Anti-static ultra-silence motor casing

An ultra-quiet and anti-static technology, which is applied in the direction of static electricity, casing/cabinet/drawer parts, electrical equipment casing/cabinet/drawer, etc., which can solve the problems of reduced sealing performance, coil burnout, and end cover damage. To achieve the effect of ensuring sealing performance, convenient installation and preventing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

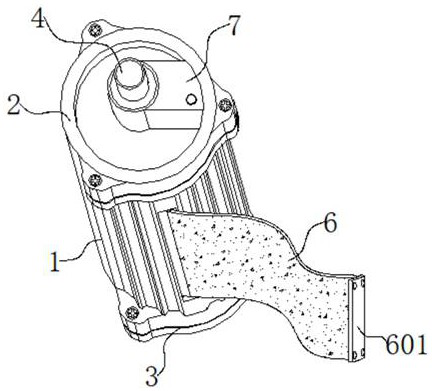

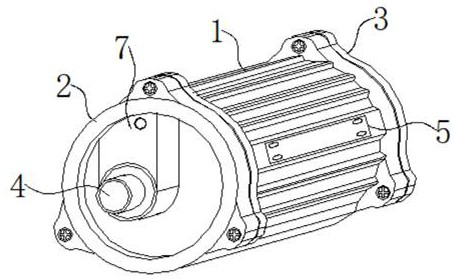

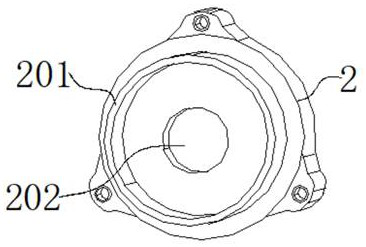

[0027] see Figure 1-9 middle,

[0028]An anti-static ultra-quiet motor casing provided in this embodiment includes a casing 1, a front end cover 2 and a rear end cover 3, one end of the casing 1 is fixedly connected to the front end cover 2 by bolts, and the other end of the casing 1 is passed through Bolts are fixedly connected with a rear end cover 3, and both ends of the casing 1 are provided with limiting grooves 101, and a cavity 102 is provided in the casing 1, and both sides of the cavity 102 are provided with arc-shaped slideways 103, two arc-shaped One end of the slideway 103 is fixedly connected with a first spring 104 by bolts, and one end of the two first springs 104 is fixedly connected with a stainless steel connecting plate 105 by bolts. A through hole 202 is opened, a rear limit ring 301 is provided on one side of the rear end cover 3, and a motor shaft 4 is provided in the casing 1. The motor shaft 4 includes a motor shaft, a stator and a rotor, and one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com