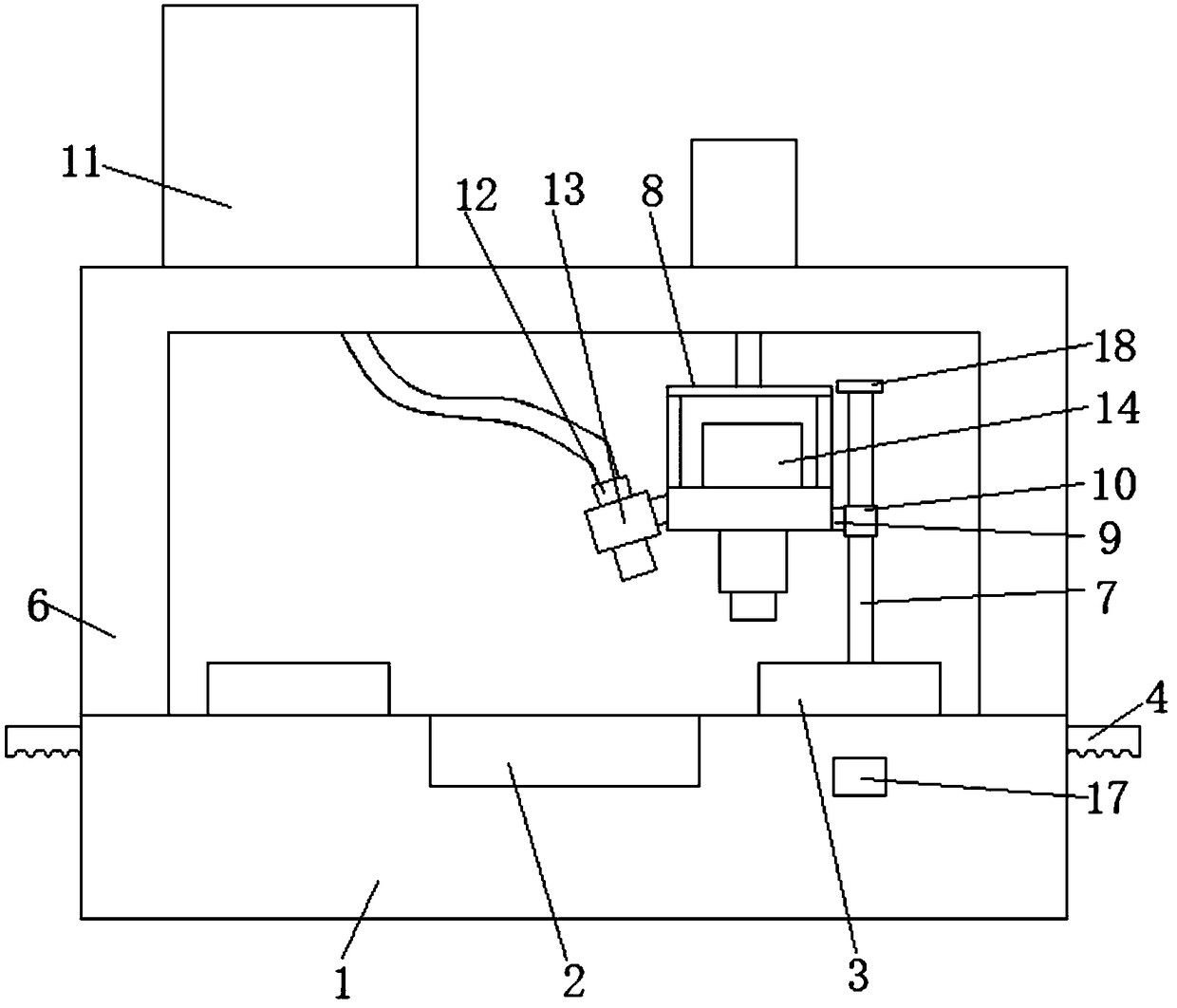

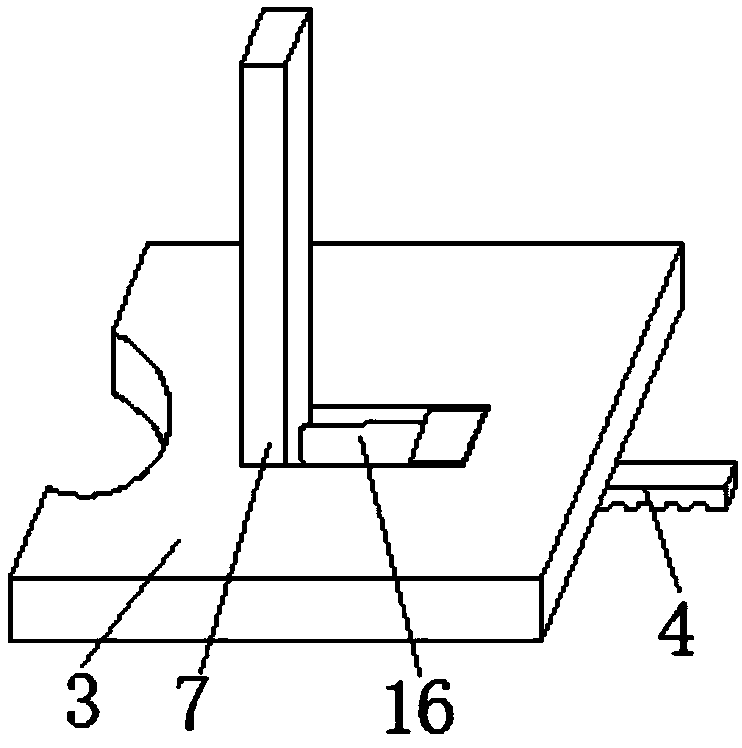

[0027] refer to figure 1 , 3 , 4 and 5, a kind of assembly equipment that is convenient for plastic bearing assembly, comprises frame 1, and described frame 1 is provided with conveyer belt 2, and both sides of described conveyer belt 2 are provided with fixing splint 3, two sets of fixing splint 3 The center of one side close to the conveyor belt 2 is provided with a semicircular positioning groove. The bottom of the fixed splint 3 is provided with a guide rack 4. The fixed splint 3 is slidably connected with the frame 1 through the guide rack 4. The frame 1 is provided with The guide chute matched with the guide rack 4, and the center of the bottom of the guide chute is provided with a transmission gear 5, the frame 1 is provided with a rotating groove matched with the transmission gear 5, and the frame 1 is provided with a drive motor 17 , and the output end of the driving motor 17 is connected with the transmission gear 5, and the side of the two sets of fixed splints 3 a...

Embodiment 2

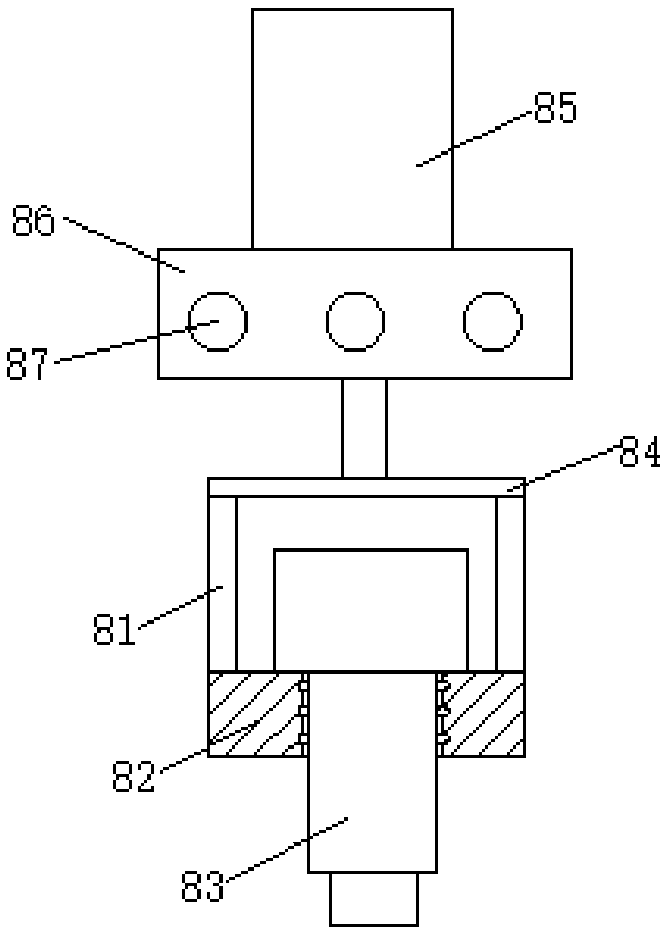

[0030] refer to figure 1 , 2And 6, the inner ring positioning mobile device 8 includes a lifting rod 81, a support plate 82, a positioning rotary head 83, a lifting plate 84, an electric telescopic rod 85, a moving seat 86 and a rolling steel ball 87, and the supporting frame 6 is provided with a moving seat 86 Matching moving chute, and both sides of moving seat 86 are provided with rolling steel ball 87, and the top of moving seat 86 is provided with electric telescopic rod 85, and the output end of described electric telescopic rod 85 passes through moving seat 86 and is connected with lifting Plate 84, lifting plate 84 is vertically connected with two groups of lifting rods 81 away from the side of electric telescopic rod 85, two groups of lifting rods 81 are vertically connected with support plate 82 away from one end of lifting plate 84, and supporting plate 82 is far away from one end of lifting rod 81. The side rotation is connected with a positioning rotary head 83, ...

Embodiment 3

[0032] refer to figure 1 , 2 , 3, 4, 5 and 6, use the electric push rod 16 to push the guide vertical rod 7 back to the original position, and start the drive motor 14 at the same time to rotate the positioning rotary head 83, so that the steel balls are filled into the raceways of the inner and outer rings of the bearing, and the positioning is completed Finally, use the electric telescopic rod 85 to lift the lifting plate 84, the lifting rod 81 to lift the support plate 82, and finally start the drive motor 17 to make the transmission gear 5 reversely rotate, so that the fixed splint 3 leaves the outer ring of the bearing. Use the conveyor belt 2 to move the ball-filled bearing to the next assembly process, use the cooperation of the electric push rod and the guide vertical rod to push the positioning rotary head back to its original position, and start the drive motor at the same time to rotate the positioning rotary head, positioning the rotary head belt The rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com