Axlebox built-in compact bogies for metro vehicles

A compact and built-in technology, which is applied in the direction of bogie, axle box installation, and the device for lateral relative movement between the chassis and the bogie. Large and other problems, to achieve the effect of improving the ability to pass through small curves, reducing the stiffness of the shaking head angle, and reducing the radius of gyration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings.

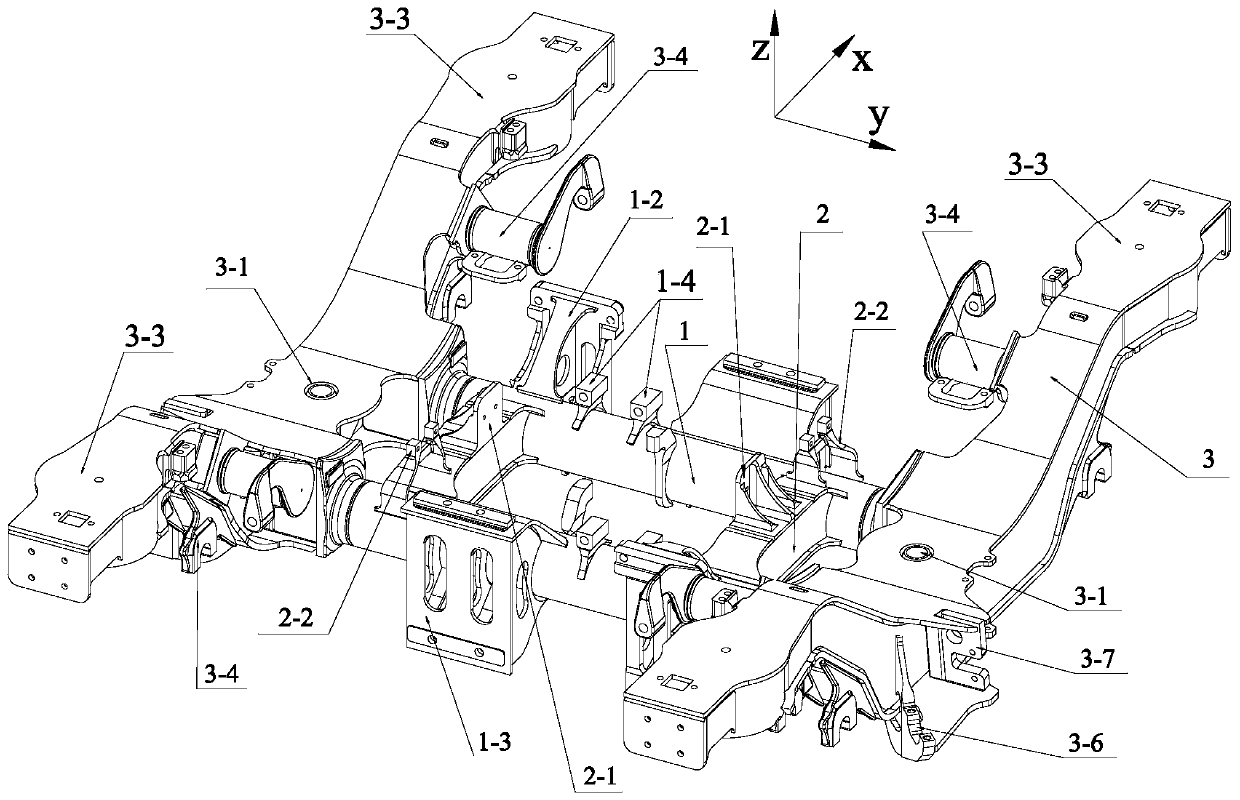

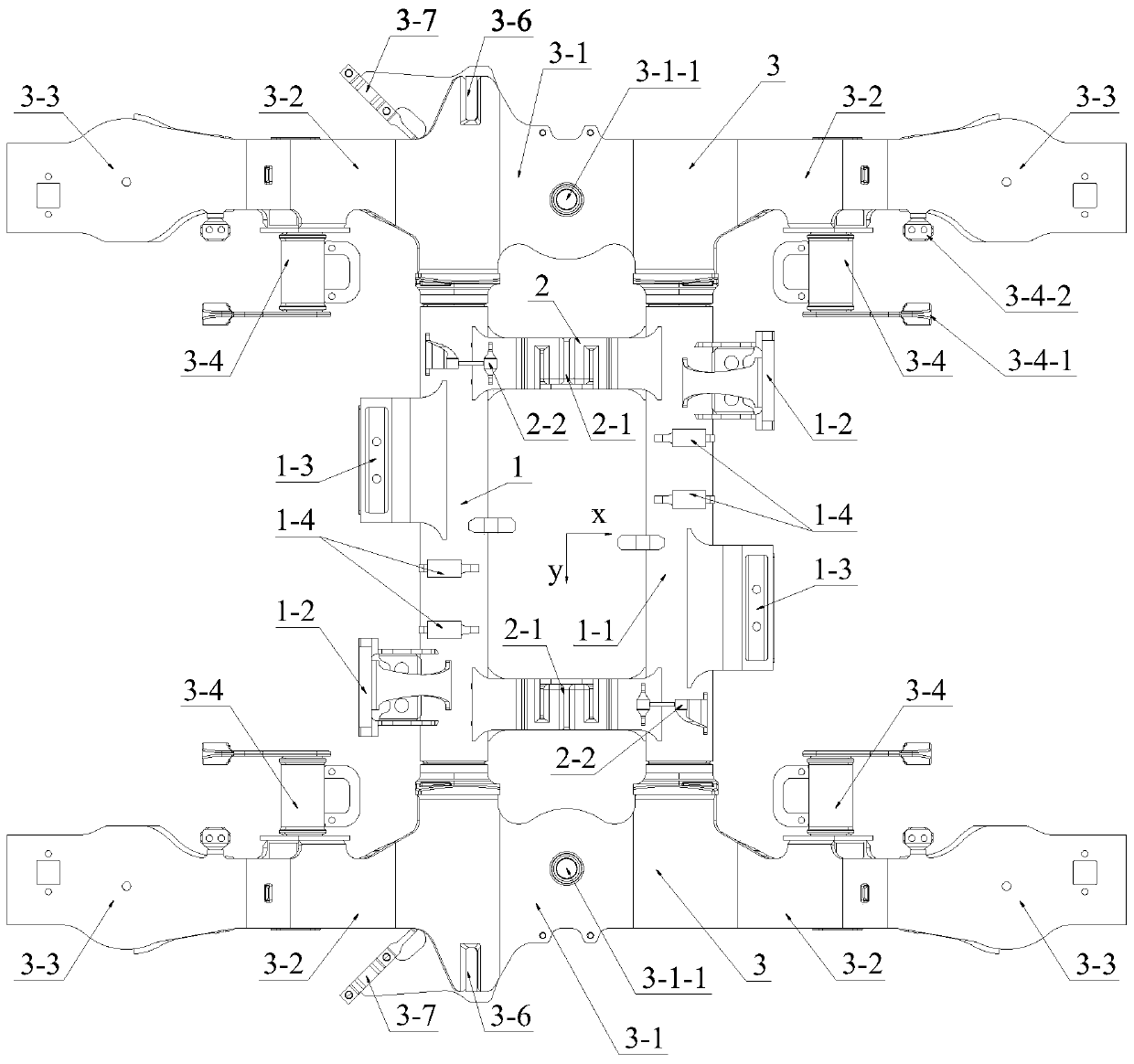

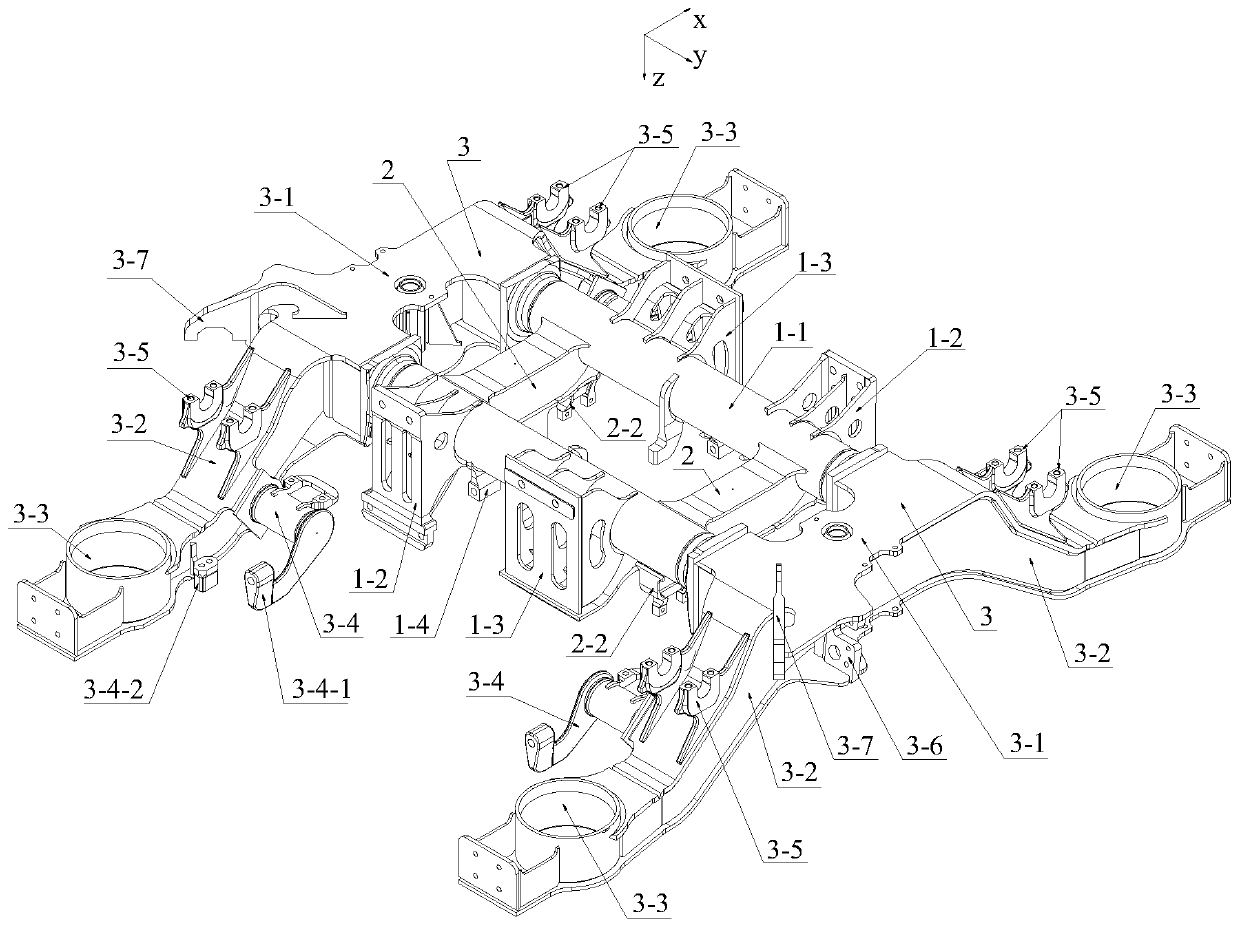

[0067] Such as Figure 4 to Figure 29 As shown, the axle box built-in compact bogie for subway vehicles of the present invention includes two sets of driving devices 14, two sets of braking devices 15 and two sets of wheel set devices 6, compact casting frame, compact secondary suspension system and two sets of wheelset built-in axle box devices 7. The wheel set 6 includes an axle 6-2 and wheels 6-1 symmetrically arranged at its two ends, the driving device 14 includes a traction motor 14-1 and a gear box 14-2, and the braking device 15 includes two groups of wheel set brakes, which adopt Conventional hydraulic shoe brakes.

[0068] The compact casting frame includes a beam unit 4 and two side beam units 5 , the two side beam units 5 are arranged parallel and symmetrically on both sides of the beam unit 4 , and the three are integrally formed by casting pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com