Metal connecting plate of garage door motor

A metal connecting plate and garage door technology, which is applied in the direction of windows/doors, door/window protection devices, building components, etc., can solve the problem that large mounting plates and small mounting plates cannot be adapted to two types of tracks at the same time, increasing production and use Type and cost, etc., to reduce the selection time, expand the applicable area and depth of use, and facilitate the selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

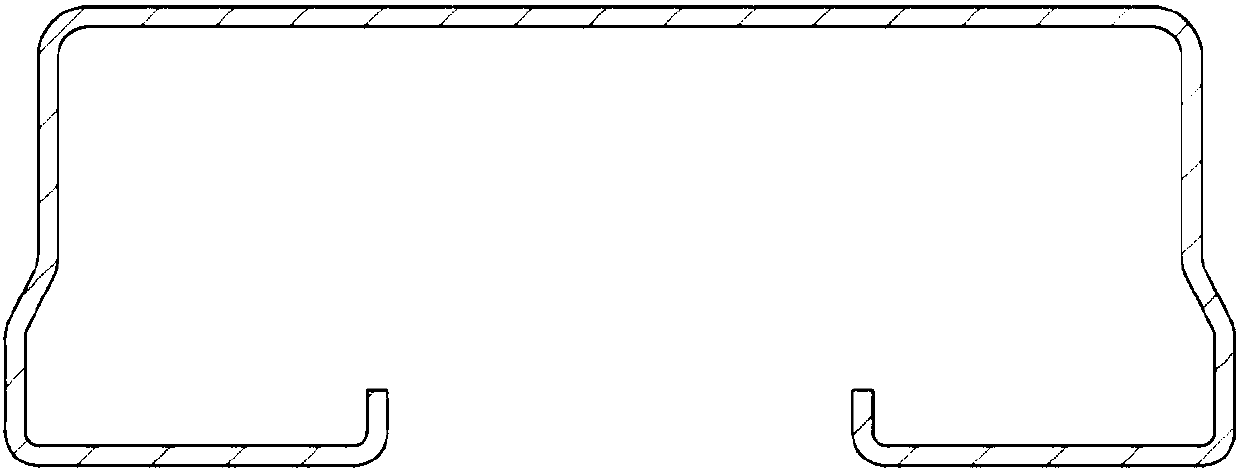

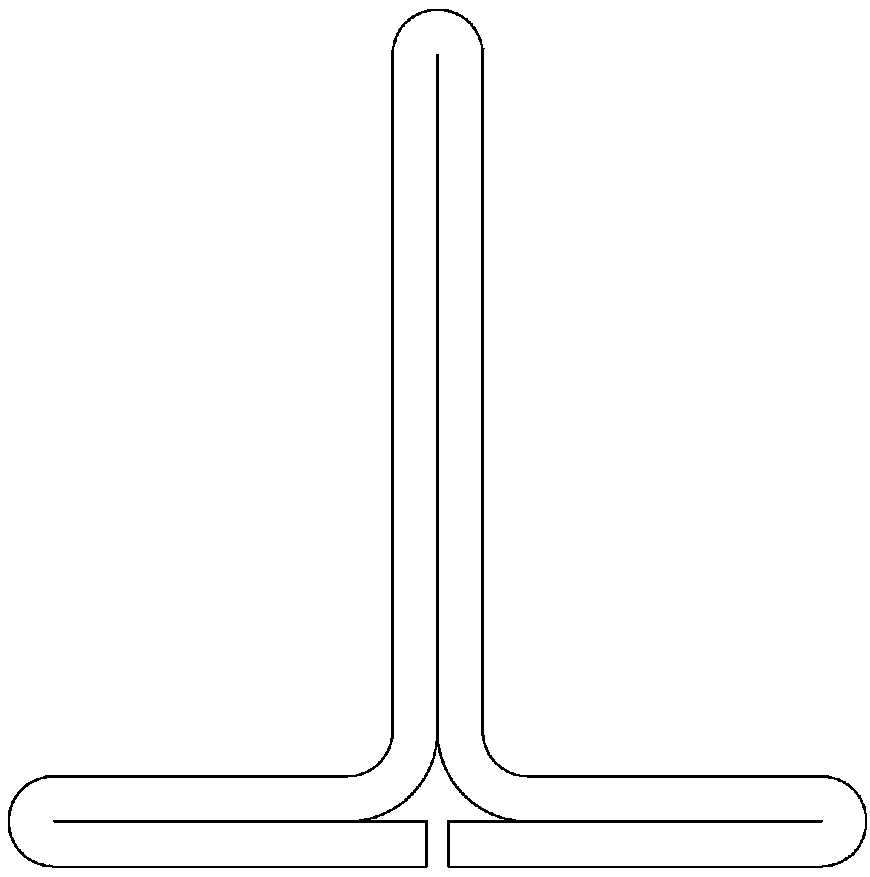

[0035] Embodiment 1, a metal connecting plate for a garage door motor, such as Figure 4 and Figure 5 As shown, it includes a metal bottom plate 1 that is square as a whole. The top of the metal bottom plate 1 is square, and the bottom is arc-shaped, so that the metal bottom plate 1 is easier to align during installation, thereby facilitating the installation of the operator. Both sides of the metal base plate 1 are mounting plates 12 , and the mounting plates 12 are arranged vertically to the metal base plate 1 . The mounting plate 12 is provided with several oblong mounting holes 13, so that the metal bottom plate 1 can be integrally installed in the wall through the cooperation of the mounting plate 12 and the mounting holes 13.

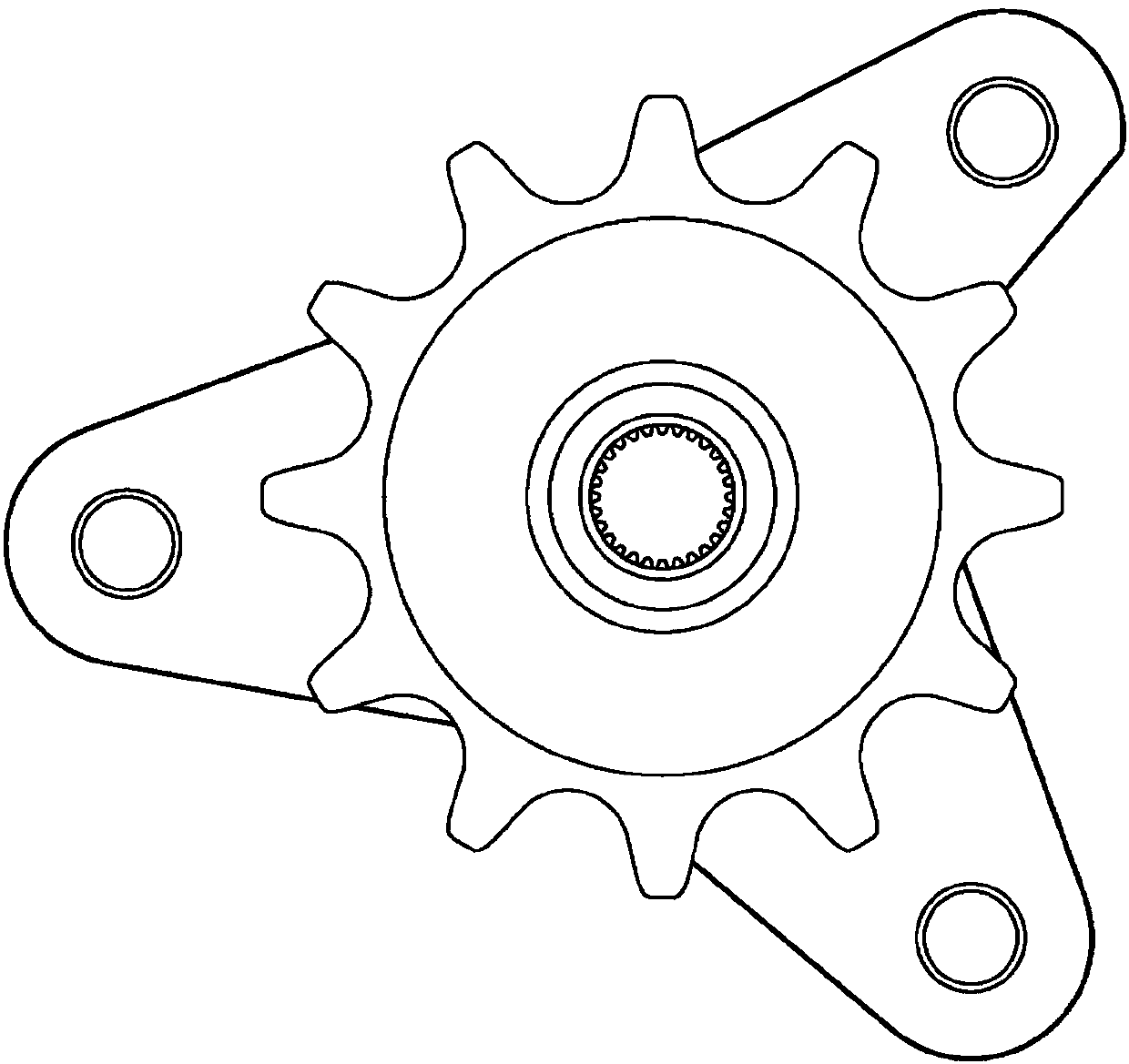

[0036] Such as Figure 4 and Figure 5 As shown, there are two installation grooves in the middle of the metal base plate 1 , the top is the reducer installation groove 3 , and the bottom is the motor installation groove 2 . The motor instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com