Classifiable etching device for printed circuit boards

A technology for printed circuit boards and etching devices, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of incomplete etching and unclassified etching, etc., and achieve the effect of sufficient etching and convenient pick-and-place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

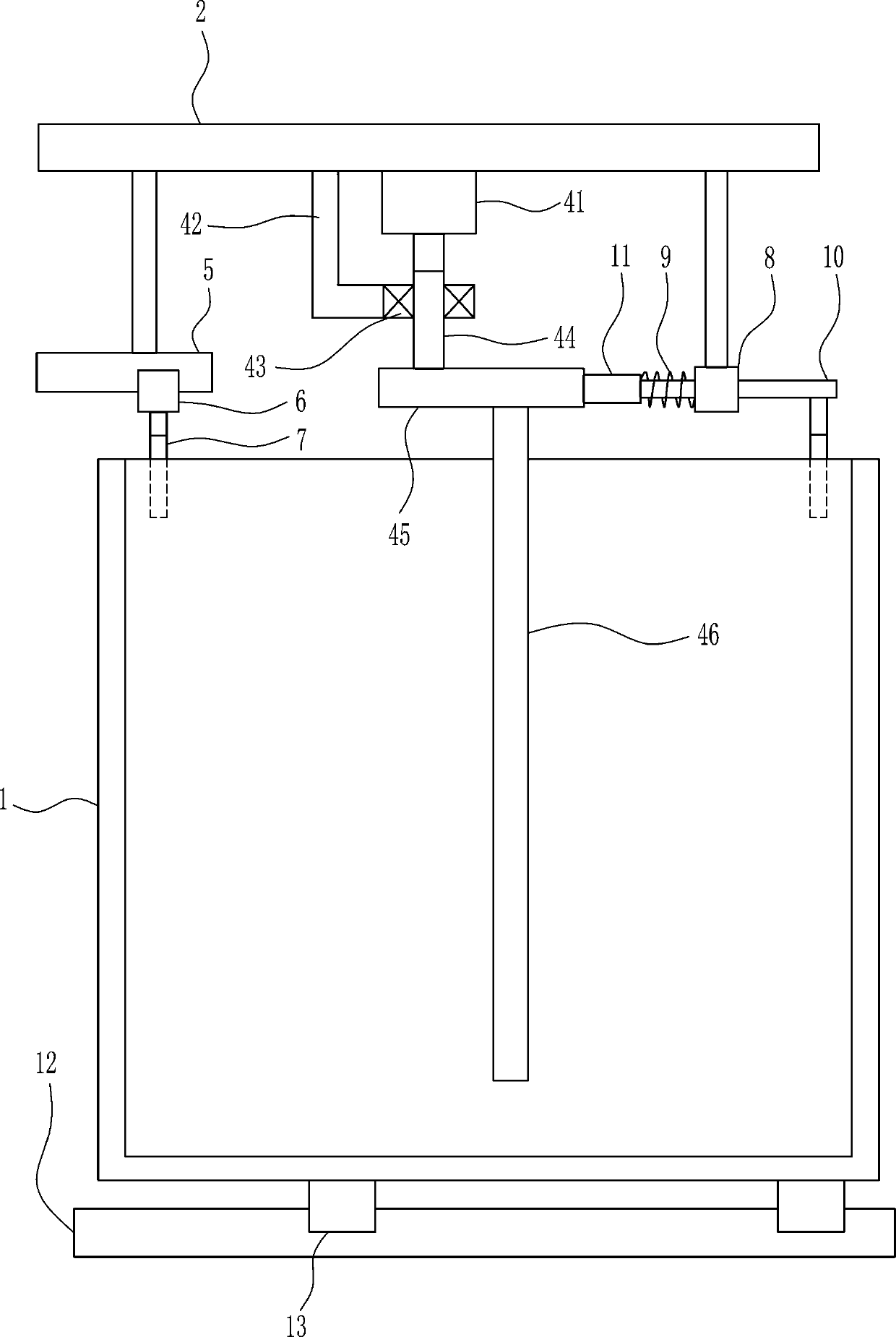

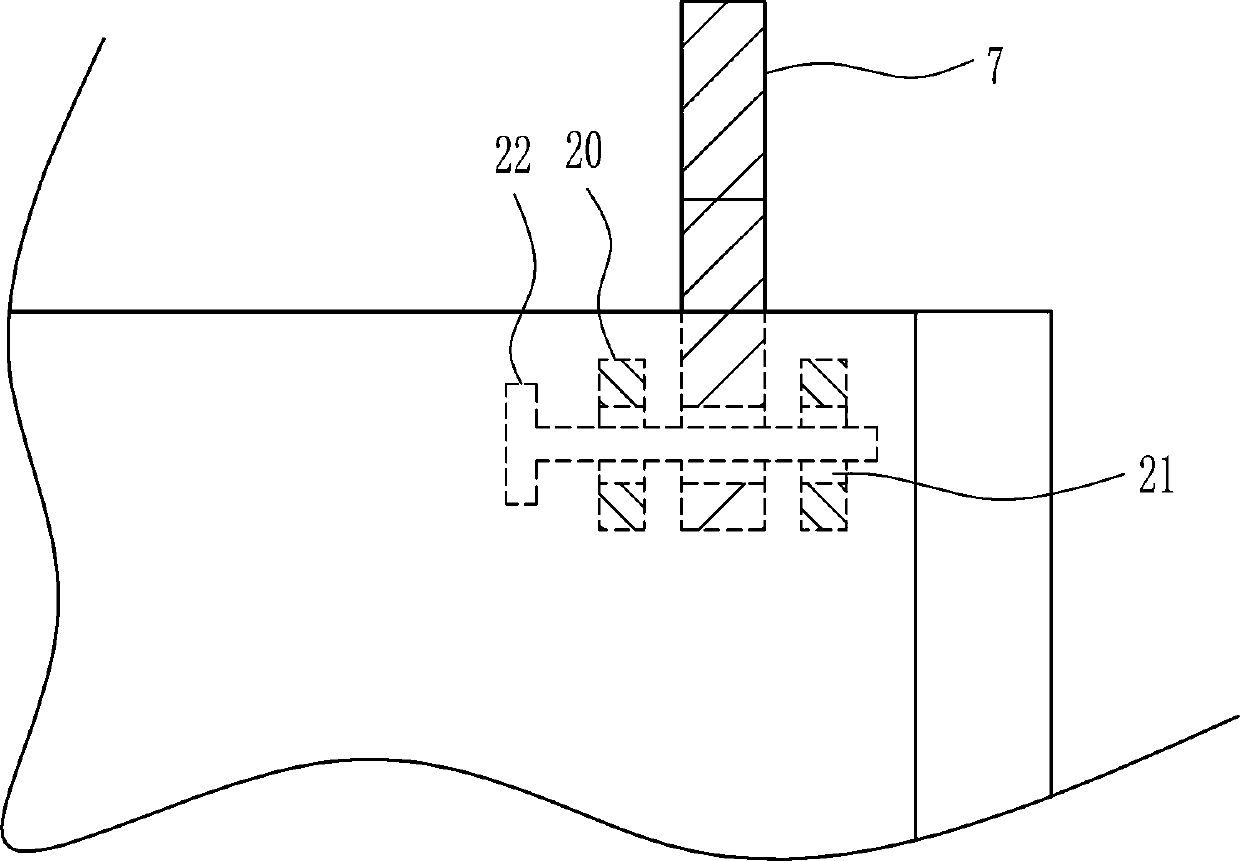

[0035] A sortable etching apparatus for printed circuit boards such as Figure 1-8 As shown, it includes an etching box 1, a top plate 2, a placement mechanism 3, and a stirring mechanism 4. The bottom of the top plate 2 is provided with an etching box 1, and the left and right sides of the etching box 1 are placed with a placement mechanism 3. A stirring mechanism is provided in the middle of the bottom of the top plate 2. 4. The lower part of the stirring mechanism 4 is located in the etching box 1.

Embodiment 2

[0037] A sortable etching apparatus for printed circuit boards such as Figure 1-8 As shown, it includes an etching box 1, a top plate 2, a placement mechanism 3, and a stirring mechanism 4. The bottom of the top plate 2 is provided with an etching box 1, and the left and right sides of the etching box 1 are placed with a placement mechanism 3. A stirring mechanism is provided in the middle of the bottom of the top plate 2. 4. The lower part of the stirring mechanism 4 is located in the etching box 1.

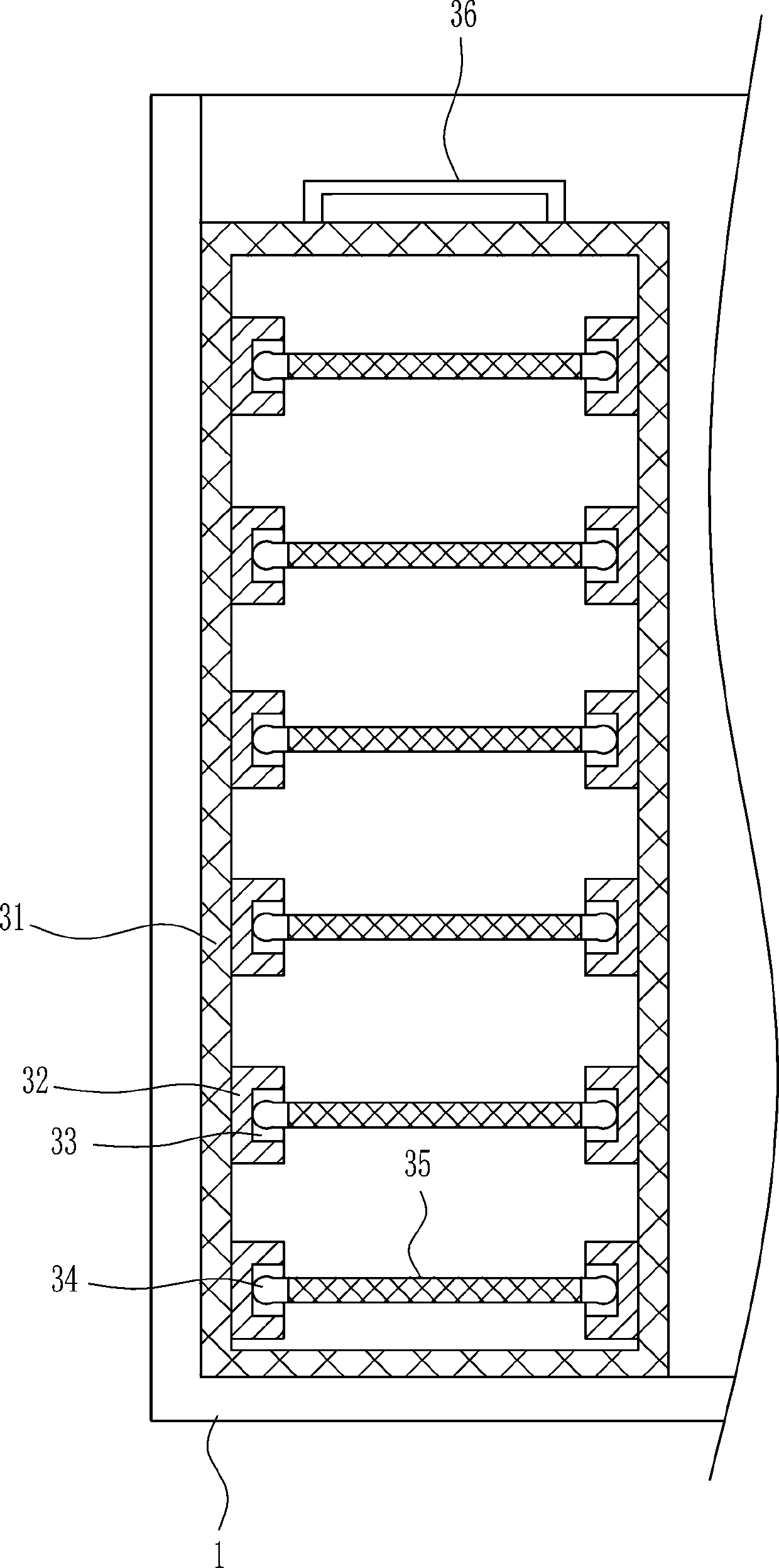

[0038] Placement mechanism 3 includes filter screen frame 31, mounting block 32, moving block 34, the first filter screen 35 and handle 36, and left and right sides are placed with filter screen frame 31 in the etching box 1, the front and rear walls of filter screen frame 31 and etching The front and rear walls of the box 1 are in contact, and the left and right walls of the filter screen frame 31 are evenly connected with installation blocks 32 in a symmetrical manner. The in...

Embodiment 3

[0040] A sortable etching apparatus for printed circuit boards such as Figure 1-8 As shown, it includes an etching box 1, a top plate 2, a placement mechanism 3, and a stirring mechanism 4. The bottom of the top plate 2 is provided with an etching box 1, and the left and right sides of the etching box 1 are placed with a placement mechanism 3. A stirring mechanism is provided in the middle of the bottom of the top plate 2. 4. The lower part of the stirring mechanism 4 is located in the etching box 1.

[0041] Placement mechanism 3 includes filter screen frame 31, mounting block 32, moving block 34, the first filter screen 35 and handle 36, and left and right sides are placed with filter screen frame 31 in the etching box 1, the front and rear walls of filter screen frame 31 and etching The front and rear walls of the box 1 are in contact, and the left and right walls of the filter screen frame 31 are evenly connected with installation blocks 32 in a symmetrical manner. The in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap