Method for friction stir welding of high-strength aluminum alloy

A friction stir welding and aluminum alloy technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult to accurately control the heating and cooling process, inability to apply large structural parts, and complicated processing processes. The effect is stable and reliable, saving processing time and reducing the effect of the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

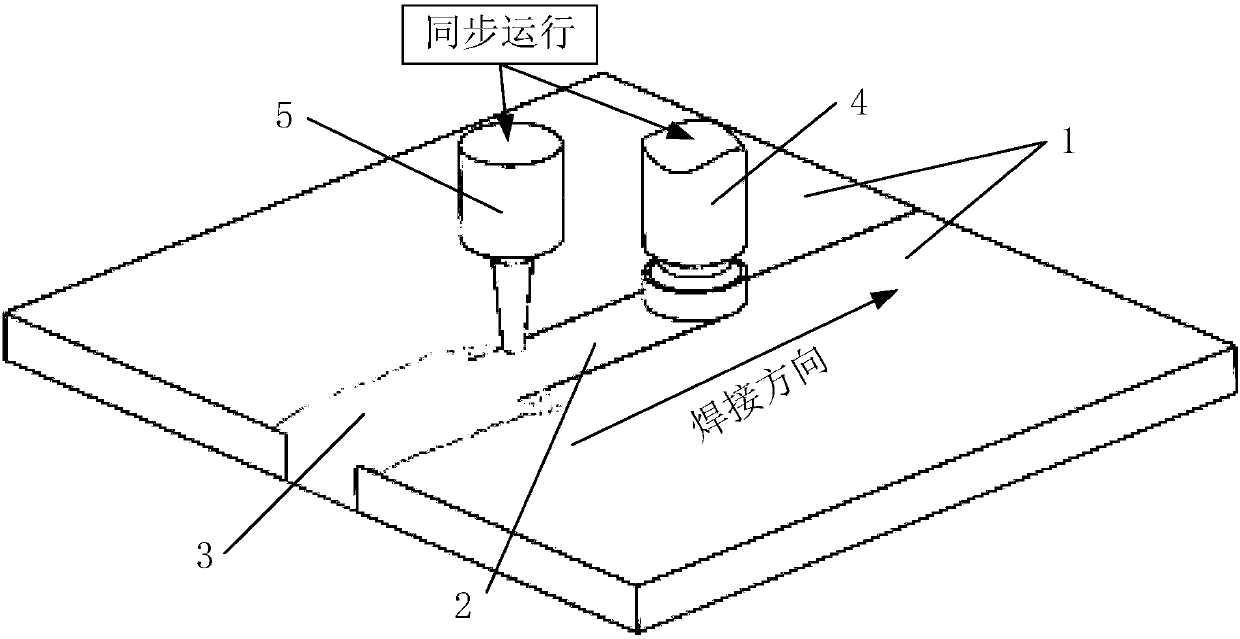

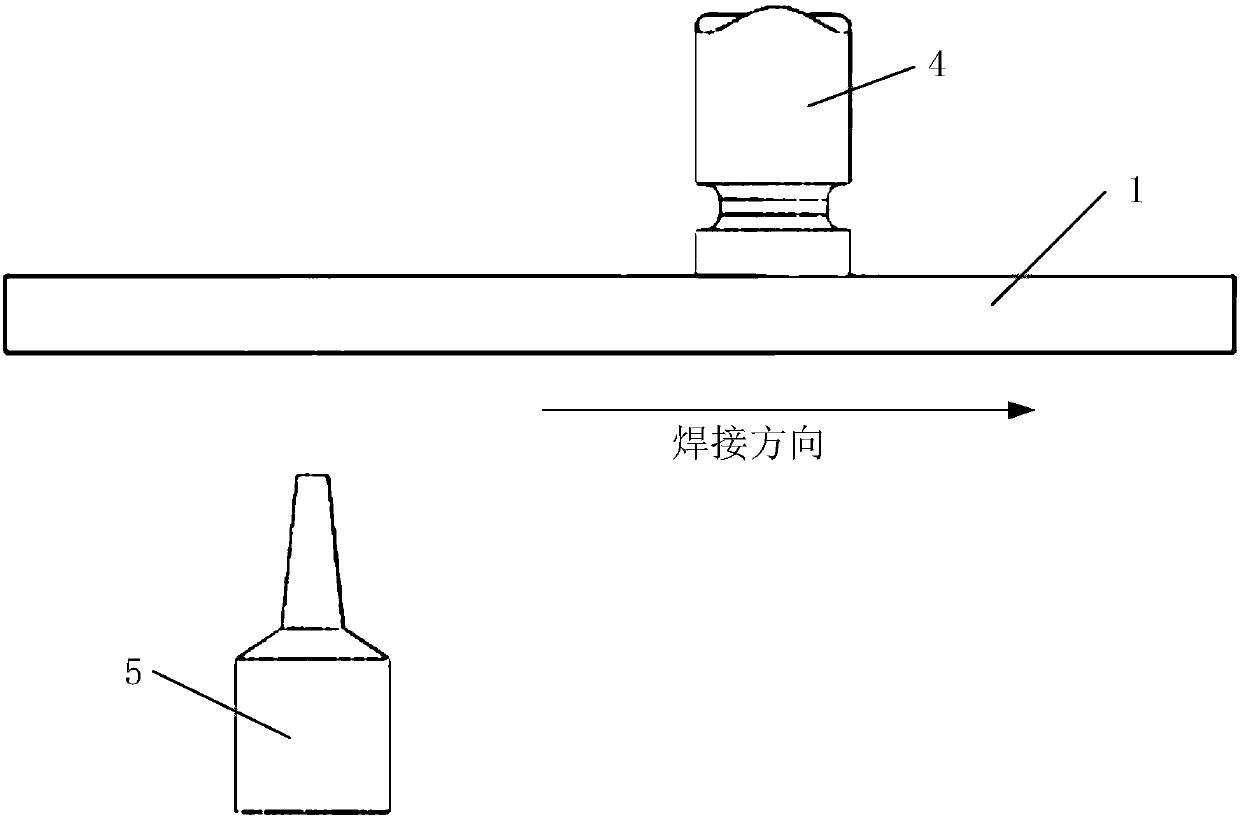

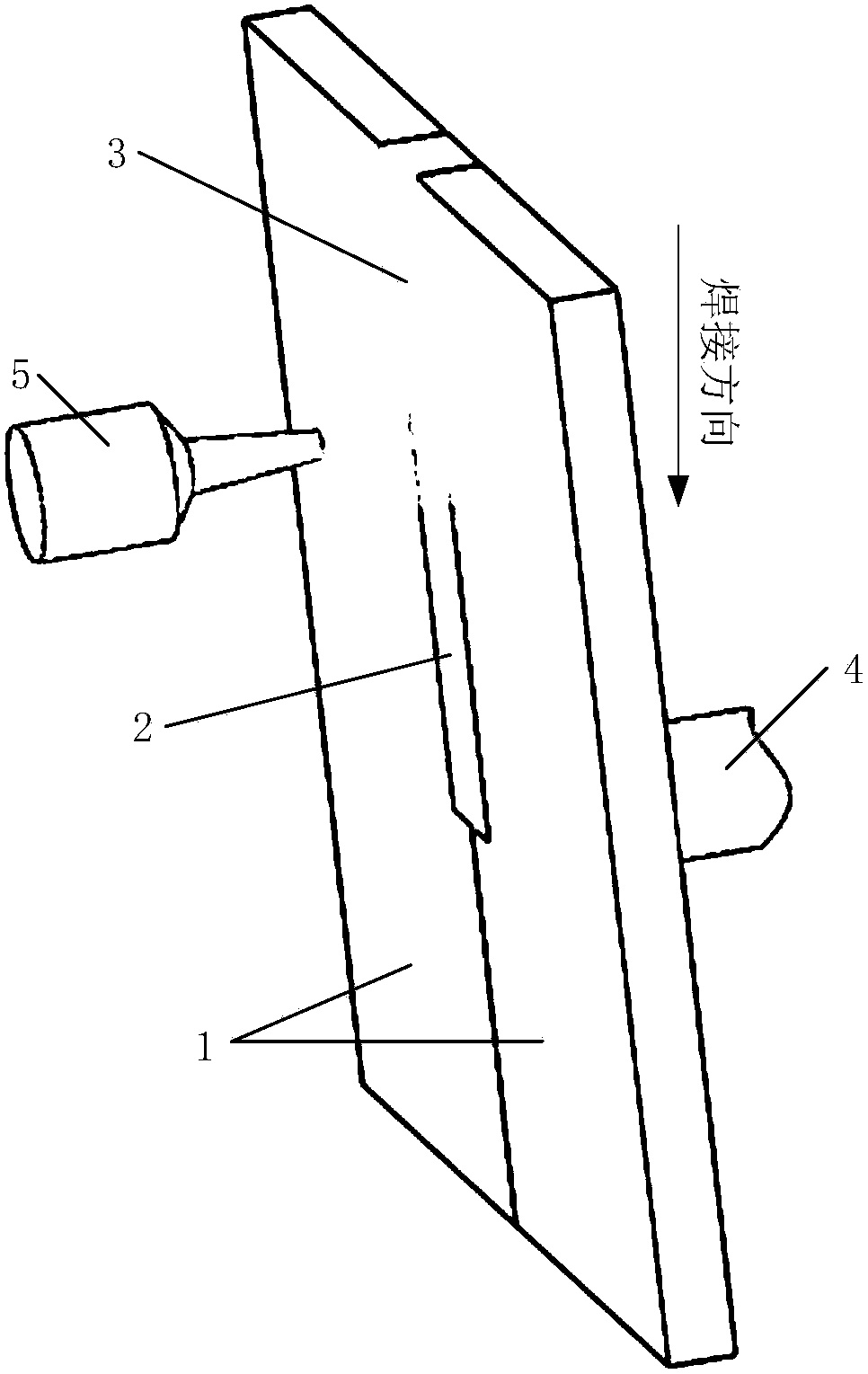

[0030] Such as figure 1 As shown, a high-strength aluminum alloy friction stir welding method is used to process the 6mm thick 2219 high-strength aluminum alloy welded joints, which specifically includes: 4 pairs of high-strength aluminum alloy parts to be welded in the friction stir welding equipment 4 While the friction stir welding is being performed, the spray gun 5 of the cold spray equipment performs cold spray treatment on the welded part 2 synchronously, thereby forming a cold spray coating 3 at the welded joint of high-strength aluminum alloy.

[0031] Specifically, the stirring head 4 of the friction stir welding equipment and the spraying gun 5 of the cold spraying equipment are located on the same side of the high-strength aluminum alloy to be welded 1, the two are fixed together and the spraying gun 5 of the cold spraying equipment is located at the temperature behind the stirring head 4 The field is 400°C, and the two move synchronously, realizing the cold spray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com