Full-automatic pipe bending structure capable of reducing connecting pipe opening deformation quantity during pipe bending

A deformation variable, fully automatic technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of high labor intensity of employees, slow production rhythm, difficult insertion, etc., to reduce labor intensity and improve pipe bending efficiency. , the effect of ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

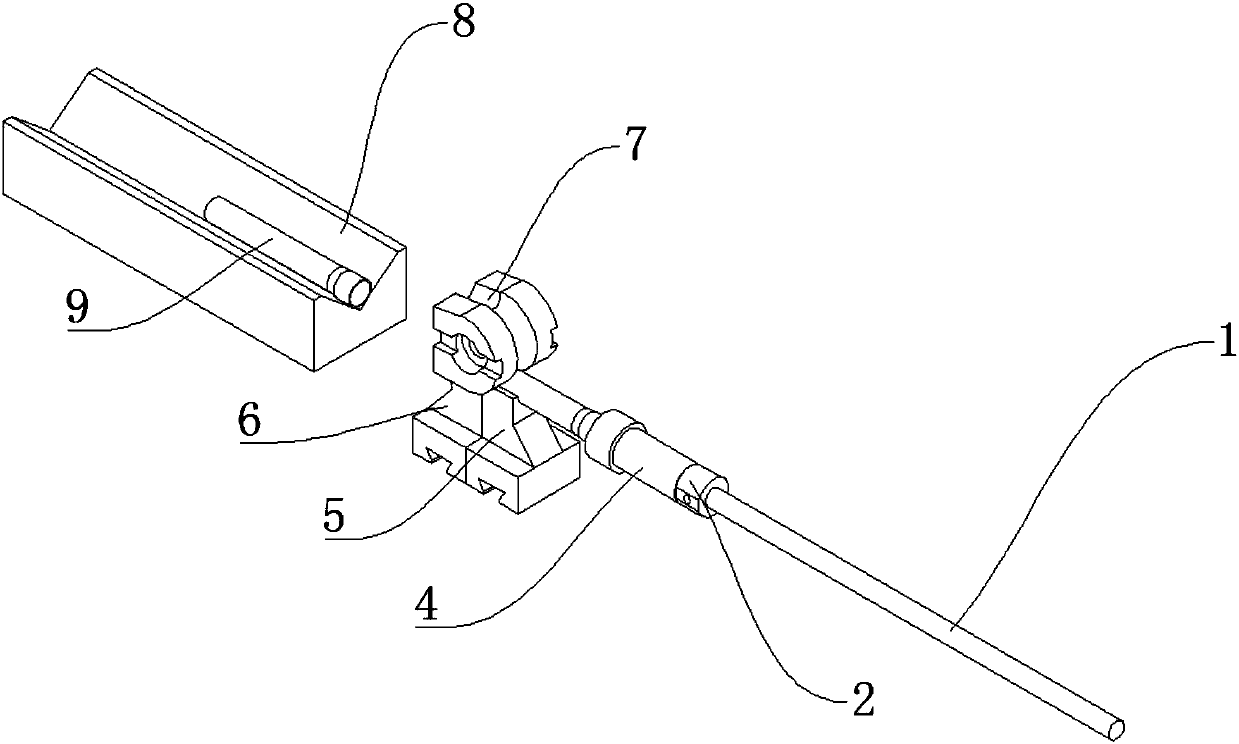

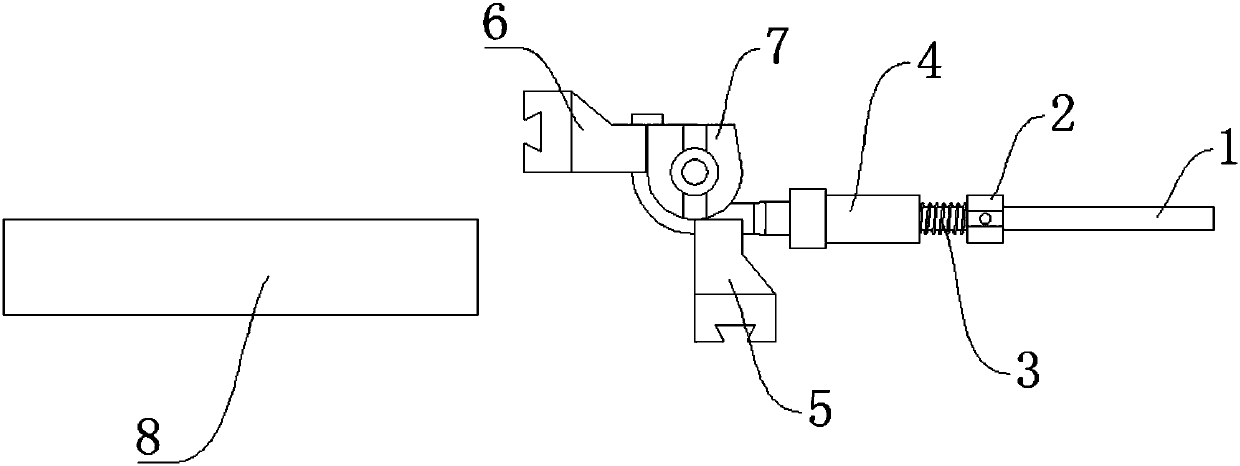

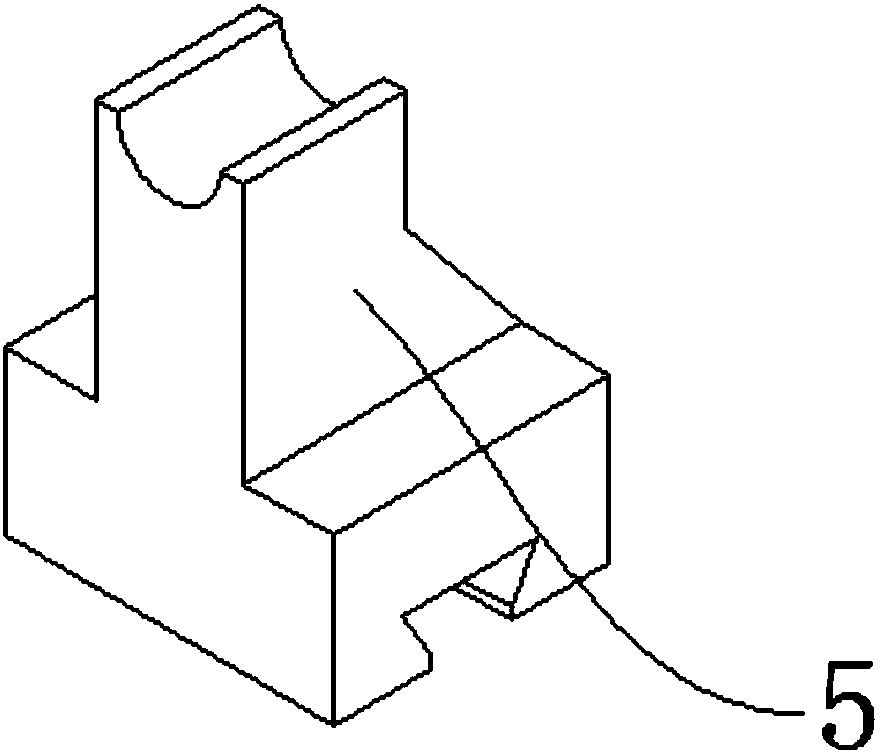

[0023] Such as Figure 1-Figure 6 As shown, a fully automatic pipe bending structure that reduces the deformation of the nozzle when bending the pipe, includes a feeding mechanism 8, a pipe bending round die 7, a connecting pipe 9 is placed on the feeding mechanism 8, and a pipe bending clamp is arranged next to the feeding mechanism 8 Die 6, pipe bend clamping die 6 is provided with bend pipe former 5, the top of pipe bend former 5 is provided with bend pipe round die 7, bend pipe mandrel 1 is arranged beside bend pipe master form 5, bend pipe mandrel 1 A movable bush 4 is arranged on the top, and an elbow positioning block 2 is arranged on the outside of the movable bush 4 , and a compression spring 3 is arranged between the elbow positioning block 2 and the movable bush 4 .

[0024] The upper surface of the feeding mechanism 8 is a V-shaped structure, the connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com