Method for improving floor embossing forming efficiency

An embossing and high-efficiency technology, applied in roads, road repairs, roads, etc., can solve problems such as low efficiency, workers are prone to fall, and reduce the stability of workers, so as to achieve the effect of improving stability and improving forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

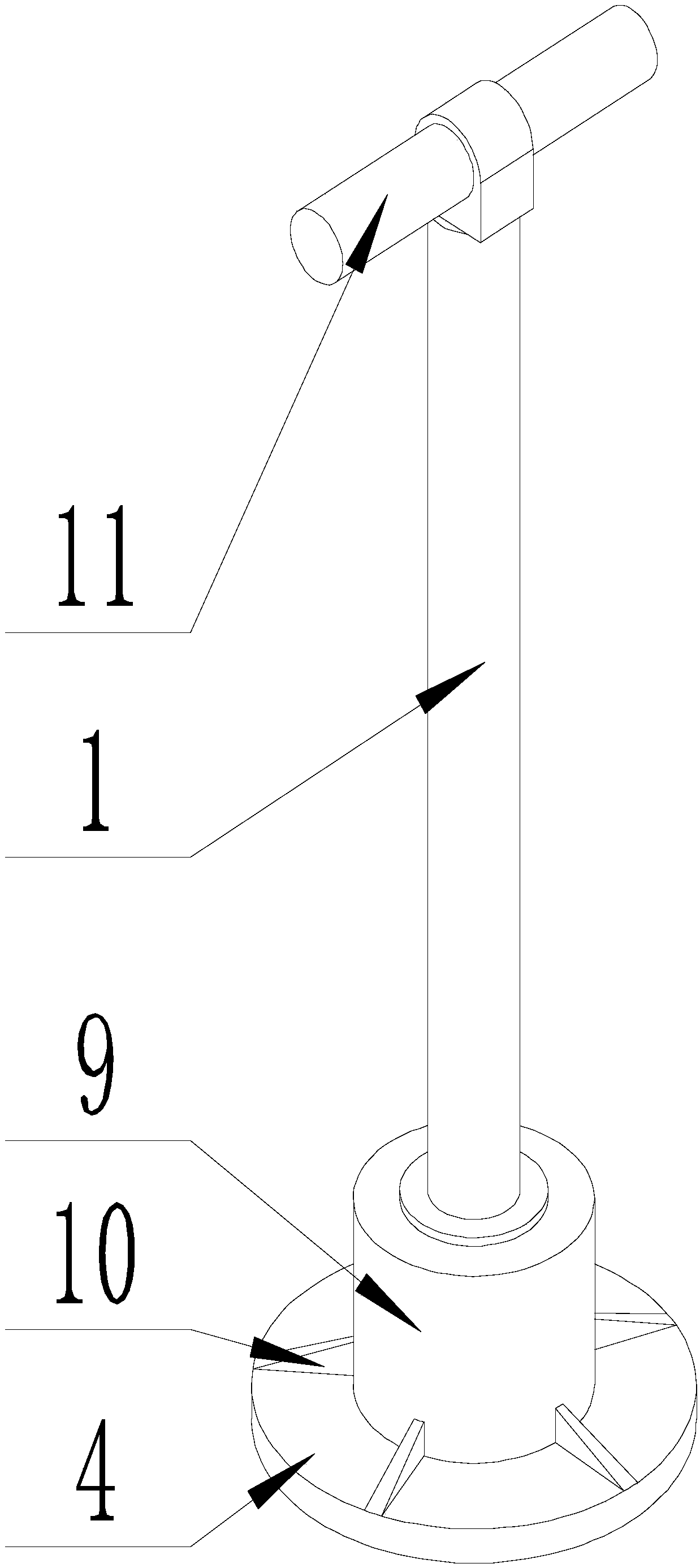

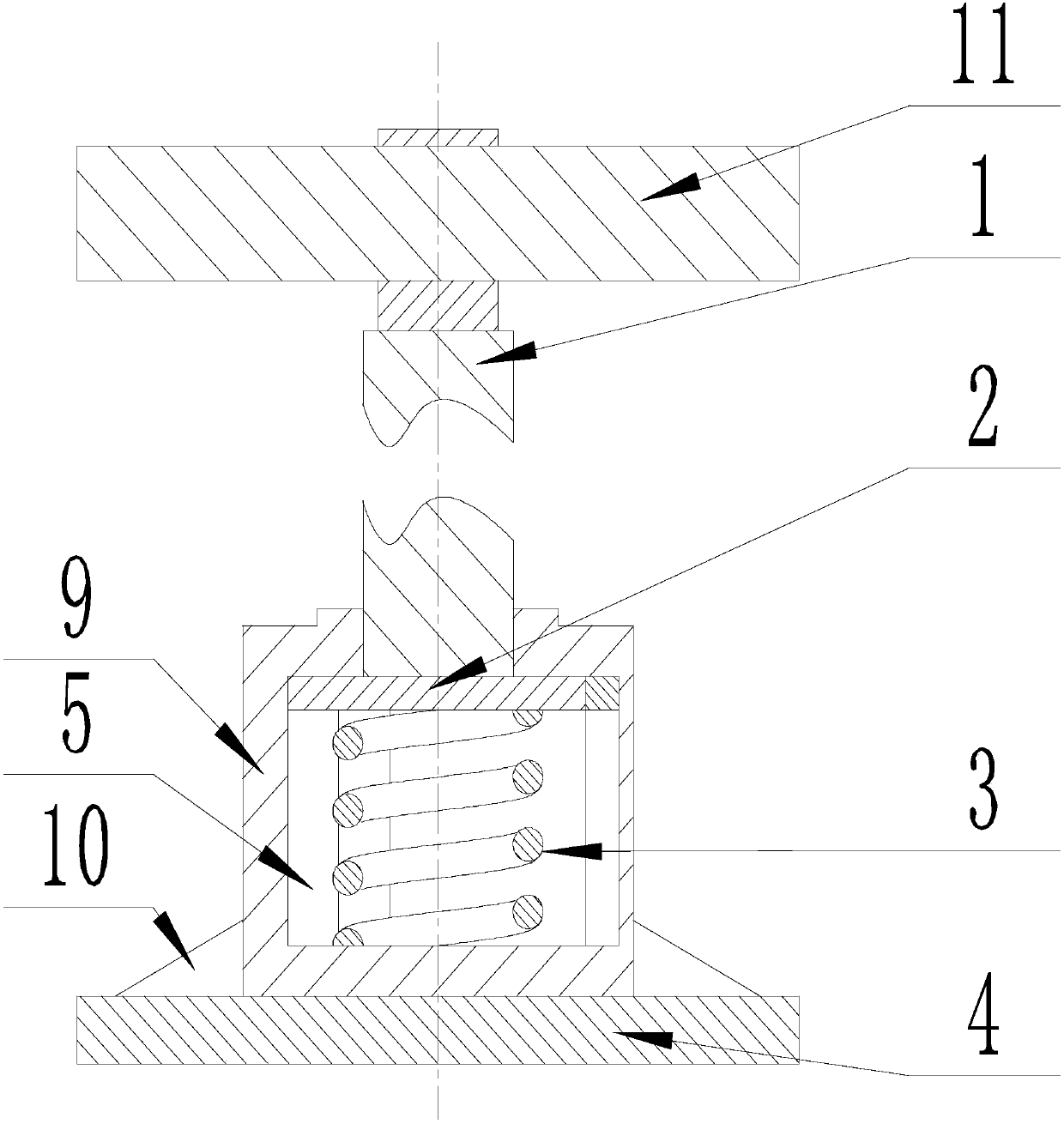

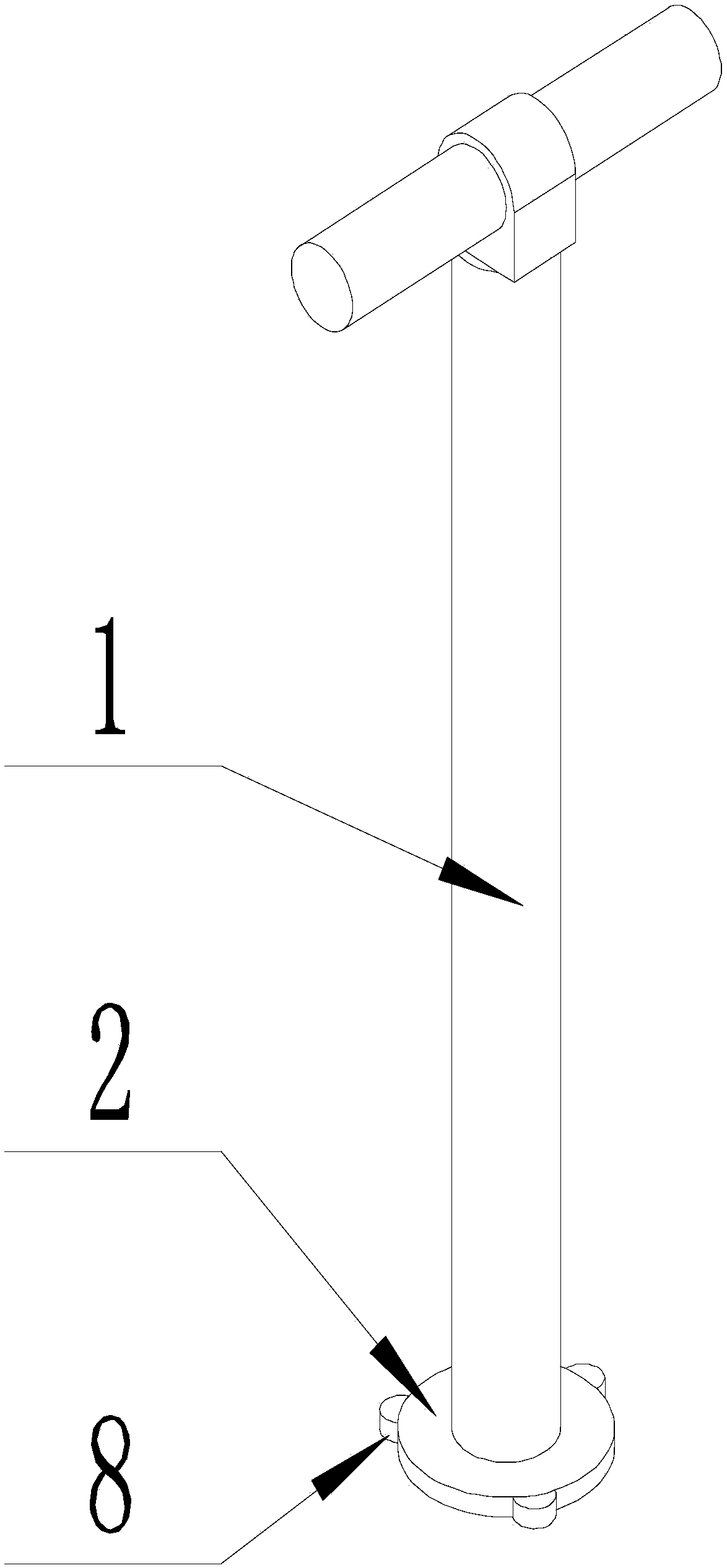

[0040] Such as Figure 1-Figure 5 As shown, the method for improving floor embossing forming efficiency of the present invention comprises the following steps:

[0041] Step A: laying concrete on the construction ground, and smoothing the upper surface of the concrete;

[0042] Step B: spreading powder on the upper surface of the concrete;

[0043] Step C: placing the embossing mold on the concrete surface sprinkled with powder;

[0044] Step D: Hold the end of the force application rod 1 away from the limit plate 2, and then move the force application rod 1 so that the force application cylinder 9 and the force application plate 4 are located above the embossing mold that needs to be applied, and then downward Move the force application rod 1, the limit plate 4 is in contact with the spring 3, the force application plate 4 is in contact with the embossing mold, and then continue to apply force downwards until the punch on the forming surface of the embossing mold overwhelms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com