A sensing chip clamping and flow control device for a micrometer-scale working distance microscope objective lens

A sensor chip and microscopic objective lens technology, which is applied in the field of photoelectric technology and biomedicine, can solve the problem of short, mostly around tens to hundreds of microns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

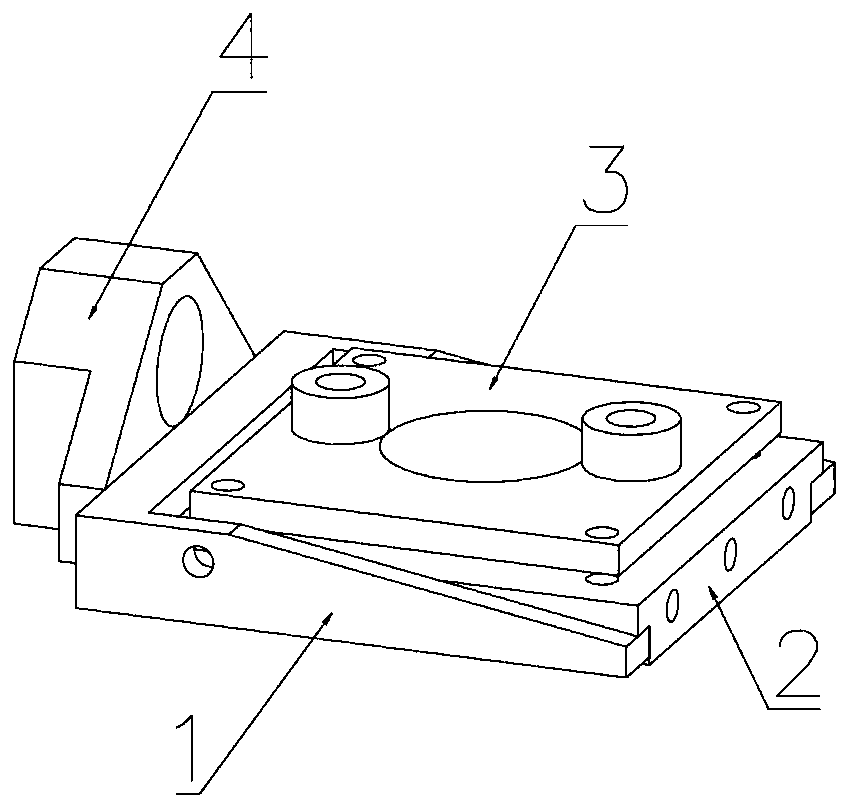

[0032] Implementation Mode 1: Combining Figure 1 to Figure 6 A sensor chip clamping and fluid control device for a micrometer-scale working distance microscope objective lens described in this embodiment, it includes a holder (1), a sensor chip holder (2), a fluid control module (3) ) and three-hole adapter (4) four parts.

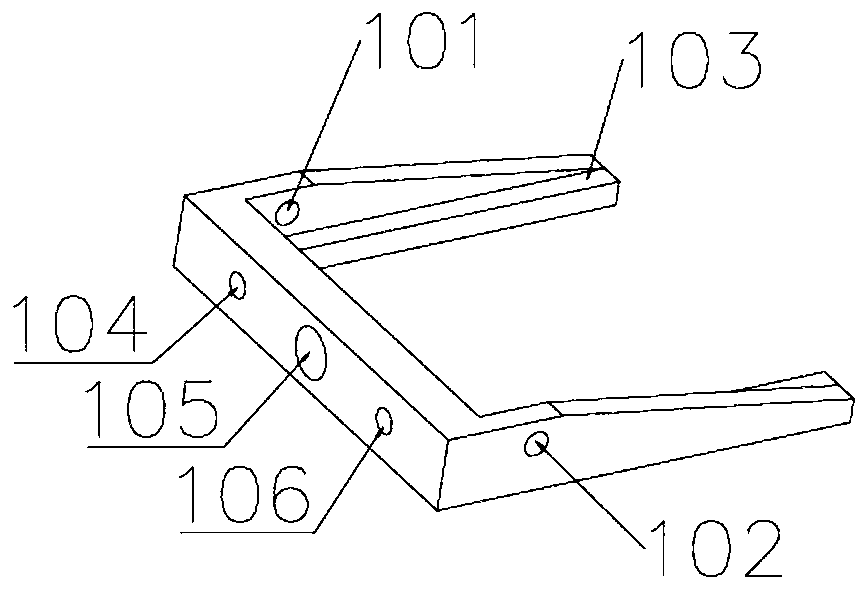

[0033] The pallet fixing frame (1) is processed by cuboid, the middle part of the pallet fixing frame (1) is a groove, and the edge part of the groove has a boss (103); the side of the pallet fixing frame (1) The threaded hole (101) and threaded hole (102) on the top are used to fix the sensor chip holder; the threaded hole (104) and threaded hole (106) on the side of the holder (1) are used to connect with the three-hole adapter The through hole (402) and the through hole (403) are matched.

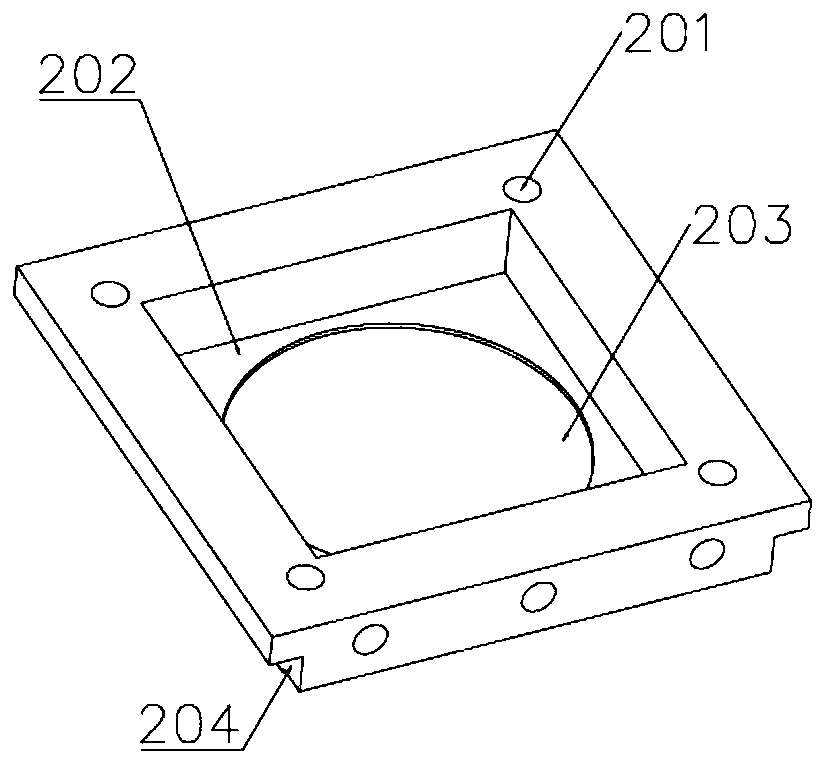

[0034] The four threaded holes (201) on the sensor chip holder (2) are used to cooperate with the four through holes (301) on the fluid control module (3) so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com