A mixed gas modification method for a 110kv sulfur hexafluoride gas-insulated current transformer

A technology of sulfur hexafluoride gas and current transformer, which is applied in the method of container discharge, container filling method, gas treatment/storage purpose, etc., can solve the complex internal structure of CT, prone to insulation failure, cost and long cycle, etc. problems, to achieve the effect of convenient operation, restraining absolute growth, and reducing replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

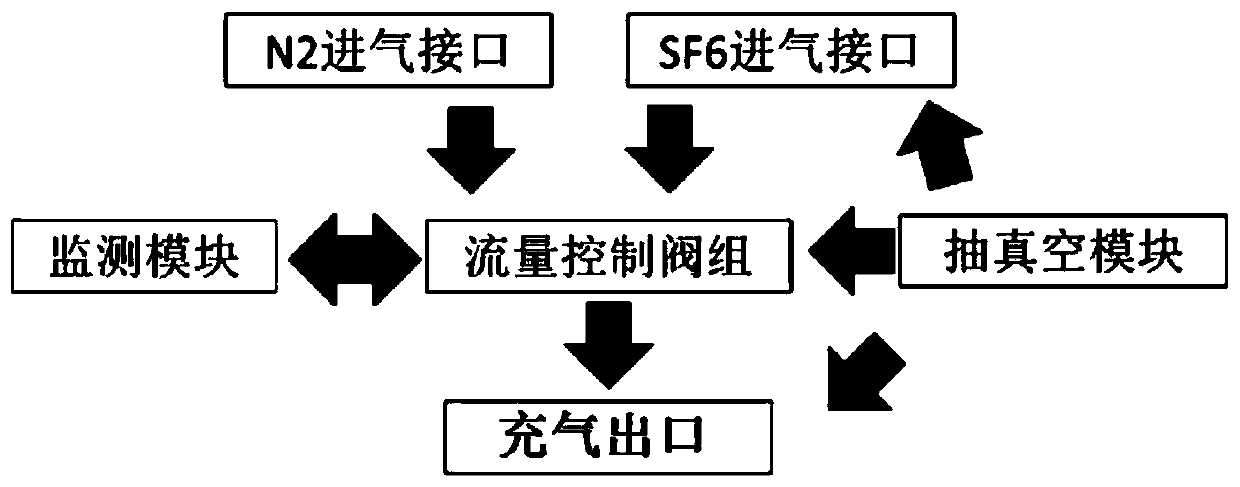

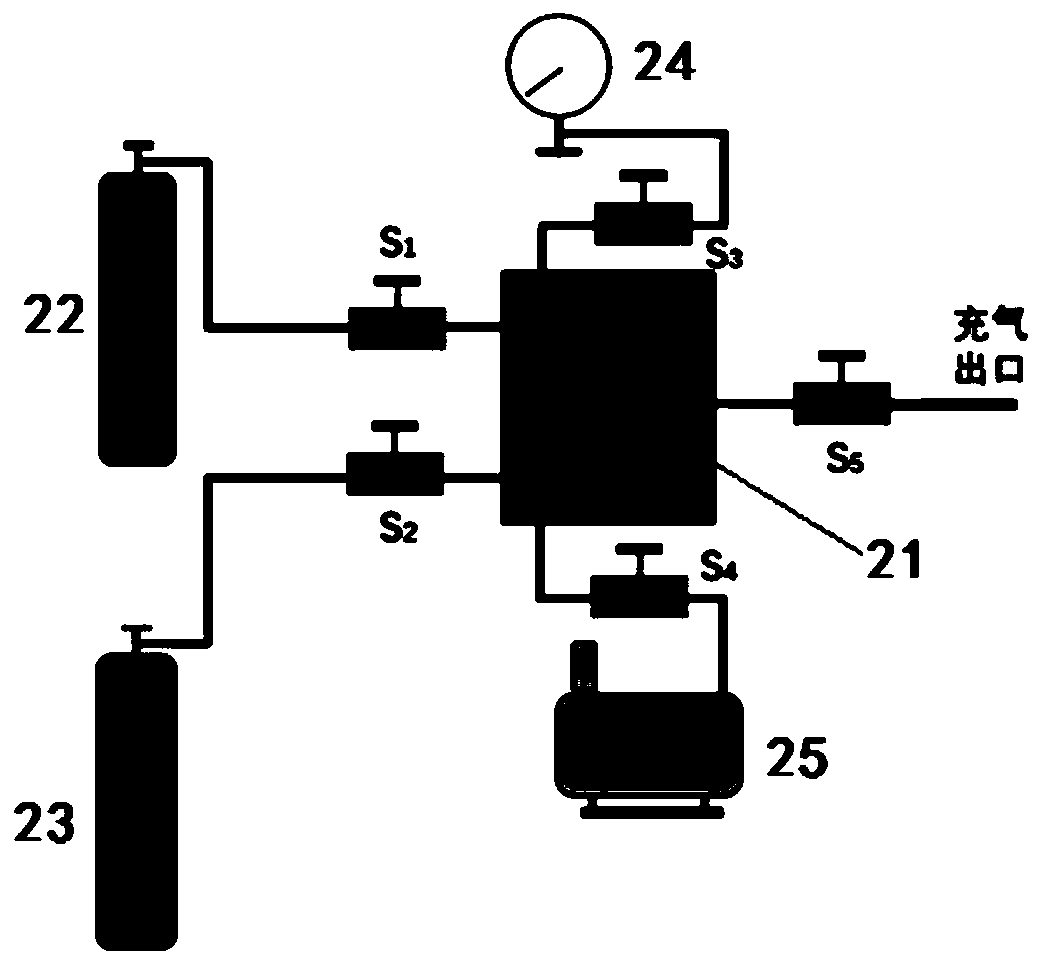

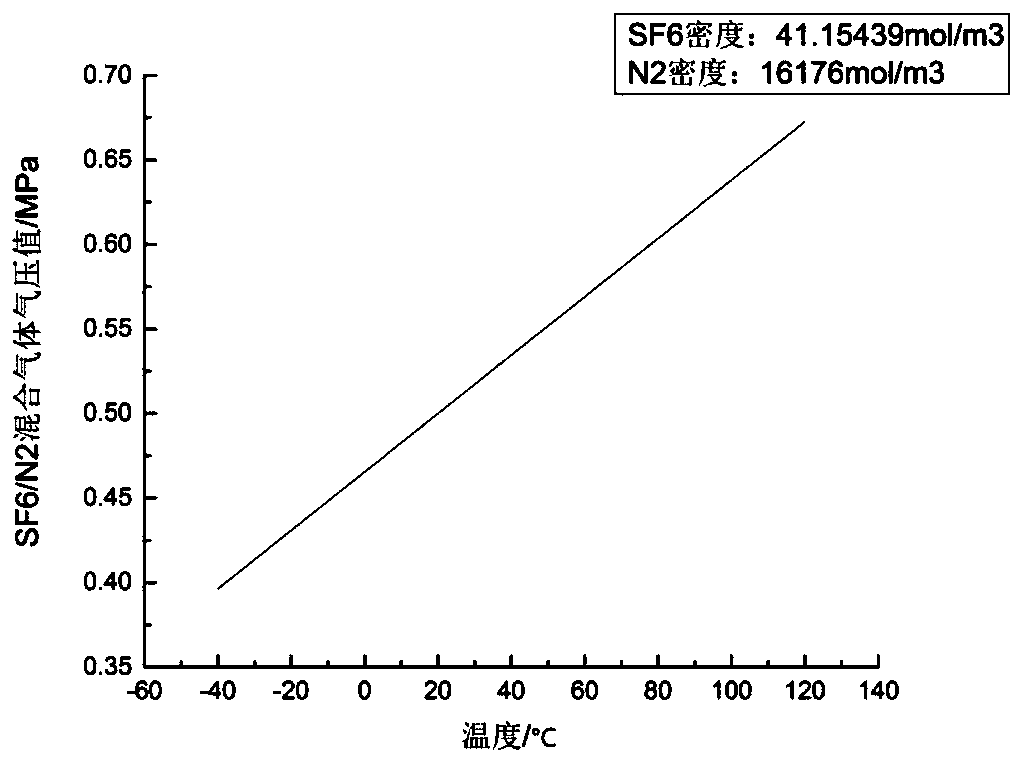

[0031] A mixed gas modification method for a 110kV sulfur hexafluoride gas-insulated current transformer of the present invention comprises the following steps: Step 1, using the original SF 6 The body of the gas-insulated current transformer, and re-check the relationship between the pressure of the porcelain bottle of the gas chamber, the pressure of the explosion-proof membrane, and the pressure of the two and the inflation pressure of the mixed gas. If necessary, the explosion-proof membrane of the gas chamber of the current transformer needs to be replaced to ensure The pressure ratio of explosion-proof membrane SF 6 / N 2 The pressure of the mixed gas is at least 0.4MPa; step 2, the SF 6 SF in gas insulated current transformer 6 Gas recovery, use the recovery device to recover the original SF 6 SF in gas insulated current tra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap