High-pressure, large-flow, low-temperature liquid nitrogen/helium heat exchange device

A heat exchange device, high flow technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of high temperature value, small flow, non-adjustable, etc. , The effect of reducing stress concentration and large cooling range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

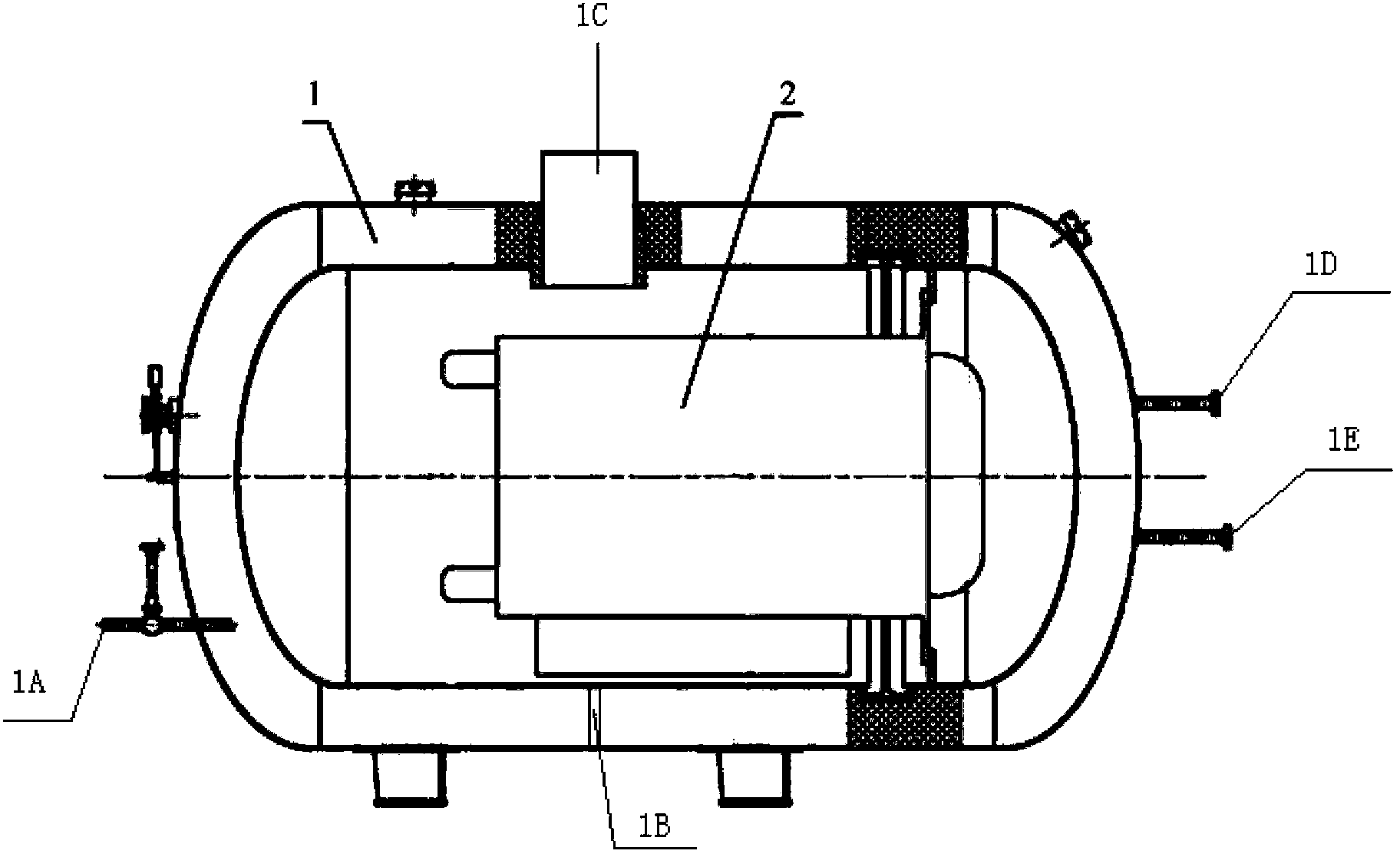

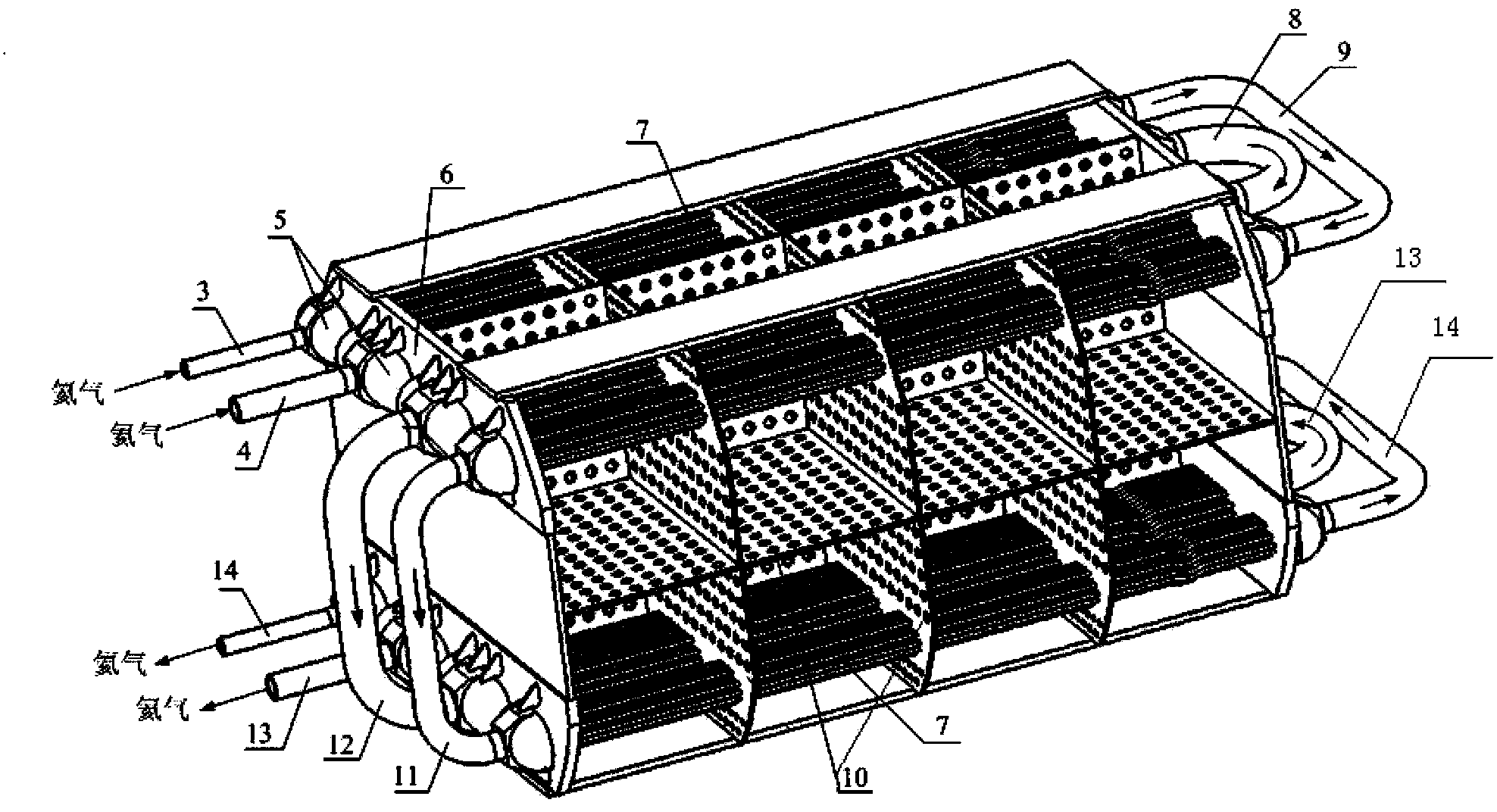

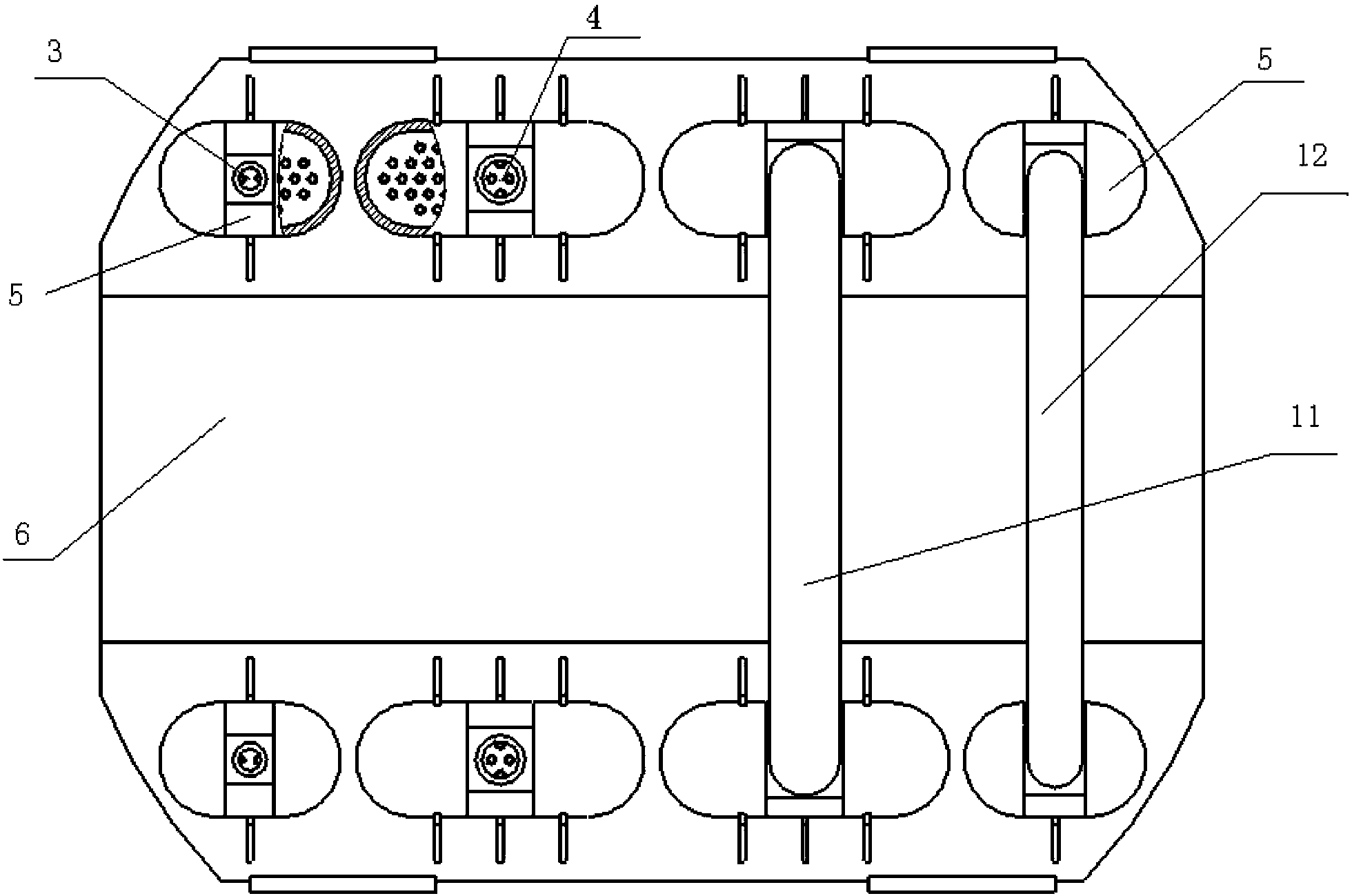

[0027] figure 1 and figure 2 It is a structural schematic diagram of an embodiment of the present invention. The liquid nitrogen / helium heat exchange device includes a shell 1 and a core 2 placed in the shell. The shell is provided with a liquid nitrogen inlet 1A, a liquid nitrogen outlet 1B, and a nitrogen gas Discharge port 1C, helium outlet 1D, helium inlet 1E, the heat exchanger core consists of helium inlet pipes 3, 4, gas collection chamber 5, tube sheet 6, heat exchange tube 7, connecting pipes 8, 9, 11, 12,15,16, helium outlet pipe 13,14 is formed.

[0028] like figure 1 , The heat exchanger core 2 is installed into the heat exchanger shell 1, and the shell is filled with liquid nitrogen. Helium enters the heat exchanger core 1 from the two helium inlet pipes 3 and 4 in two routes, then enters the gas collection chamber 5 welded on the tube sheet 6, and then passes through the heat exchange tube 7 behind the upper part in turn, Connecting pipes 8, 9, heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com