Special connecting sealing disc for waste carclazyte treatment equipment

A technology for processing equipment and waste clay, which is applied to the sealing of engines, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of looseness, insufficient pipe connection, affecting the normal use of processing equipment, etc. The effect of strong connection and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

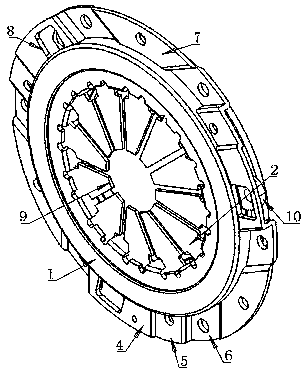

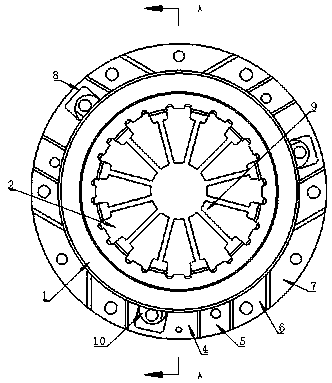

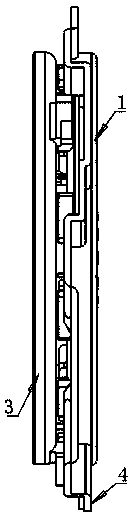

[0021] Such as Figure 1 to Figure 8 As shown in the figure, a special connecting sealing disc of waste clay processing equipment is mainly used in the main connecting pipes of pyrolysis processing equipment, which can make the connection effect of the connecting pipes better, and the operation is more convenient during assembly, and the assembly is completed Finally, it can also play a certain anti-loosening effect on the pipeline, so that it is not easy to loosen during long-term use, and the later use effect is more stable. In addition, the production cost of this part is relatively low, which can reduce the pyrolysis treatment equipment as a whole. use cost. It includes a cylindrical main assembly structure 1, which is a main structural member. The main assembly structure 1 is integrally molded from sheet metal through die embossing, which is more convenient in production, and this production method makes the structural strength of the parts better. The cost of parts pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com