Continuously variable transmission driving chain composited with push blocks

A technology of continuously variable transmission and transmission chain, which is applied in the direction of transmission chain, transmission device, chain ring, etc., which can solve the problems that the push type transmission chain cannot be bent too much, the flexible steel belt ring is easy to fatigue and fracture, and the continuously variable transmission is damaged, so as to improve the grip Power and the ability to break the oil film on the surface of the cone, good anti-skid and heat dissipation effects, and the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be further described with reference to the drawings.

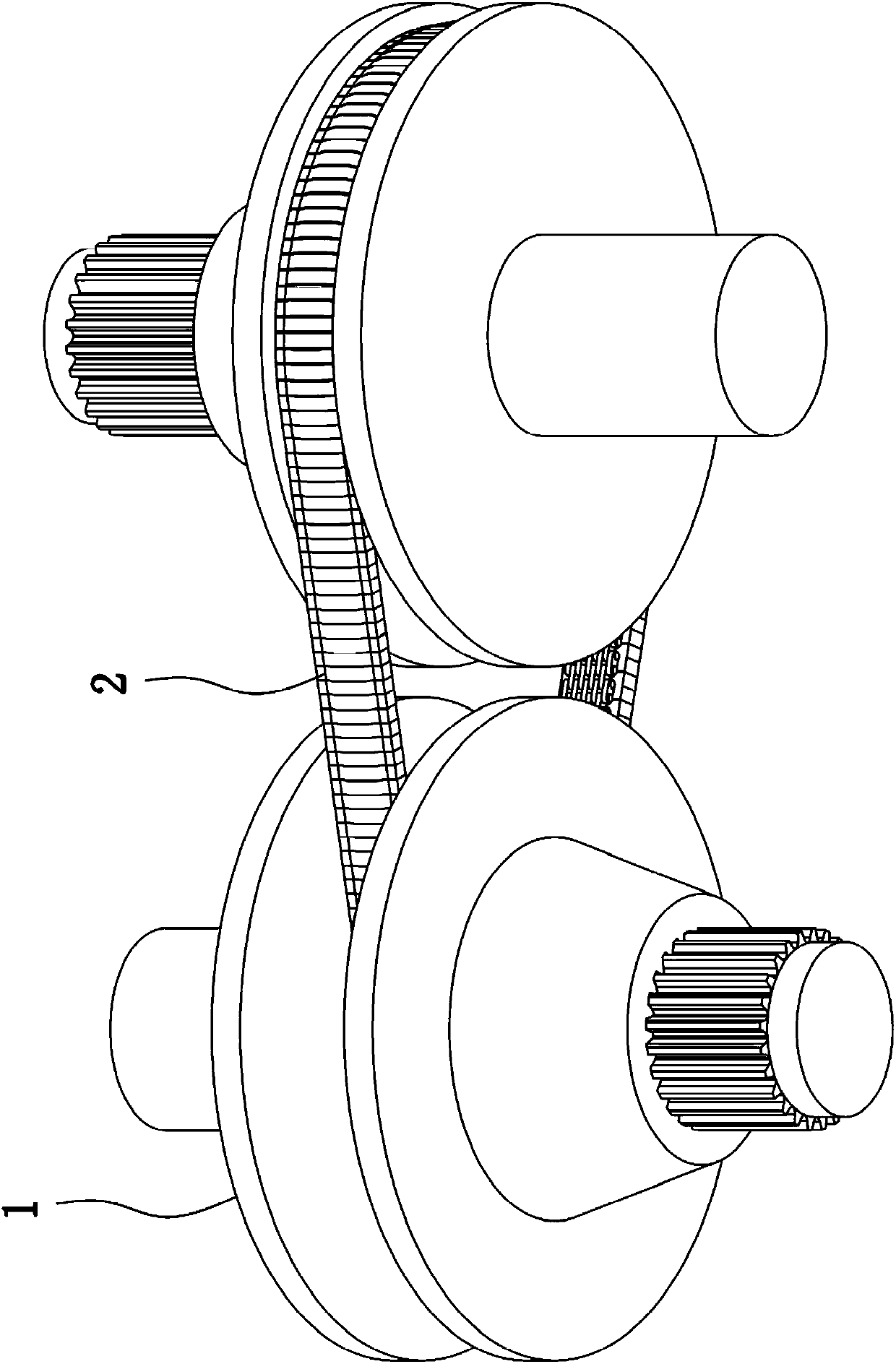

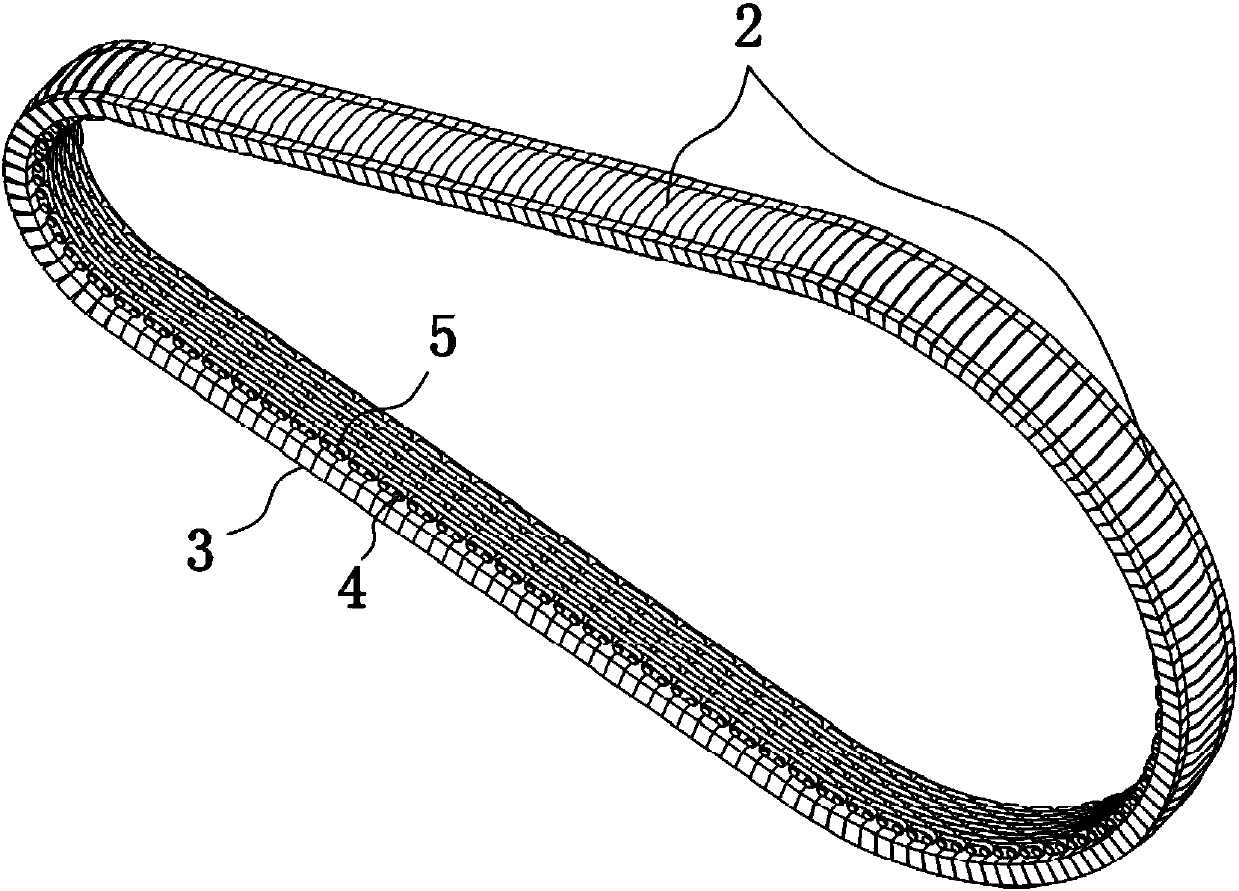

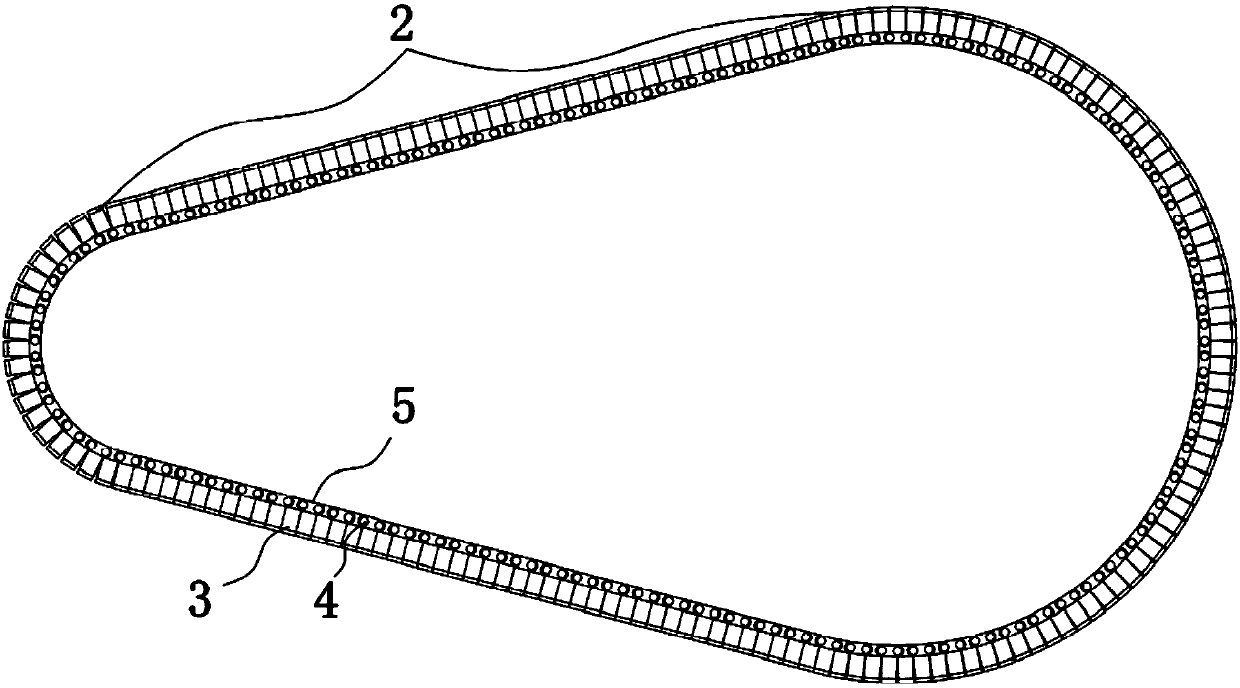

[0026] Such as figure 1 , 2 , 3, 5, 6, and 7, a push block composite continuously variable transmission chain, comprising: a plurality of chain links (5) and chain pins (4) connecting a plurality of chain links (5), characterized in that: The chain link (5) is composed of a chain link piece set (18) and a push block (3) integrally arranged with the chain link piece set (18). The push block (3) forms a contact portion, which transmits power under the pushing action of the chain link (5).

[0027] Such as figure 2 , 3 , 4, 5, the push block (3) is located at the upper end of the chain link sheet group (18); or, as Image 6 , 7 , 8, shown in 9, push block (3) is divided into push block (15) and push block (16) down, is located at the upper end and the lower end of chain link sheet group (18) respectively. The upper and lower push blocks are in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com