System for treating rust on inner walls of tube parts in batches

A technology for batch processing and parts, applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve the problems of poor rust removal effect and low efficiency, reduce the chance of rust and facilitate replacement , Anti-corrosion and oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

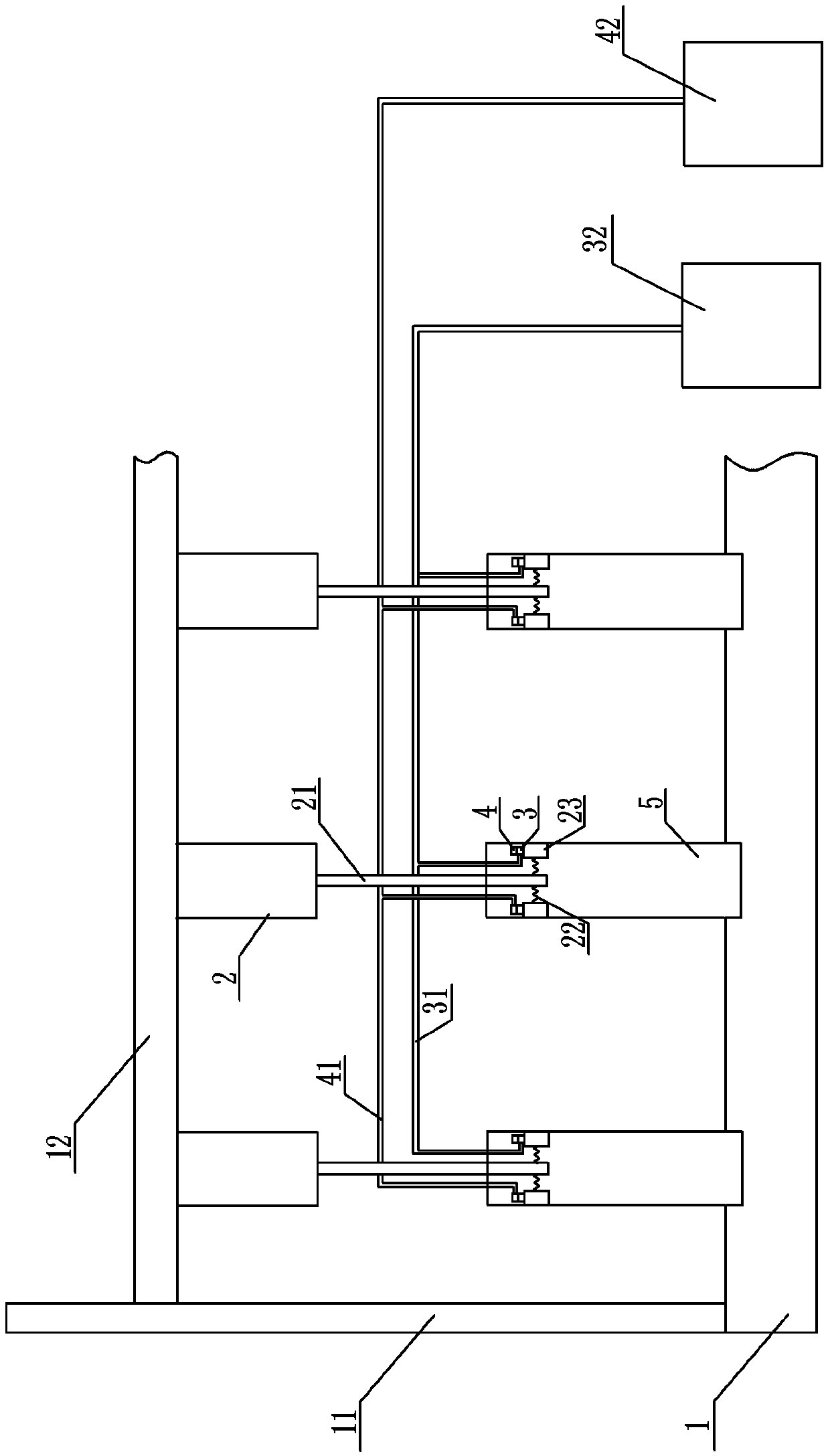

[0025] The reference signs in the accompanying drawings include: frame 1, slide bar 11, fixed bar 12, motor 2, rotating shaft 21, elastic device 22, aluminum block 23, acid spray nozzle 3, infusion tube 31, acid supply device 32. Oxygen nozzle 4, oxygen delivery pipe 41, oxygen supply device 42, pipe body 5.

[0026] The embodiment is basically as attached figure 1 Shown:

[0027] The basic solution provided by the present invention is: a system for batch processing the inner wall rust of pipe parts, including:

[0028] Frame 1, the frame 1 is provided with a base, the base is provided with 20 fixing seats for fixing the pipe body 5, one end of the base is provided with a slide bar 11 vertical to the base, and the top of the base is provided with The fixed rod 12 that moves up and down along the slide rod 11; also includes a cylinder, the piston rod of the cylinder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com