Novel longitudinal restraint system

A longitudinal and systematic technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of large maintenance workload, easy damage, and inability to install rail expansion adjusters, so as to avoid frequent maintenance and replacement work in the later period. , reasonable structure, novel concept effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

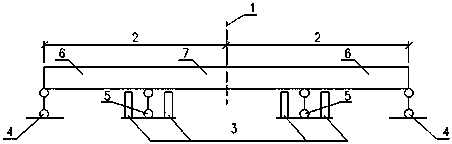

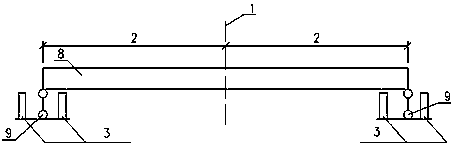

[0024] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0025] Such as figure 1 , 2 As shown, a new type of longitudinal restraint system includes a main girder structure and bridge piers under the main girder structure. Limiting device 3 in the middle of the whole beam.

[0026] In the present invention, the expansion and contraction zero point 1 is set in the middle of the whole beam, which reduces the temperature expansion and contraction of the beam end.

[0027] The main beam structure is a continuous beam or simply supported beam.

[0028] The whole beam adopts movable supports, and the longitudinal movement of the beam body is not restricted. The longitudinal movement of the beam body is limited by the limit device 3 .

[0029] The main beam structure may be a concrete beam or a steel beam.

[0030] When the main girder structure is a continuous beam, the main girder structure includes a main girder side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com