Self-positioning waste PCB milling cutter handle recovering and cutting device and method

A milling cutter handle, PCB board technology, applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problem of easy wear and tear of the blade part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

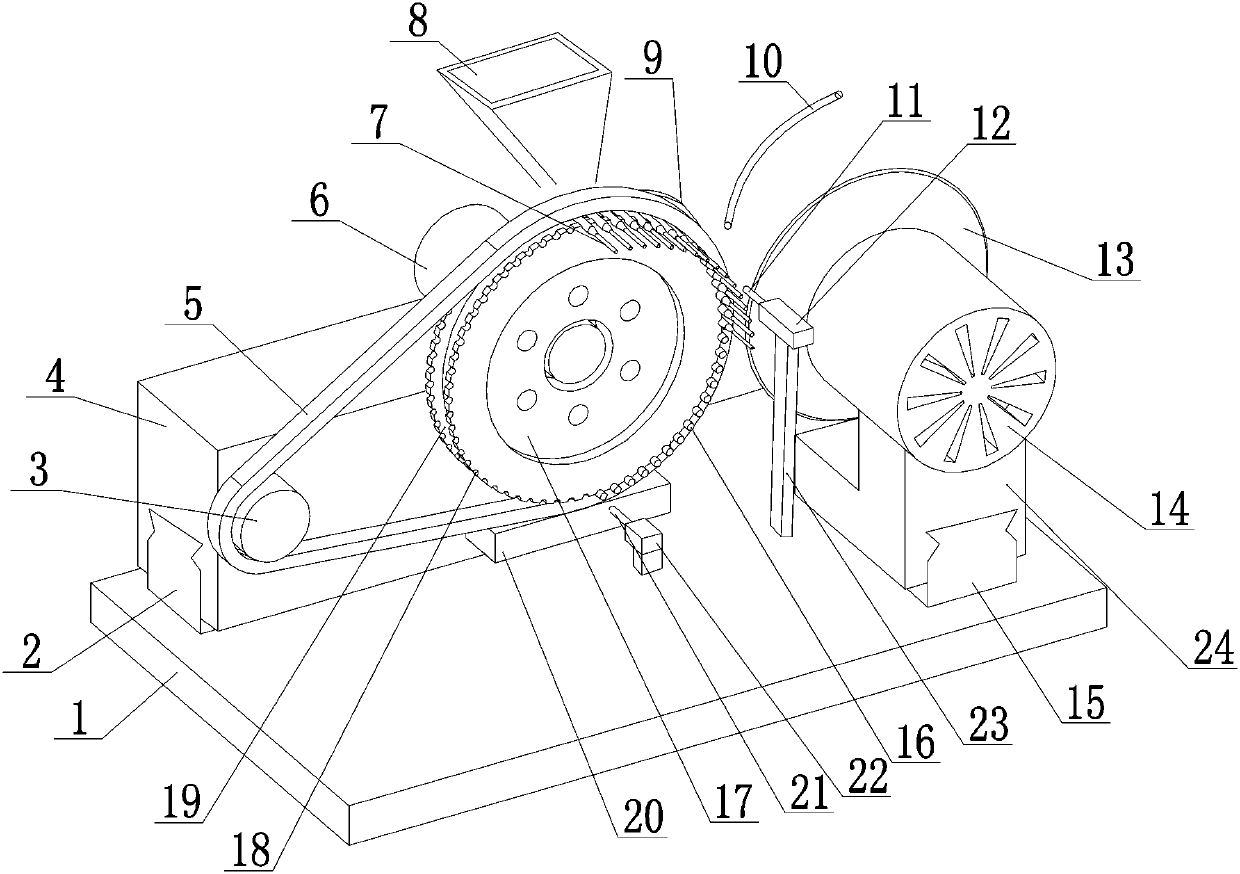

[0037] see figure 1 , self-positioning waste PCB board milling cutter shank recycling cutting equipment, which includes a base 1, a first slide rail 2 and a second slide rail 15 are fixed on the base 1, and a sliding fit is installed on the first slide rail 2 The first sliding seat 4, the first sliding seat 4 is equipped with a clamping device for clamping and rotating the waste milling cutter; the second slide rail 15 is slidably fitted with a device for cutting the bar cutting device; the top of the clamping device is provided with a discharge funnel 8; the side of the clamping device is equipped with a centering mechanism for positioning and aligning the waste milling cutter; the lower side of the clamping device is provided with a The unloading mechanism for unloading the milling cutter bar; the bottom end of the clamping device is located at the position of the unloading mechanism and is provided with a collection box 20 . Due to the short length of the waste milling cut...

Embodiment 2

[0049] A method for cutting and recycling waste milling cutters by any self-positioning waste PCB board milling cutter shank recovery and cutting equipment, which includes the following steps:

[0050] Step1: Place the waste milling cutter 7 bars neatly inside the discharge hopper 8;

[0051] Step2: Adjust the position of the first sliding seat 4 and the motor support 24 on the first slide rail 2 and the second slide rail 15, so as to ensure that the cutting saw blade 13 of the cutting equipment can smoothly cut off the waste milling cutter 7;

[0052] Step3: Start the rotating motor 6 of the clamping device, the rotating motor 6 will drive the clamping disc 17 to rotate, and the waste milling cutter 7 located on the positioning groove 18 will be driven to rotate through the clamping disc 17;

[0053] Step4: The fastening belt 5 of the tool handle fixing mechanism fastens the waste milling cutter 7 on the positioning groove 18, and the chucking disc 17 continues to rotate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com