Vertical multi-tube bundle type forced-cooling vortex tube cold-heat separation device

A technology of forced cooling and separation of cold and heat, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as difficult collection and recycling of heat, space saving of vertical structure, difficulty of horizontal balance, etc., and reach the structural size range Wide, simple and feasible structure, easy to guarantee the accuracy of manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

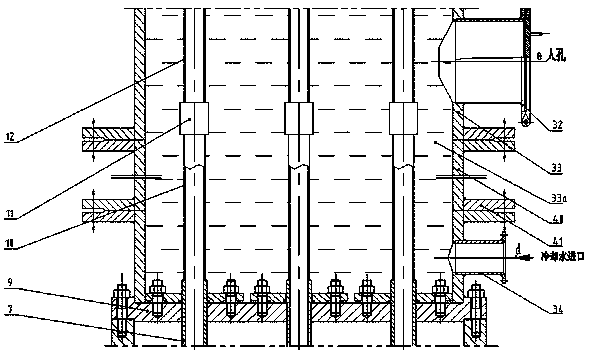

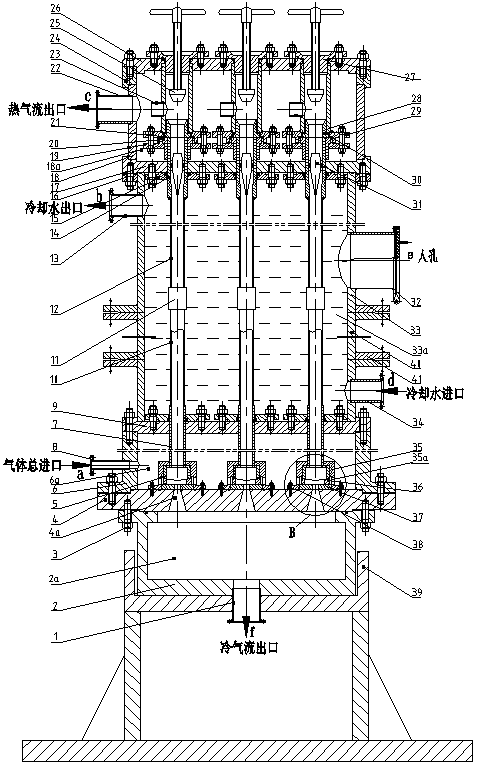

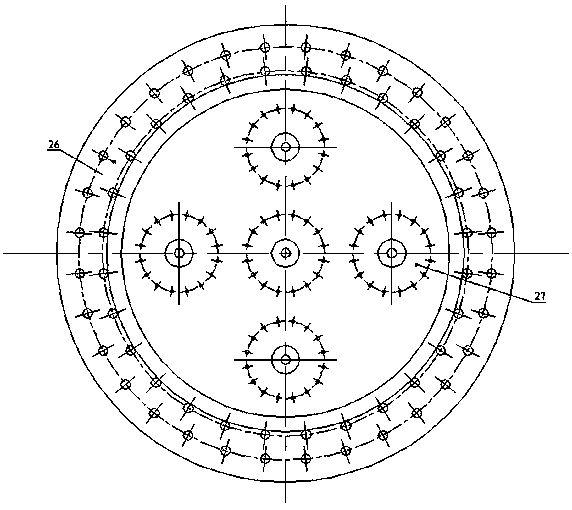

[0028] figure 1 , 2 , 3, 4, and 5 show a structural diagram of a vertical multi-tube bundle forced cooling vortex tube cold and heat separation device. In the figure, the device as a whole has a vertical multi-tube bundled structure, and consists of four chambers from top to bottom: the hot end collection chamber 18a, the water cylinder jacket chamber 33a, the air intake chamber 6a and the cold air collection chamber 2a , the hot end collection chamber 18a is formed by the fixed connection of the hot chamber shell 18 and the lower end cover 17 of the hot chamber, the upper flange 24 of the hot chamber and the upper end cover 26 of the hot chamber; , a replaceable barrel nipple 40, a connecting flange 41, an air intake chamber cover 9, an upper flange 16 of the water tank jacket and a lower end cover 17 of the thermal chamber are fixedly connected; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com