Wood frame-orthogonal laminated wood shear wall connected by energy-dissipation connector in continuous beams

A technology of glulam and shear wall, which is applied in the direction of building components, building types, buildings, etc., can solve the problems of system stiffness and bearing capacity reduction, and achieve the effect of improving energy consumption capacity and limit displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

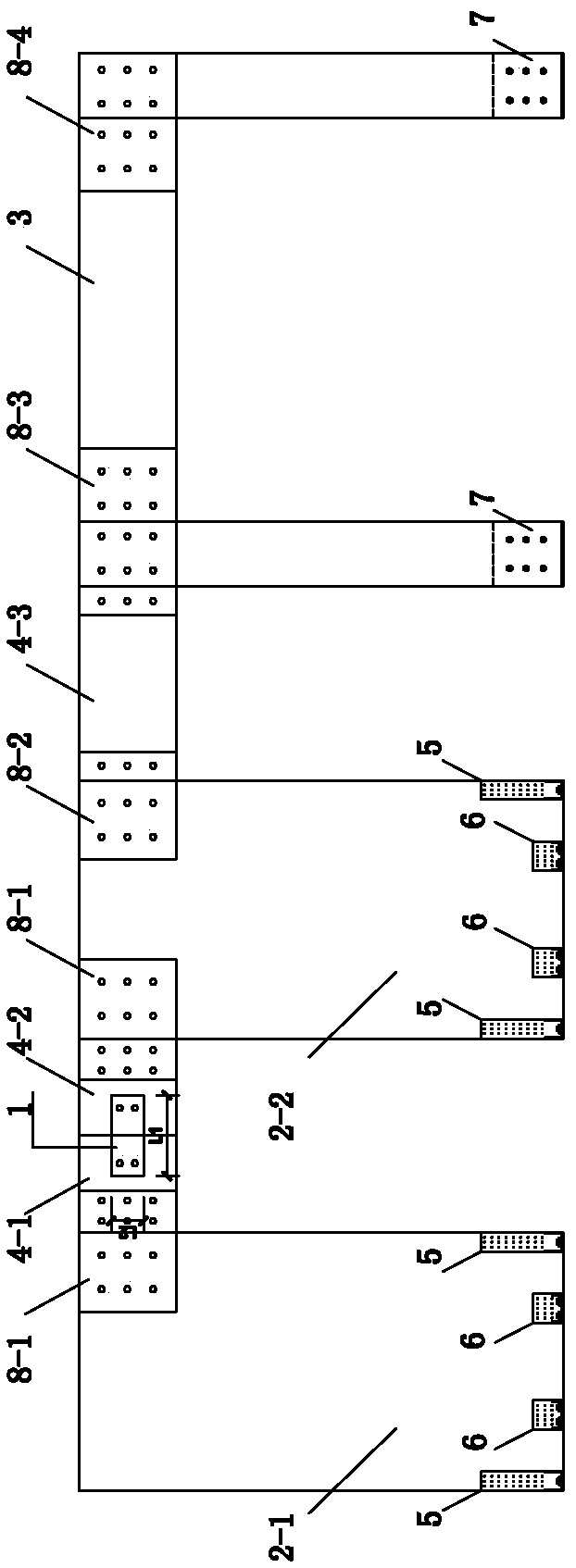

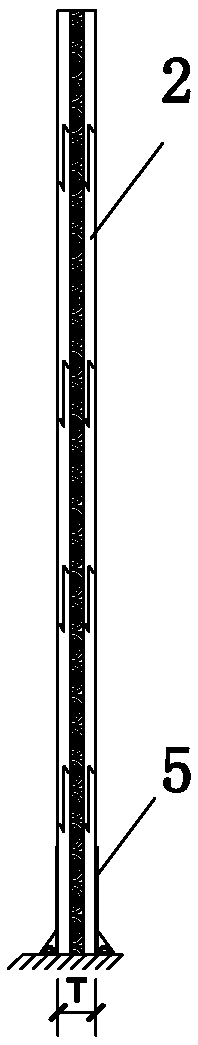

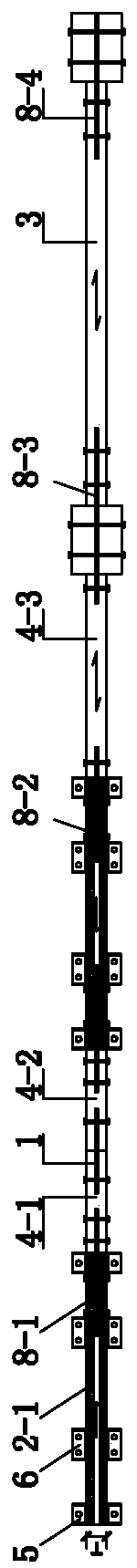

[0031] like Figure 1-9 shown.

[0032] A wood frame-orthoglued wood shear wall connected by energy-dissipating connectors in the coupling beams, such as Figures 1 to 3 As shown, it includes energy-dissipating metal connector 1, cross-glued wood shear wall 2, glued-laminated wood frame 3, first glued-laminated wood connecting beam 4-1, second glued-laminated wood connecting beam 4-2 and metal connecting piece 5, 6, 7, 8, the connecting beams between the shear walls are spliced vertically to form vertical joints, and the energy-dissipating metal connector 1 straddles the vertical joints and simultaneously connects with the first glulam connecting beam 4-1 and the second Glulam coupling beam 4-2 connection;

[0033] The cross-laminated timber shear walls 2-1 and 2-2, and the glued-laminated timber frame 3 are assembled on beams or floor slabs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com