Universal self-recovery anti-collision ground pile

A self-recovery and anti-collision technology, applied in roads, buildings, road safety devices, etc., can solve the problems of inconvenient installation and adjustment, limited number of impacts, easy damage, etc., and achieve low cost, avoid rain, and facilitate installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

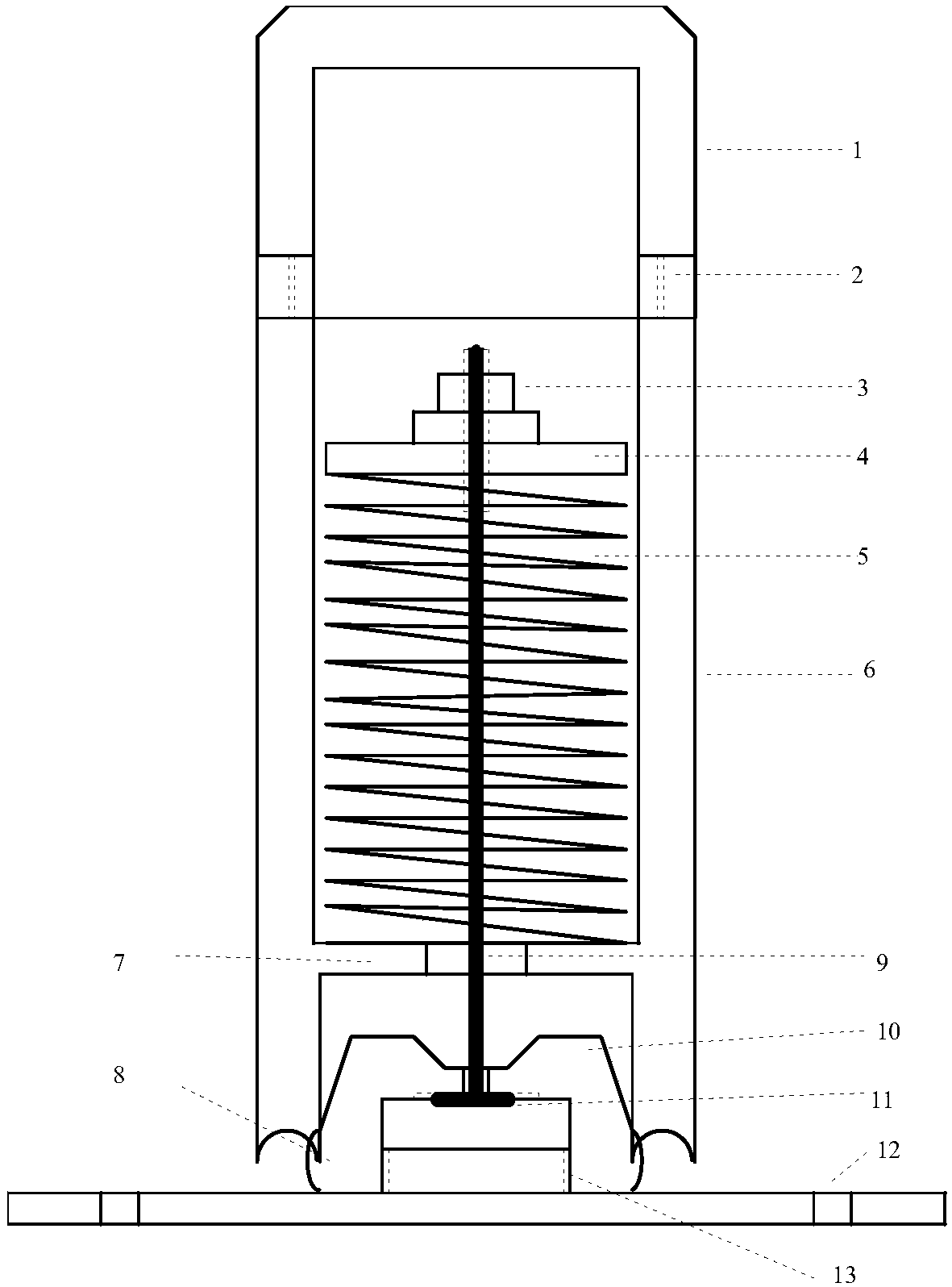

[0021] Such as figure 1 As shown, the universal self-restoring anti-collision ground pile of the present invention comprises a base (10), a pile body (6), a torsion column (9), a compression spring (5) and a pile cap (1); the base (10 ) is a circular platform column, the bottom of the base (10) is provided with a concave circumferential groove (8), the center of the base (10) is provided with a through hole, and the bottom surface of the base (10) is provided with a notch The pile body (6) is a tubular structure, which is placed on the outside of the base (10), and the inside of the pile body (6) is welded with a spring plate (7) with a through hole in the middle, and the pile body (6) The upper part is connected with the pile cap (1) by screws, and the lower edge of the pile body (6) is arc-shaped; Tighten the nut (3); the compression spring (5) is sleeved on the torsion column (9), and placed in the cavity formed by the retaining spring plate (7) and the compression spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com