Parameterized false tooth coronal internal surface generation method

An internal surface and parametric technology, applied in the field of denture restoration, can solve problems such as non-consistency, adhesive thickness, and adhesive thickness cannot be controlled, and achieve high precision, less calculation, and the most excellent fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

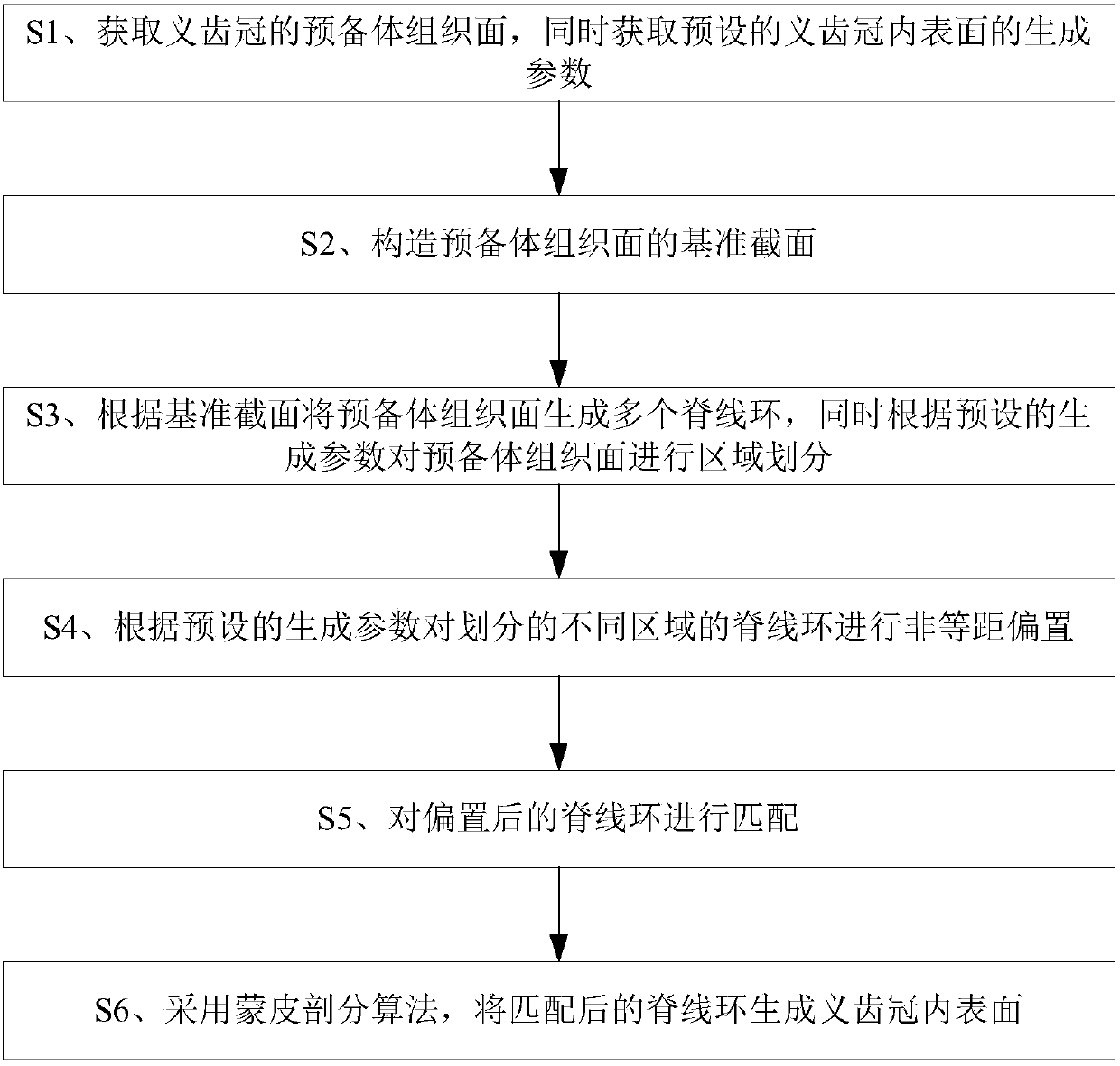

[0069] refer to figure 1 , the present invention provides a parameterized method for generating the inner surface of a denture crown, comprising the steps of:

[0070] S1. Obtain the preparation tissue surface of the denture crown, and obtain the preset generation parameters of the inner surface of the denture crown at the same time;

[0071] S2, constructing the reference section of the tissue surface of the preparation body;

[0072] S3. Generate a plurality of ridge line rings on the tissue surface of the preparation according to the reference section, and at the same time divide the tissue surface of the preparation into regions according to preset generation parameters;

[0073] S4. Perform non-equidistant offset on the ridge line rings of different divided regions according to the preset generation parameters;

[0074] S5. Matching the offset ridge ring;

[0075] S6, using the skin subdivision algorithm to generate the inner surface of the denture crown from the match...

Embodiment 2

[0113]The present invention is a detailed example of Embodiment 1, specifically comprising the following steps:

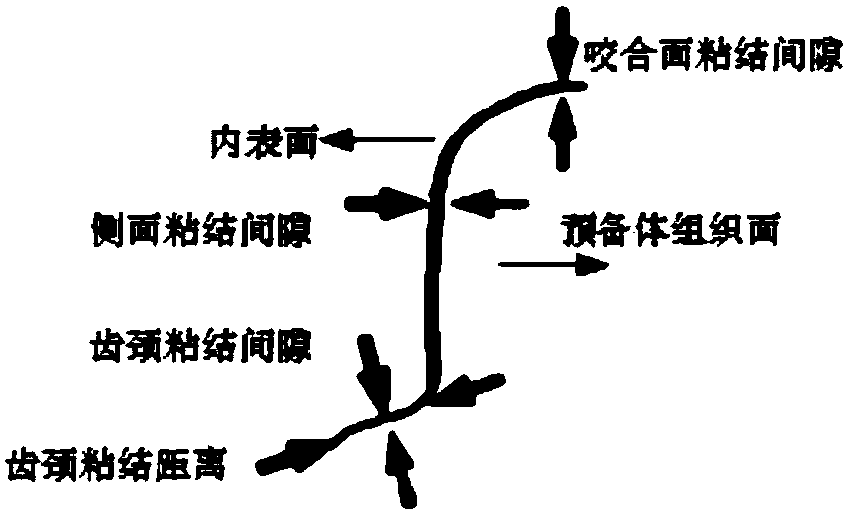

[0114] Step 1: Obtain the preparation tissue surface of the denture crown, and simultaneously acquire the preset generation parameters of the inner surface of the denture crown. The acquired tissue surface of the prepared body is a triangular mesh model, and the triangular network model can be obtained by using a triangulation method in the prior art. like figure 2 As shown, the generation parameters include the occlusal surface bonding gap top_offset, the side bonding gap side_offset, the tooth neck bonding gap bottom_offset, and the tooth neck bonding distance bottom_length.

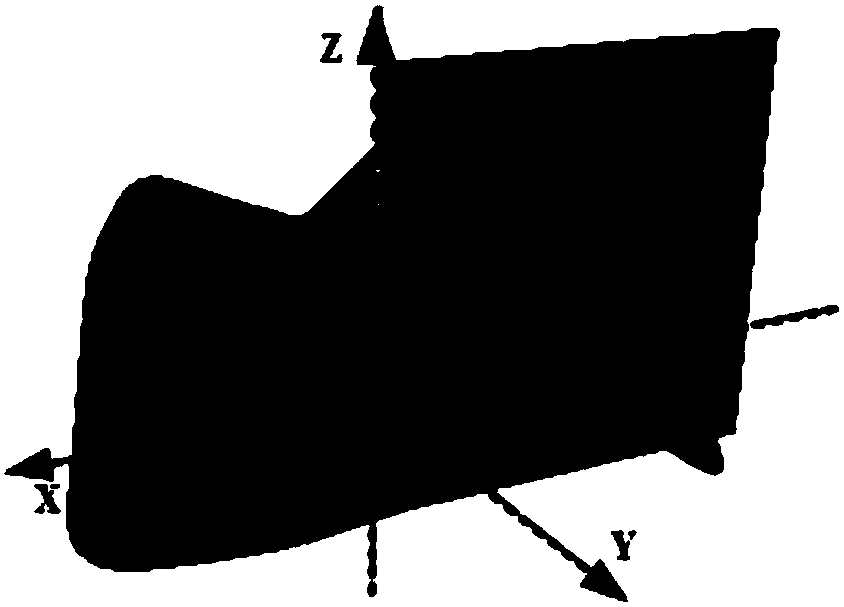

[0115] Step 2, constructing the reference section of the tissue surface of the prepared body; specifically: as image 3 As shown, the plane where the X-axis and Z-axis of the tissue surface of the preparation body are located is taken as the initial cross-section, and the Z-axis of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com