Mixed polymer solution for capillary electrophoresis and method for preparing mixed polymer solution

A hybrid polymer and capillary electrophoresis technology, which is applied in biochemical equipment and methods, DNA preparation, microbiological determination/inspection, etc., can solve the problems that are difficult to achieve in the laboratory, cumbersome synthesis steps, and large molecular weight requirements, and achieve good results. The effect of DNA separation ability, simple preparation method and great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

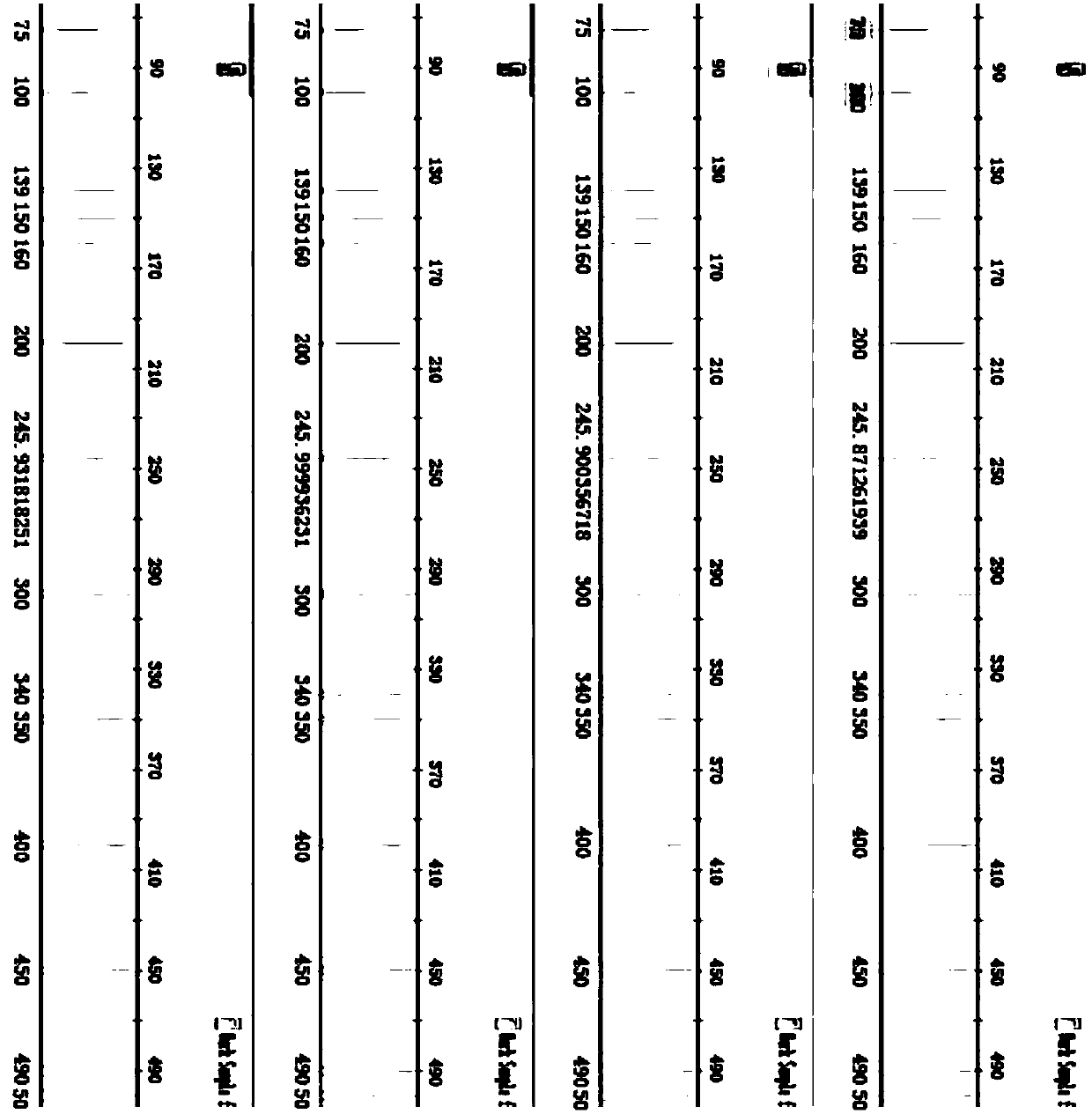

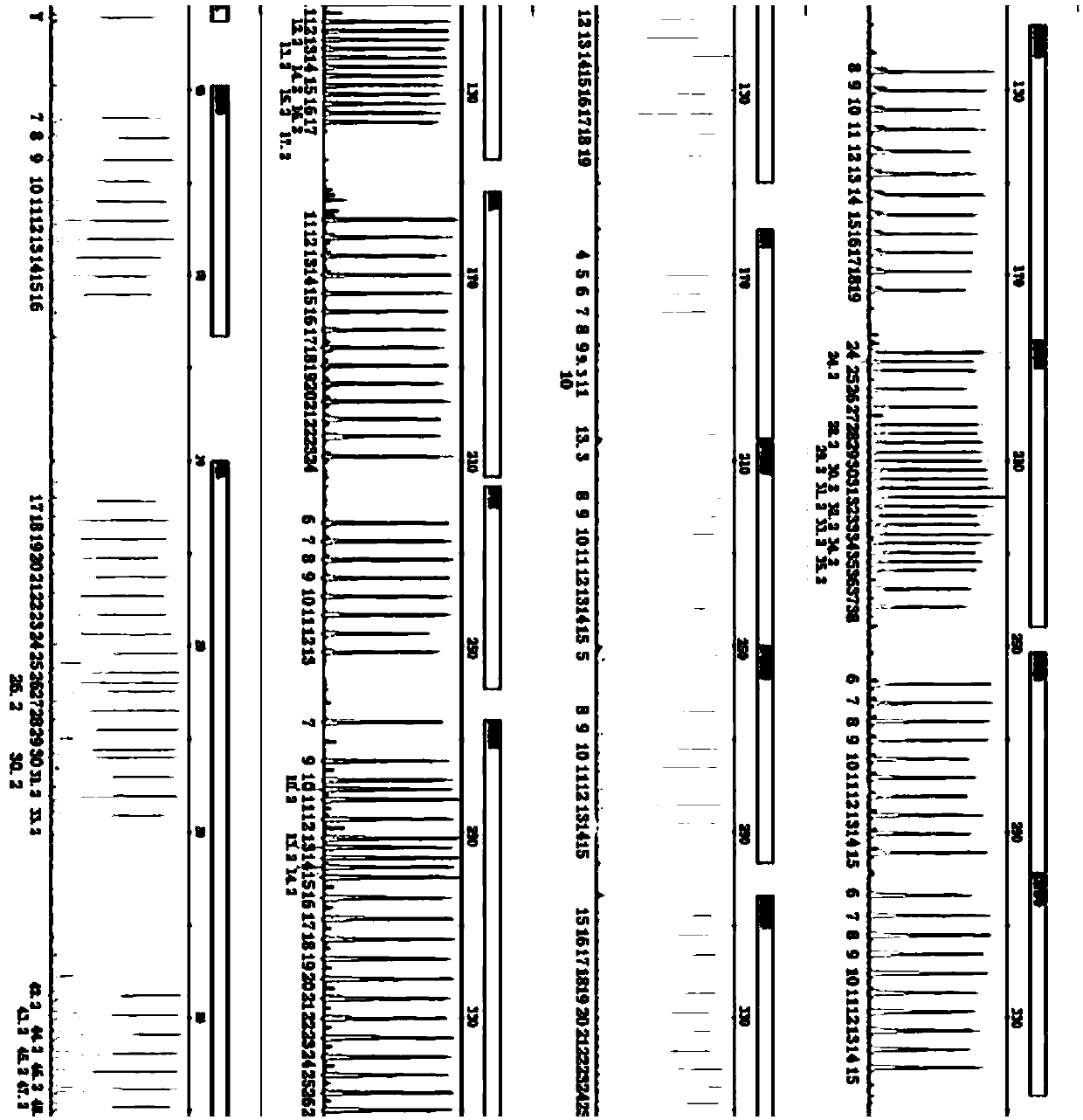

[0031] Embodiment 1, the preparation of polyacrylamide

[0032] Add 222ml of deionized water and 6.55ml of isopropanol into a round bottom flask, deoxygenate the solution with high-purity nitrogen (99.99%) at 35°C for 10min. Then add 25g of acrylamide (AM), 1.25ml of 10% (w / v) ammonium persulfate (APS) and 1.25ml of 10% (v / v) of N,N,N',N'-tetramethyldi Ethylamine (TEMED), after reacting for 90 minutes, the solution was viscous like honey. Dialysis was performed for three days using a dialysis bag (Spectra / por#2, Spectrum Medical Industries, Los Angeles, CA) with a molecular weight cut-off of 12-14 KDa. After dialysis, the polymer solution was freeze-dried to obtain a white solid with a reaction yield of 80%.

Embodiment 2

[0033] Embodiment 2, the preparation of poly N, N-dimethylacrylamide

[0034] Add 220ml of deionized water, 7.6ml of isopropanol and 24ml of N,N-dimethylacrylamide into a round bottom flask, deoxygenate the solution with high-purity nitrogen (99.99%) for 30min, put it in a water bath at 50°C for 20min, and then add 0.625ml 10% (w / v) of ammonium persulfate (APS) and 0.625ml 10% (v / v) of N,N,N',N'-tetramethyldiethylamine (TEMED), placed at 50 ℃ water bath after reaction for 3h. Dialysis was performed for three days using a dialysis bag (Spectra / por#2, Spectrum Medical Industries, Los Angeles, CA) with a molecular weight cut-off of 12-14 KDa. After dialysis, the polymer solution was freeze-dried to obtain a white solid with a reaction yield of 89%.

Embodiment 3

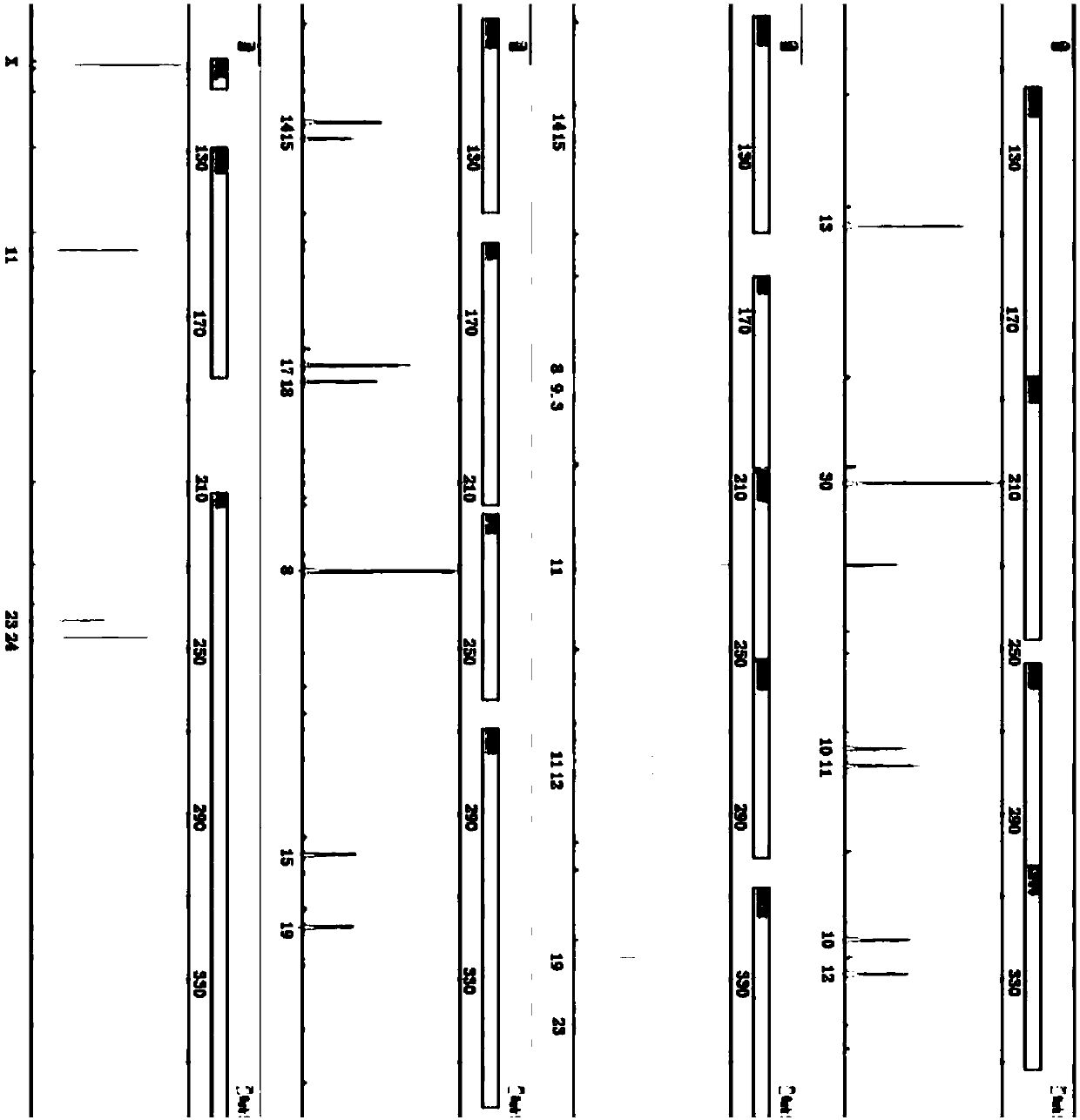

[0035] Embodiment 3, the preparation of mixed polymer solution

[0036] 1. Preparation of sol buffer

[0037] Weigh 19g of urea, add it to a clean 100ml volumetric flask, add 5ml 10×310and 31xxRunning Buffer (Applied Biosystems, USA), shake gently by hand until all urea is dissolved, add deionized water to make up to 50ml.

[0038] 2. Preparation of mixed polymer solution

[0039] Polyacrylamide and poly-N,N-dimethylacrylamide according to the ratio of 1.5:1, add 50ml of sol buffer, and swell overnight. Use a 0.2μm filter to filter and collect the filtrate into a clean volumetric flask. Store at 4°C to prevent urea degradation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com