A high-strength, creep-resistant municipal inspection manhole cover and its preparation method

A creep-resistant, inspection well technology, applied in polymer-based municipal inspection manhole covers, creep-resistant municipal inspection manhole covers, and polyethylene waste plastic-based high-strength fields, can solve the problem that polymer-based municipal inspection manhole covers are not suitable for use, inspection manhole covers creep Change, check the sinking of the manhole cover and other problems, to achieve the effect of broadening the scope of use, inhibiting flow, and easy to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

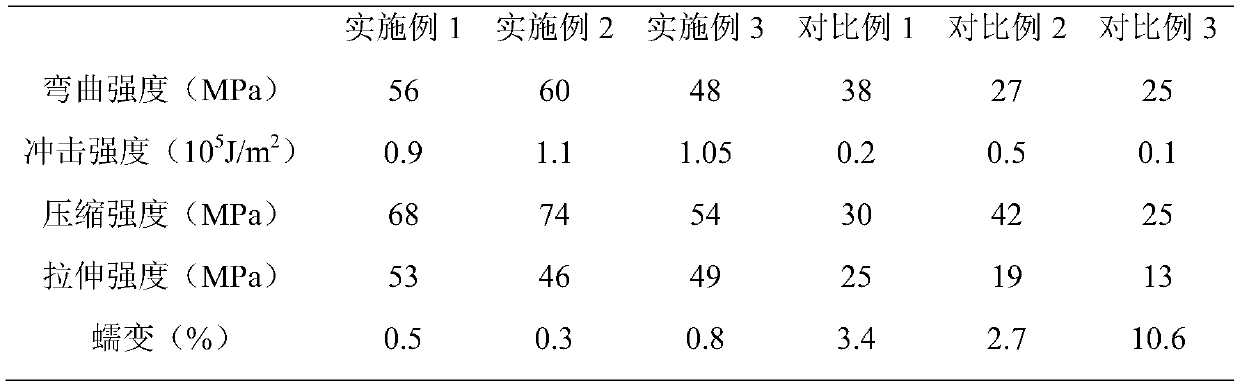

Examples

Embodiment 1

[0038] Preparation of polyolefin grafted nanoporous inorganic filler: 1) nanoporous diatomite is placed in the plasma generating device, the power is turned on, and the discharge power is adjusted. The flow rate of the gas medium is 55mL / min, and the discharge time is 15min. 2) transfer the material obtained in step 1) to a vacuum reactor, add isobutylene and mix; 3) raise the temperature of the reactor to 150 ° C, under the protection of an inert gas, condense and reflux for 20 hours to obtain poly Isobutylene grafted nanoporous diatomaceous earth.

[0039] The mass parts of each raw material component of the high-strength, creep-resistant municipal inspection manhole cover are: 40 parts of polyethylene waste plastic, 90 parts of polyisobutylene grafted nanoporous diatomite, 5 parts of wear-resistant agent, 2.5 parts of anti-aging agent, flame retardant 3 parts of agent, 2 parts of pigment.

[0040] Preparation of municipal inspection manhole cover: 1) Stir and mix the polye...

Embodiment 2

[0044] Preparation of polyolefin-grafted nanoporous inorganic filler: 1) Nanoporous bentonite is placed in the plasma generator, the power is turned on, and the discharge power is adjusted. The flow rate of the gas medium is 45mL / min, and the discharge time is 10min. Surface treatment; 2) Transfer the substance obtained in step 1) to a vacuum reactor, add 1,3-pentadiene and mix; 3) Raise the temperature of the reactor to 150°C, and condense and reflux for 20 hours under the protection of an inert gas , that is, poly-1,3-pentadiene grafted nano-porous bentonite.

[0045] The mass parts of each raw material component of the high-strength and creep-resistant municipal inspection manhole cover are: 60 parts of polyethylene waste plastics, 80 parts of poly-1,3-pentadiene grafted nano-porous bentonite, 10 parts of wear-resistant agent, and 3 parts of anti-aging agent 1 part, 4 parts of flame retardant, 1 part of pigment.

[0046]The preparation of the municipal inspection manhole c...

Embodiment 3

[0048] Preparation of polyolefin grafted nanoporous inorganic filler: 1) nanoporous vermiculite is placed in the plasma generating device, the power is turned on, and the discharge power is adjusted. The flow rate of the gas medium is 70mL / min, and the discharge time is 10min. 2) transfer the substance obtained in step 1) to a vacuum reactor, add 4-ethylpentene and mix; 3) raise the temperature of the reactor to 300°C, and condense and reflux for 10 hours under the protection of an inert gas , That is, poly-4-ethylpentene grafted nanoporous vermiculite.

[0049] The mass parts of each raw material component of the high-strength and creep-resistant municipal inspection manhole cover are: 80 parts of polyethylene waste plastics, 60 parts of poly-4-ethylpentene grafted nanoporous vermiculite, 8 parts of wear-resistant agent, and 2 parts of anti-aging agent 5 parts, 5 parts of flame retardant, 3 parts of pigment.

[0050] The preparation of the municipal inspection manhole cover:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com