Calculation method of rotation error and roundness error based on hybrid four-point method based on three-point method

A technology of roundness error and rotation error, which is applied in the field of calculation of rotation error and roundness error based on the hybrid four-point method based on the three-point method, can solve the problem of three-point method with few operation steps, and achieve accurate, stable and easy measurement results. The effect of less understanding and operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

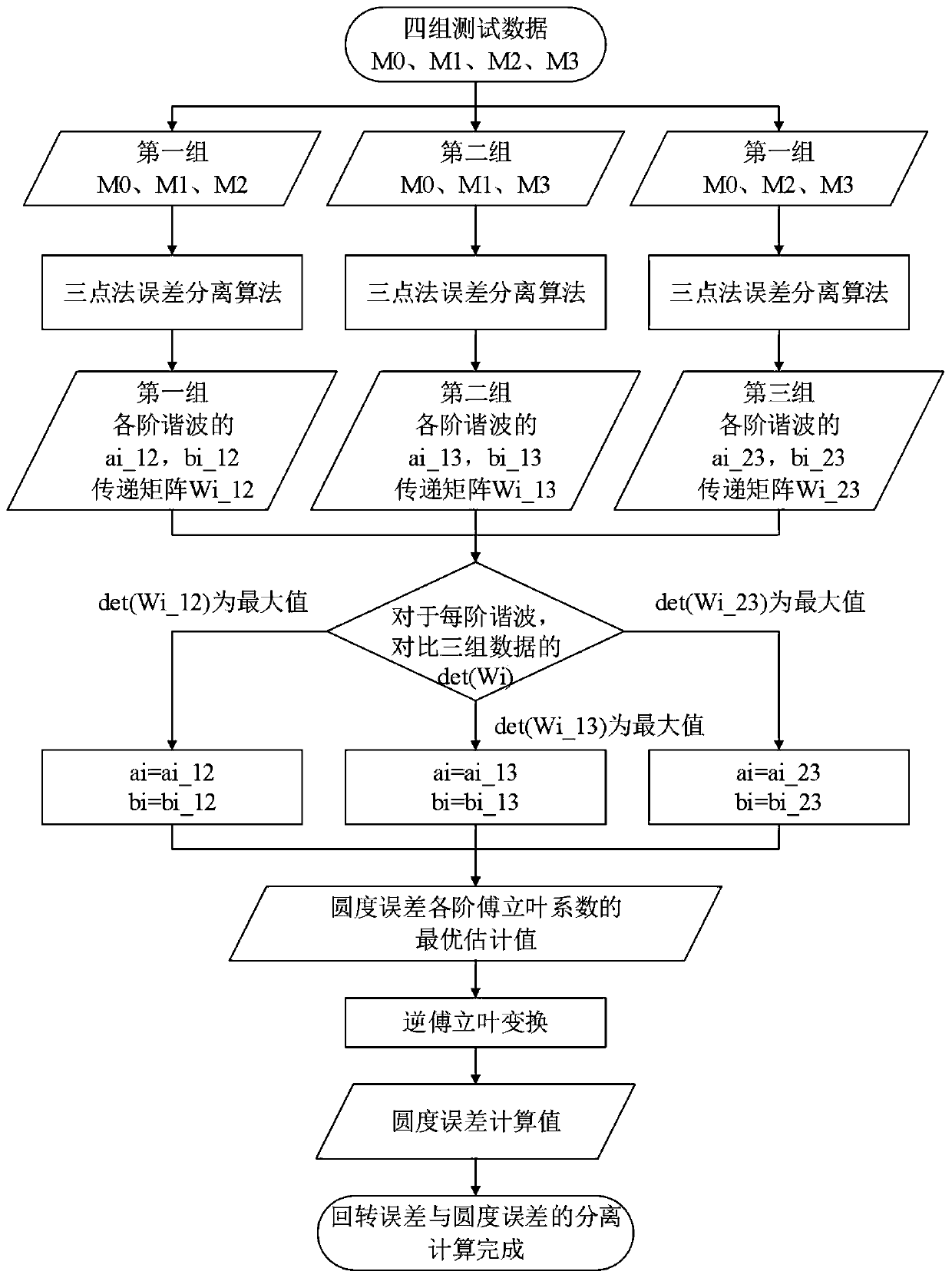

[0029] refer to figure 1 , a calculation method for rotation error and roundness error based on the hybrid four-point method of the three-point method, including the following steps:

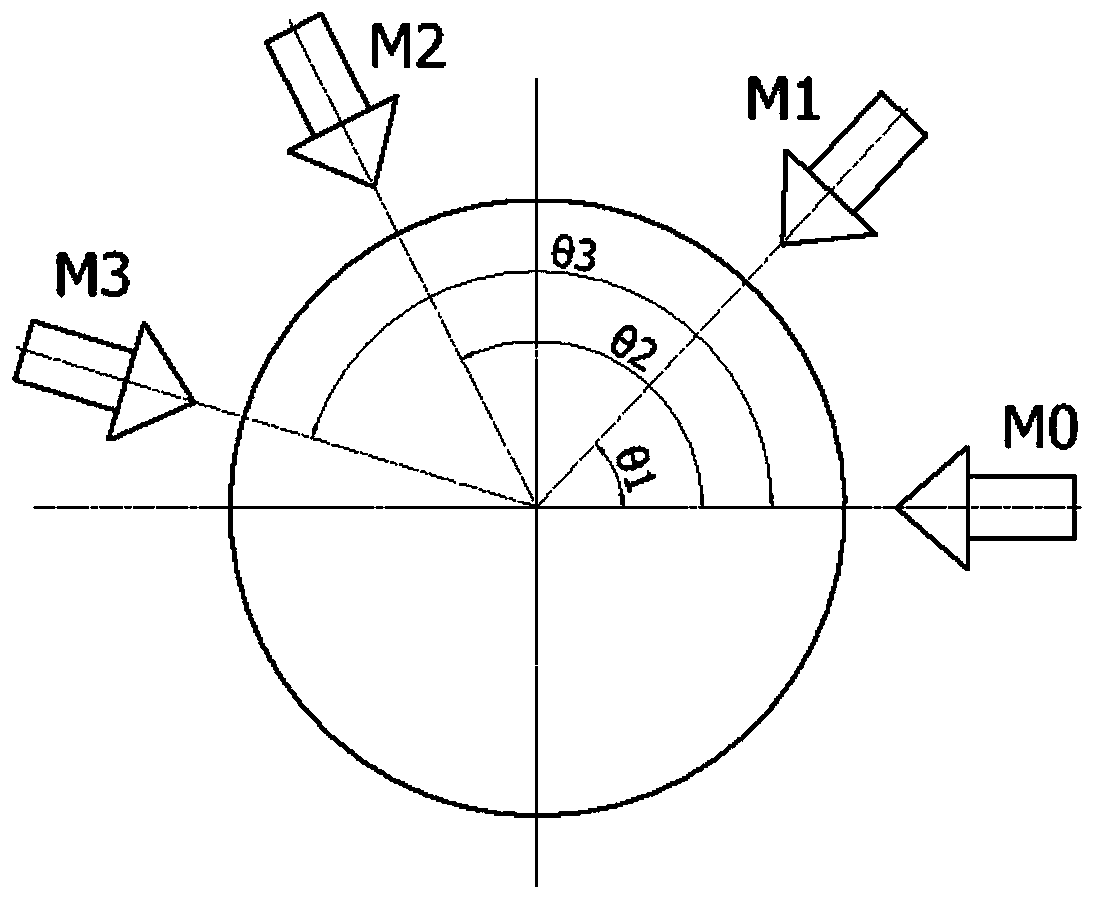

[0030] Step one, such as figure 2 As shown, in the same section perpendicular to the axial direction of the rotary shaft, align the four displacement sensors with the axis of the rotary shaft, and press the angle [0,θ 1 ,θ 2 ,θ 3 ] arrangement, where θ 1 = 20°, θ 2 =90°, θ 3 = 150°, after the rotary shaft starts to rotate, the four displacement sensors sample 500 points per circle, and respectively measure the radial runout signal M of the outer surface of the rotary shaft 0 , M 1 , M 2 , M 3 ;

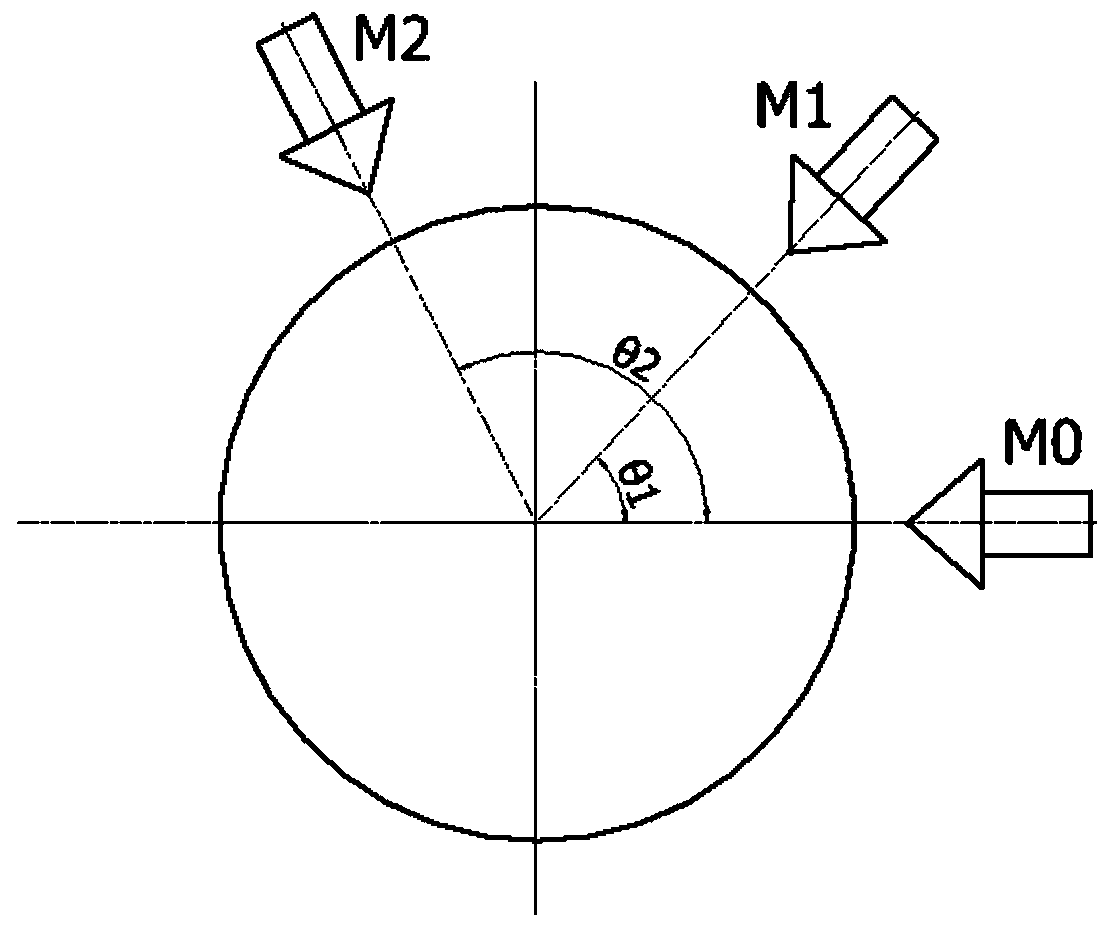

[0031] Step 2, divide the four signals into three groups, M 0 , M 1 , M 2 for the first group, such as image 3 Shown; M 0 , M 1 , M 3 for the second group, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com