Test paper color reaction accelerating device

A technology of reaction acceleration and test paper, which is applied to measuring devices, analyzing materials through chemical reactions, instruments, etc., can solve problems such as inaccurate detection results, insufficient liquid to be tested, and limited siphoning capacity, so as to speed up the siphoning effect, Good color rendering and increased flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

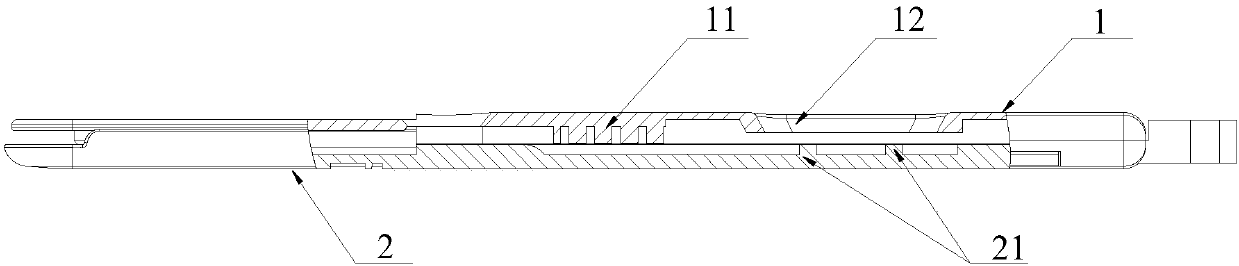

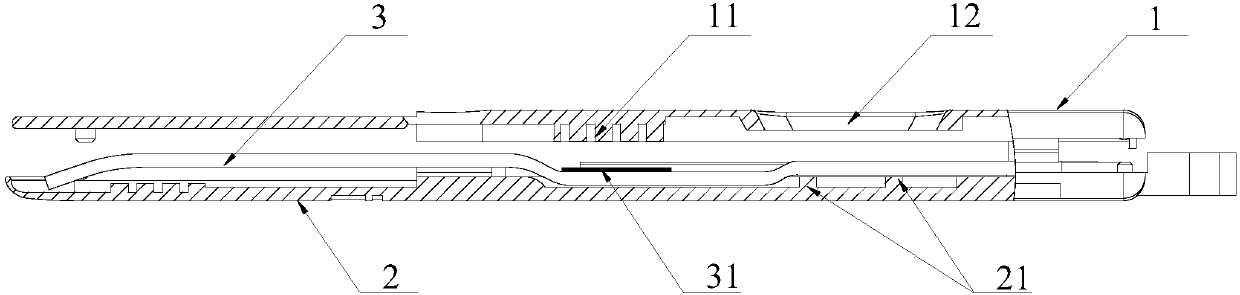

[0028] like figure 1 , 2 As shown, the test paper color reaction acceleration device of this embodiment includes a lower support body 2 and an upper cover body 1 that are fastened together to fix the test paper; Extrusion structure 11 for extruding dyed layer of test paper, reaction color display window 12, said extrusion structure includes m extruded ribs and bones, and said extruded ribs and bones distance is arranged in the siphon direction of said test paper, wherein, m≥ 2, and is an integer;

[0029] A groove is provided on the lower support body, and a number of supporting ribs 21 are arranged in the groove, and the test paper is horizontally supported by the upper edge surface of the groove and the supporting ribs;

[0030] When the test paper 3 is set in the fastened upper cover body and lower holder, the dyed layer of the test paper is correspondingly arranged in the groove, and the extrusion structure squeezes the dyed layer so that the The test paper was deformed...

Embodiment 2

[0033] The test paper color reaction acceleration device of this embodiment, on the basis of embodiment 1, the support tendons and bones are arranged in the area formed by the reaction color display window, the number of support tendons and bones of the support structure and the color rendering strip of the test paper The numbers correspond to each other, and when the test paper is set on the lower holder, each color strip of the test paper is correspondingly set on each supporting rib.

[0034] In this embodiment, in order to facilitate the acquisition of the display, the color strips are arranged on the supporting bones.

Embodiment 3

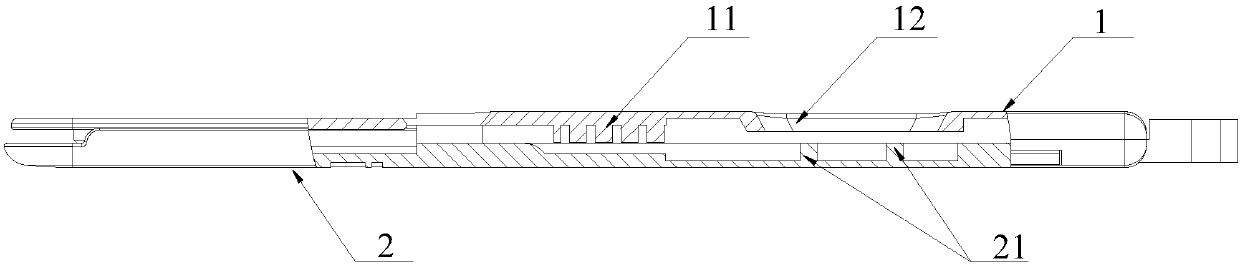

[0036] like image 3 , 4 As shown, the test paper color reaction acceleration device of this embodiment, on the basis of embodiment 1 or 2, the bottom surface of the groove is a first-level stepped structure 22, the upper step surface corresponds to the dyed layer of the test paper, and the lower step surface is in contact with the concave surface. The side walls of the tank and the steps form an overflow-proof water storage structure, and the supporting ribs are arranged on the lower step surface.

[0037] In this embodiment, in order to prevent excessive overflow of liquid, an anti-overflow water storage structure is arranged between the dyeing layer and the color strip in the direction of the liquid siphon, avoiding excessive liquid flowing out of the structure formed by the lower holder and the upper cover , clean and hygienic.

[0038] In each of the above embodiments, the deformation of the test paper in the vertical direction is that the height of the lower surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com