Grinding equipment for honeycomb type fireproof heat-preservation material and grinding method of grinding equipment

A fire-proof and heat-preserving, honeycomb-type technology, which is applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of poor flame retardancy and low fire protection level, and achieve overall structural stability, low energy consumption, and heat conduction The effect of a small coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

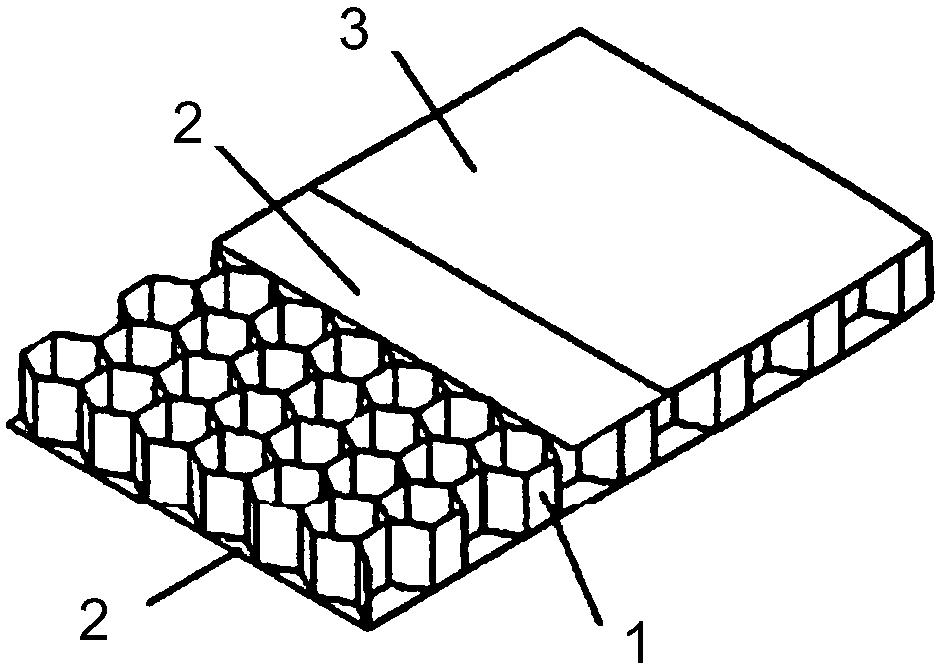

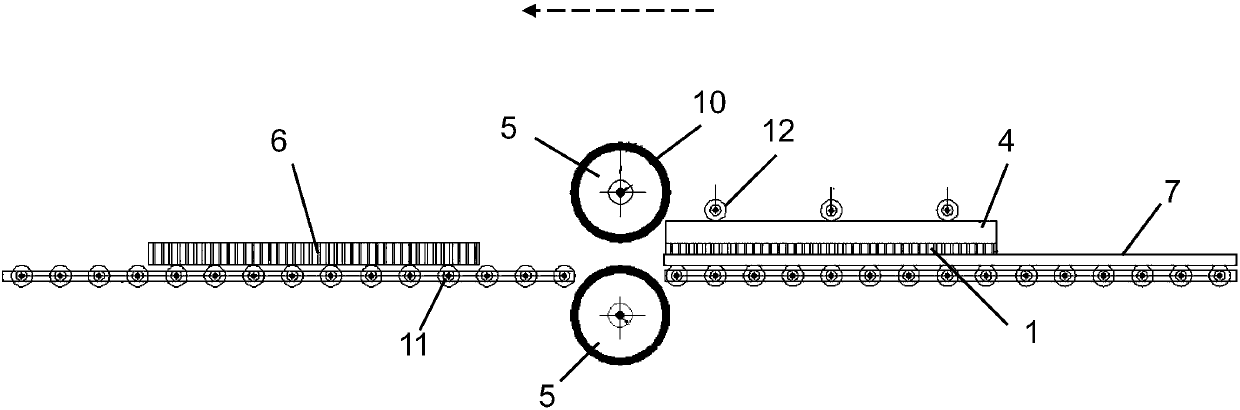

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] Please combine Figure 2 to Figure 5 As shown, the rolling equipment of the honeycomb fireproof and thermal insulation material of the present invention includes several pairs of rolling rollers 5 arranged up and down, and a conveying device 11 arranged on the front and rear sides of the rolling rollers 5 .

[0033] Among them, above the conveying device 11 located on the front side of the rolling roller 5, there are several pressing and positioning rollers 12 that can be adjusted in height and position at intervals, which can be adjusted according to the height of the stacked honeycomb core 1 and the finished product 4 of the fireproof and thermal insulation material. The thickness is adjusted in height and pressed against it all the time, which plays the role of longitudinal positioning before rolling.

[0034] The two sides of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com