Gas-liquid-solid three-phase abrasive flow polishing tool based on cavitation effect

A polishing tool and cavitation effect technology, applied in grinding/polishing equipment, manufacturing tools, grinding machines, etc., can solve the problems of low three-phase abrasive flow processing efficiency and uneven polishing removal, and increase bubble collapse the probability of, ensuring uniformity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

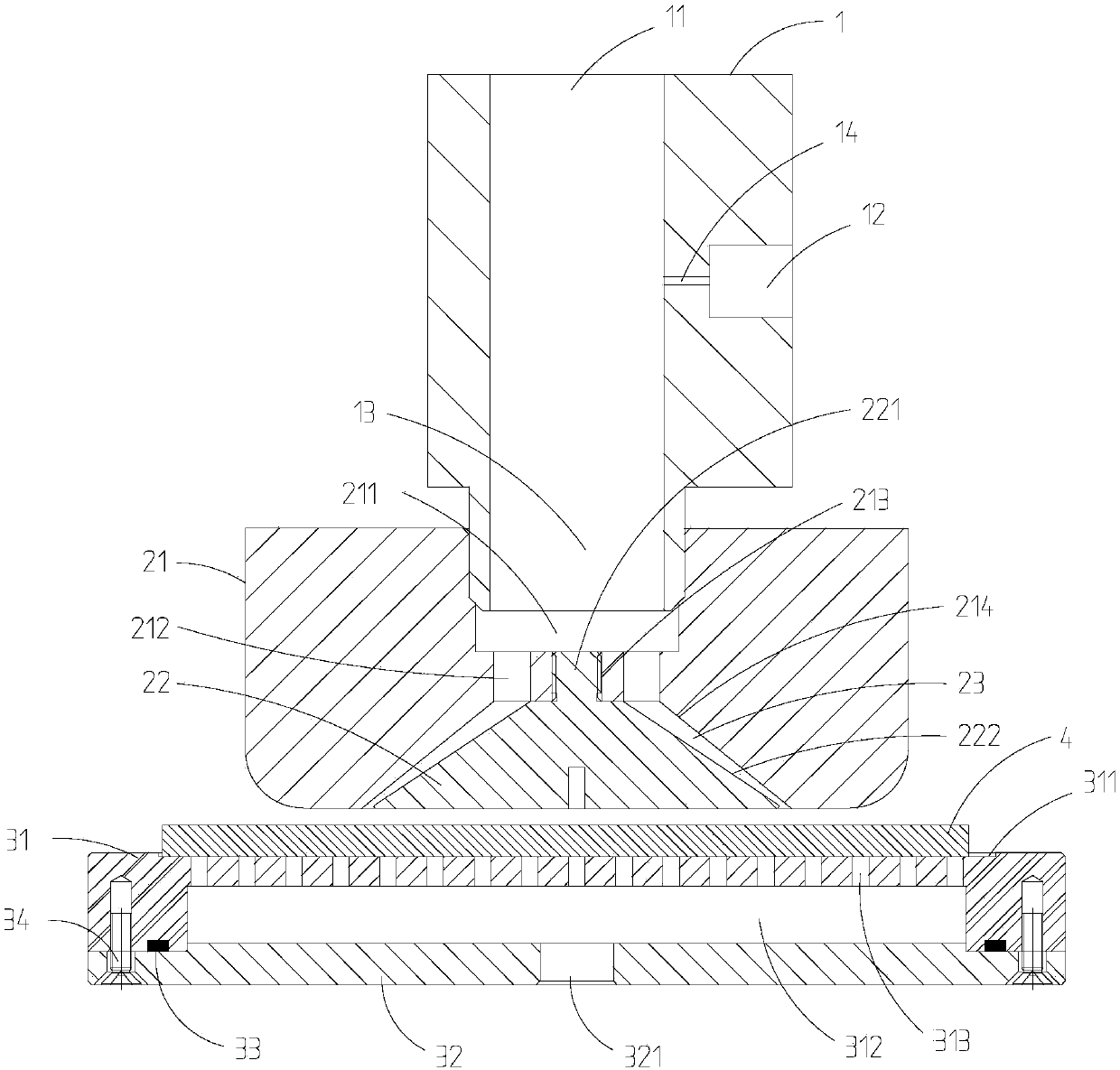

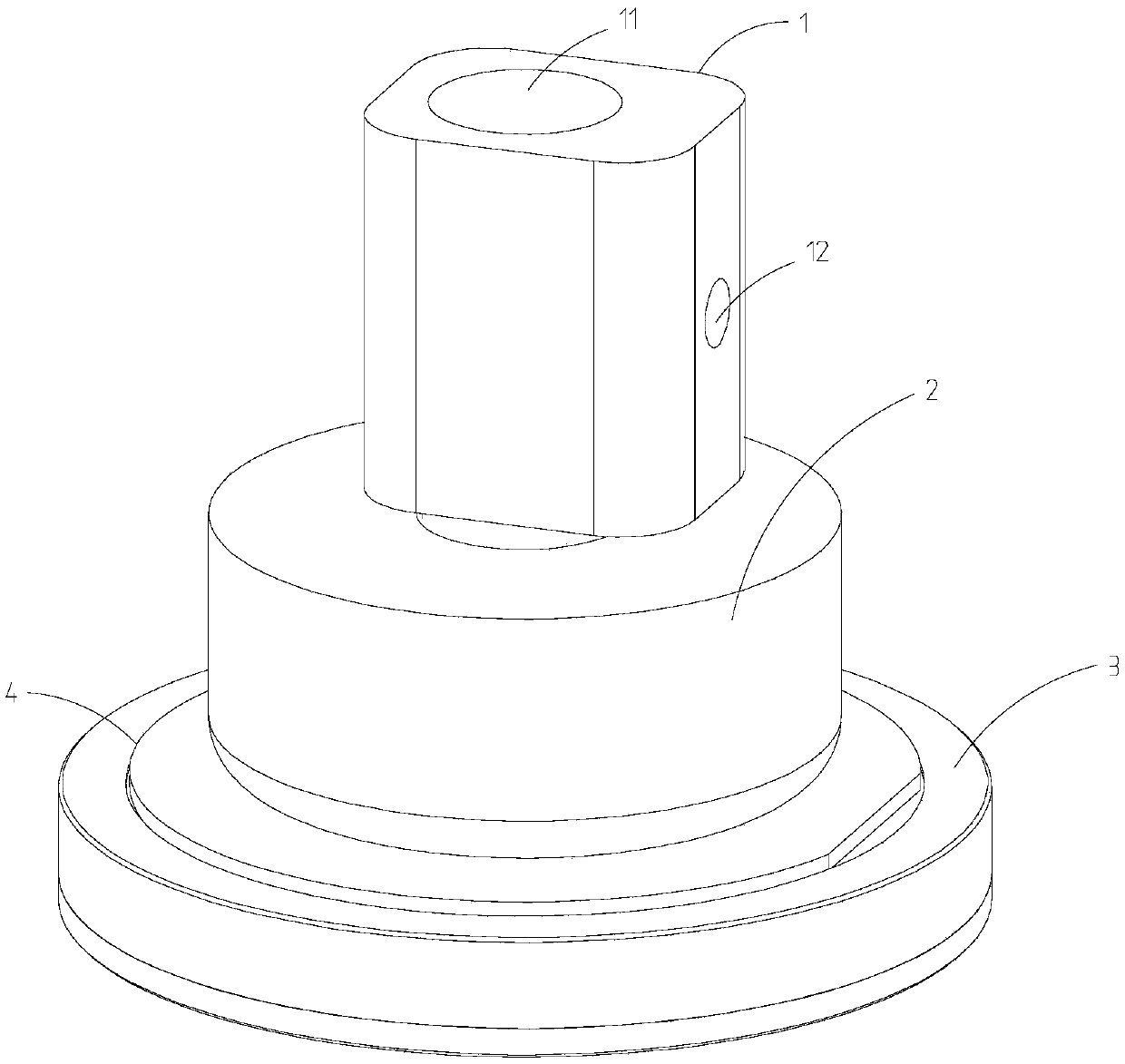

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a gas-liquid-solid three-phase abrasive flow polishing tool based on the cavitation effect includes a gas-liquid-solid mixing device 1, a cavitation polishing tool 2 and a workpiece fixing platform 3, and the workpiece 4 to be processed is installed on the workpiece On the fixed platform 3; the bottom surface of the cavitation polishing tool 2 is a plane, the cavitation polishing tool 2 is placed above the workpiece 4 and the bottom surface of the cavitation polishing tool 2 is parallel to the upper surface of the workpiece 4, the gas-liquid-solid mixing device 1 Connect the cavitation polishing tool 2 and flow the mixed gas-liquid-solid three-phase abrasive grain into the cavitation polishing tool 2 .

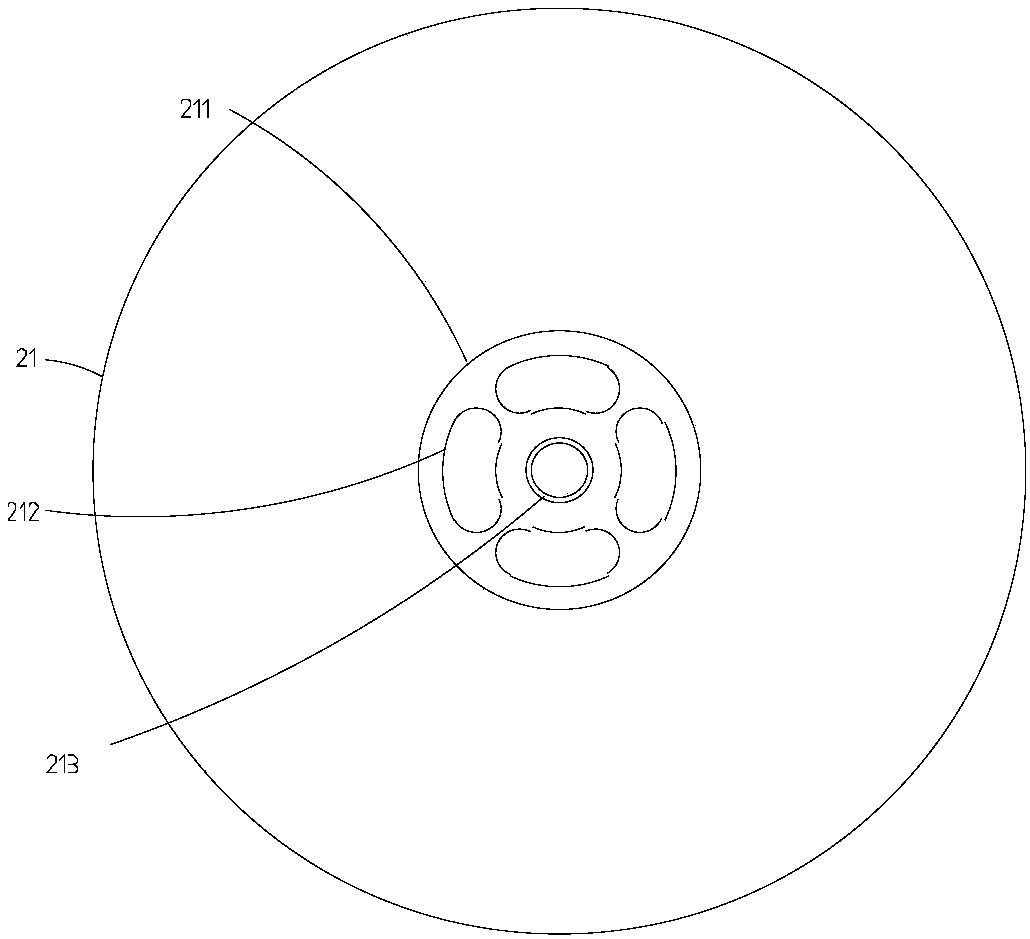

[0031] The cavitation polishing tool 2 includes an outer constraint body 21 and an inner constraint body 22, and the outer constraint body 21 is provided with a flow channel inlet 211, an internal flow c...

Embodiment 2

[0039] The scheme of this embodiment is basically the same as that of Embodiment 1, the difference is that the upper surface of the workpiece 4 to be processed is a curved surface with a fixed curvature, and the lower surface of the inner constraint body 22 on the cavitation polishing tool 2 is a curved surface with a fixed curvature. 2. The shortest distance between any point on the lower surface of the upper internal constraint body 22 and the upper surface of the workpiece 4 is equal, that is, the upper surface of the workpiece 4 is parallel to the lower surface of the inner constraint body 22 in the cavitation polishing tool 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com