Suction tube for sucking liquid foods

A liquid food and straw technology, which is applied to table utensils, home utensils, table utensils, etc., can solve problems such as inability to drink, end of porridge, environmental pollution, and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

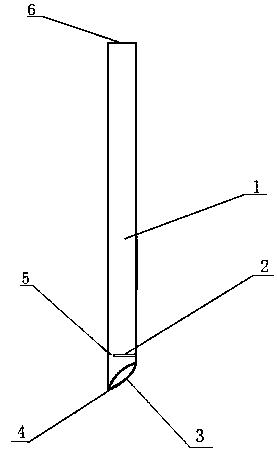

[0008] exist figure 1 Among them, a straw for absorbing liquid food provided by the present invention is a plastic cylindrical empty tube, including a suction rod 1, the upper opening of the suction rod 1 is a flat cutout 6, the lower opening of the suction rod 1 is an oval oblique cutout 3, and the oblique cutout The end of 3 is a thorn point 4, and the thorn point 4 is used to pierce the sealing film of the container; it is characterized in that: a transverse incision 2 is set at the lower end of the suction rod 1 close to the top of the oblique incision 3, and a connecting section 5 is left, and the suction rod 1 is not placed The rod 1 is completely cut off, the length of the arc of the cross-cut 2 is greater than the half circumference of the cross-section of the suction rod 1, but less than the circumference of the cross-section of the suction rod 1; use the sharp point 4 of the oblique cut 3 to pierce the sealing film of the container and reach the bottom of the containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com