Air relief valve for electrically controlled tire explosion avoiding system

A technology for air release valve and tire blowout, which is applied in the field of air release valve of an electronically controlled tire blowout avoidance system, can solve problems such as reducing the degree of danger, and achieve the effects of ensuring safety, improving braking ability and good air sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

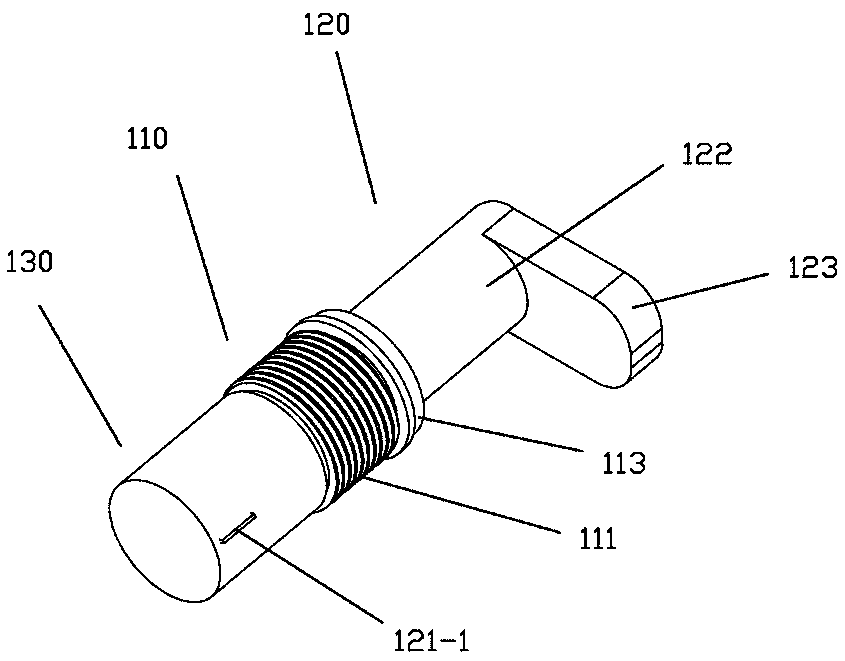

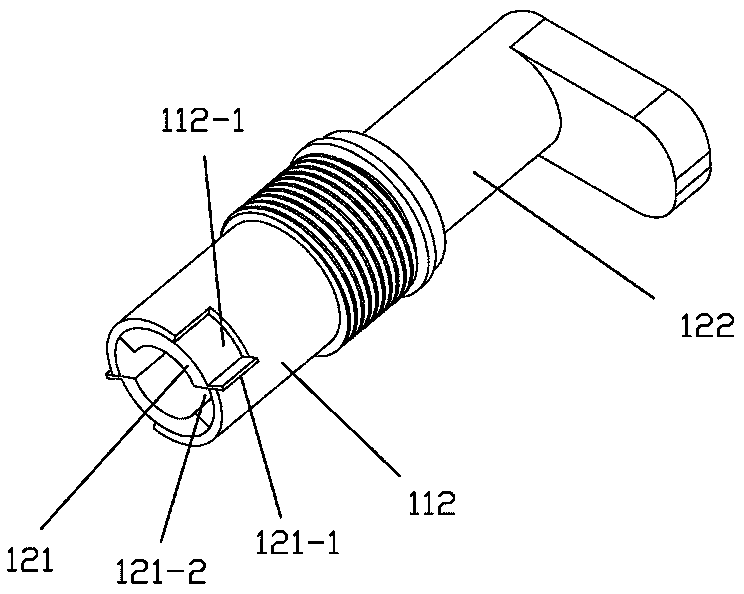

[0037] Such as Figure 1-2 As shown, the deflation valve used in the electronically controlled tire blowout avoidance system includes a valve body 110 and a valve core 120; the valve body 110 is used to fix the deflation valve to the tire and facilitate the setting of the valve core 120 . The valve core 120 is partially sleeved inside the valve body 110 and partially protrudes from the valve body 110 .

[0038] The valve body 110 includes a mounting portion 111 , an internal portion 112 and an external portion 113 , and a notch 112 - 1 is provided on a side of the internal portion 112 .

[0039] The valve core 120 is a hollow structure with an air release channel, and is rotatably sleeved inside the valve body 110 , including a valve core body internal part 121 , a valve core body external part 122 and an action part 123 .

[0040] The side of the built-in portion 121 of the valve core body is also provided with a breaking piece 121-1, and the breaking piece 121-1 is set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com