Gas-liquid-solid three-phase abrasive flow plane polishing system based on cavitation effect

A technology of cavitation effect and abrasive flow, which is applied in the direction of used abrasive processing devices, abrasives, abrasive jet machine tools, etc., can solve the problem of three-phase abrasive flow polishing efficiency improvement effect is not obvious, three-phase abrasive flow processing Low efficiency, uneven removal amount on the processed surface, etc., to achieve the effect of improving polishing efficiency, high material removal rate, and increasing the probability of bubble collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing:

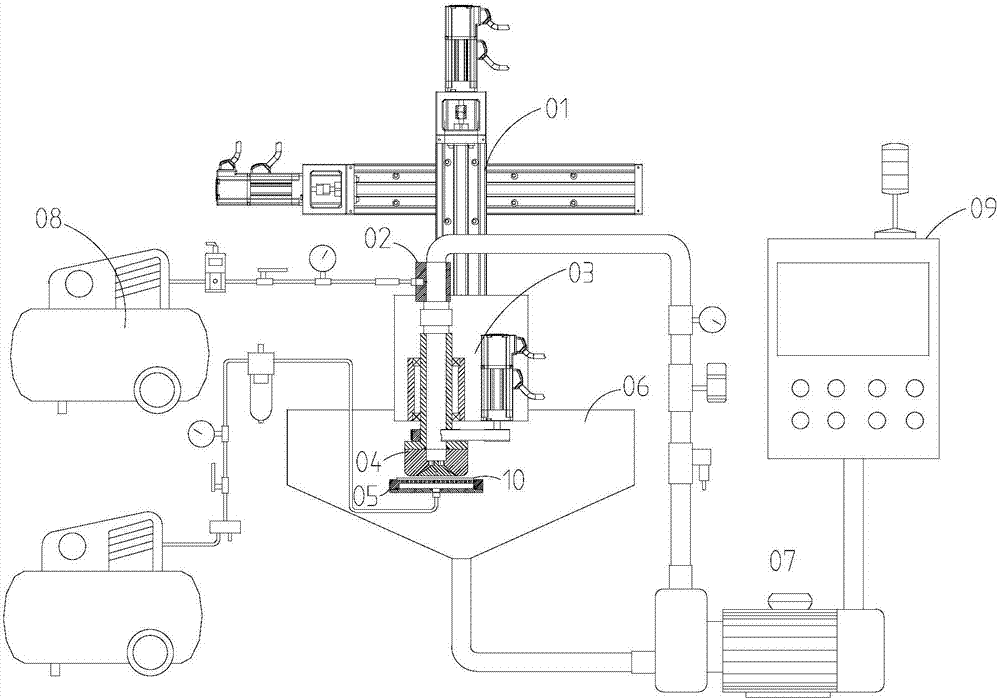

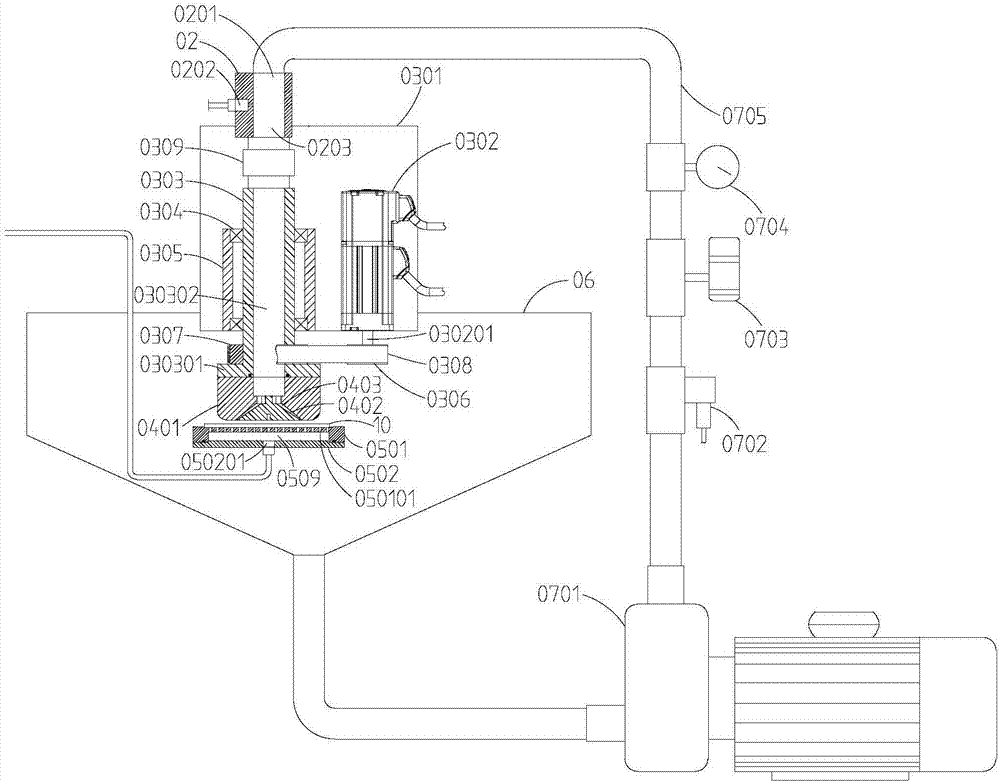

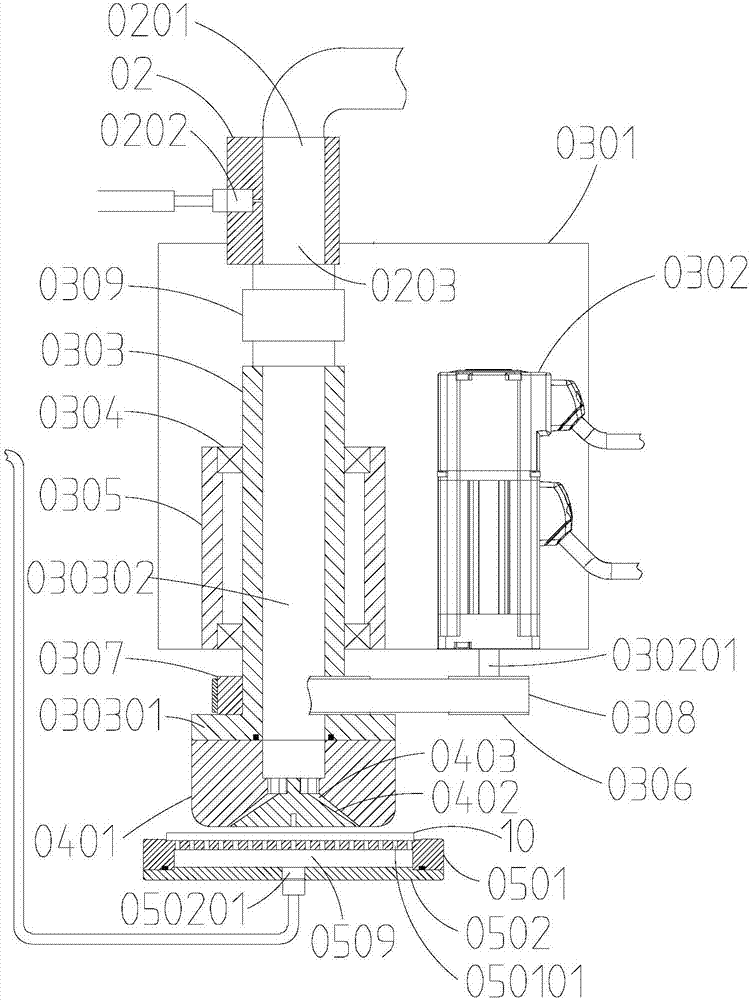

[0043] Such as Figure 1~6 As shown, a gas-liquid-solid three-phase abrasive flow planar polishing system based on the cavitation effect includes a two-degree-of-freedom moving device 01, a gas-liquid-solid mixing device 02, a rotating drive device 03, a cavitation polishing tool 04, and a workpiece device Clamping device 05, workpiece processing pool 06, abrasive particle flow circulation device 07, high-pressure gas injection device 08 and console 09, the rotary drive device 03 is installed on the two-degree-of-freedom mobile device 01, and when the two-degree-of-freedom mobile device 01 moves Drive the rotary drive device 03 to move linearly in both horizontal and vertical directions; the gas-liquid-solid mixing device 02 is installed on the mounting base 0301 of the rotary drive device 03, and the rotating end of the rotary drive device 03 is connected to the cavitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com