Negative Poisson's specific heat setting device and method for warp-knitted spacer fabric

A technology of warp-knitted spacer fabrics and setting devices, applied in the directions of fabric surface trimming, heating/cooling fabrics, textiles and papermaking, etc., to achieve simple operation, adjustable effect and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

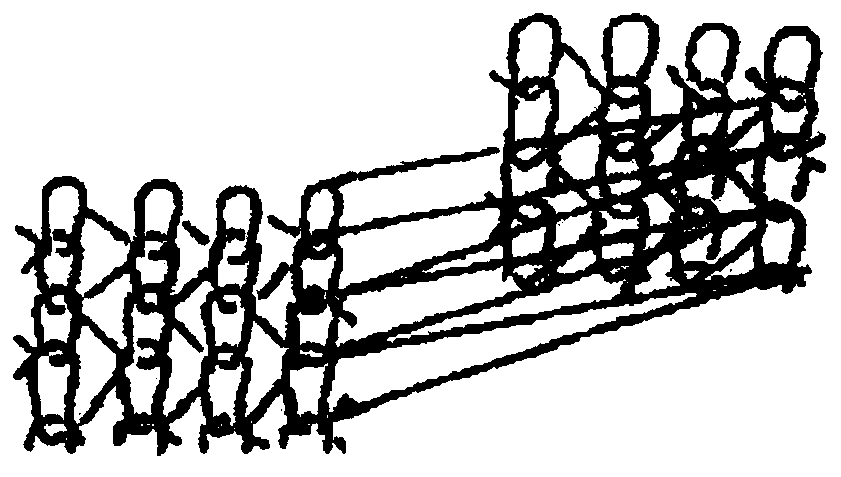

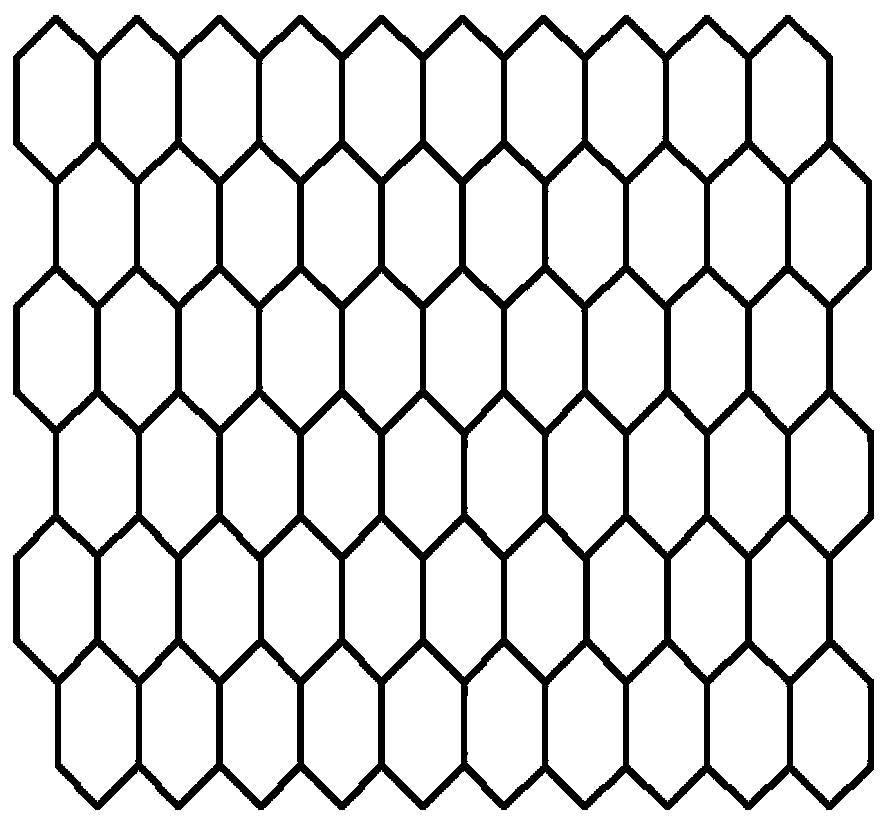

[0026] The warp knitted spacer fabric negative Poisson's ratio heat setting device of embodiment one of the present invention, as Figure 4 As shown, the warp knitted spacer fabric negative Poisson's ratio heat setting device includes a cloth inlet area, a heat setting area and a cloth outlet area. The heat-setting zone includes three pairs of rollers 1 of the same size and a plurality of splints 2, each pair of rollers is gear-shaped and arranged on the same level with the same interval distance, and a plurality of splints 2 are respectively located on each pair Between the rollers, the transmission channel of the warp-knitted spacer fabric is formed, and the warp-knitted spacer fabric enters the vertical interval of each pair of rollers through the splint 2, and the gear engagement of the rollers causes the spacer yarns of the warp-knitted spacer fabric to fall , thus being compressed in the thickness direction, please refer to the specific structure schematic diagram Figu...

Embodiment 2

[0032] The second embodiment provides a method for warp-knitted spacer fabrics having a negative Poisson's ratio. The warp-knitted spacer fabrics are passed into the warp-knitted spacer fabric negative Poisson's ratio heat-setting device as described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com