Marine aluminum alloy floor drain

An aluminum alloy and floor drain technology, which is applied in the field of ships, can solve the problems such as the lack of deodorant, insect-proof, anti-blocking, and hair-proof floor drain cores, the inability to meet the requirements for the use of ship floor drains, and the trouble of deodorizing and preventing crew members. The effect of strong practicability and great market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

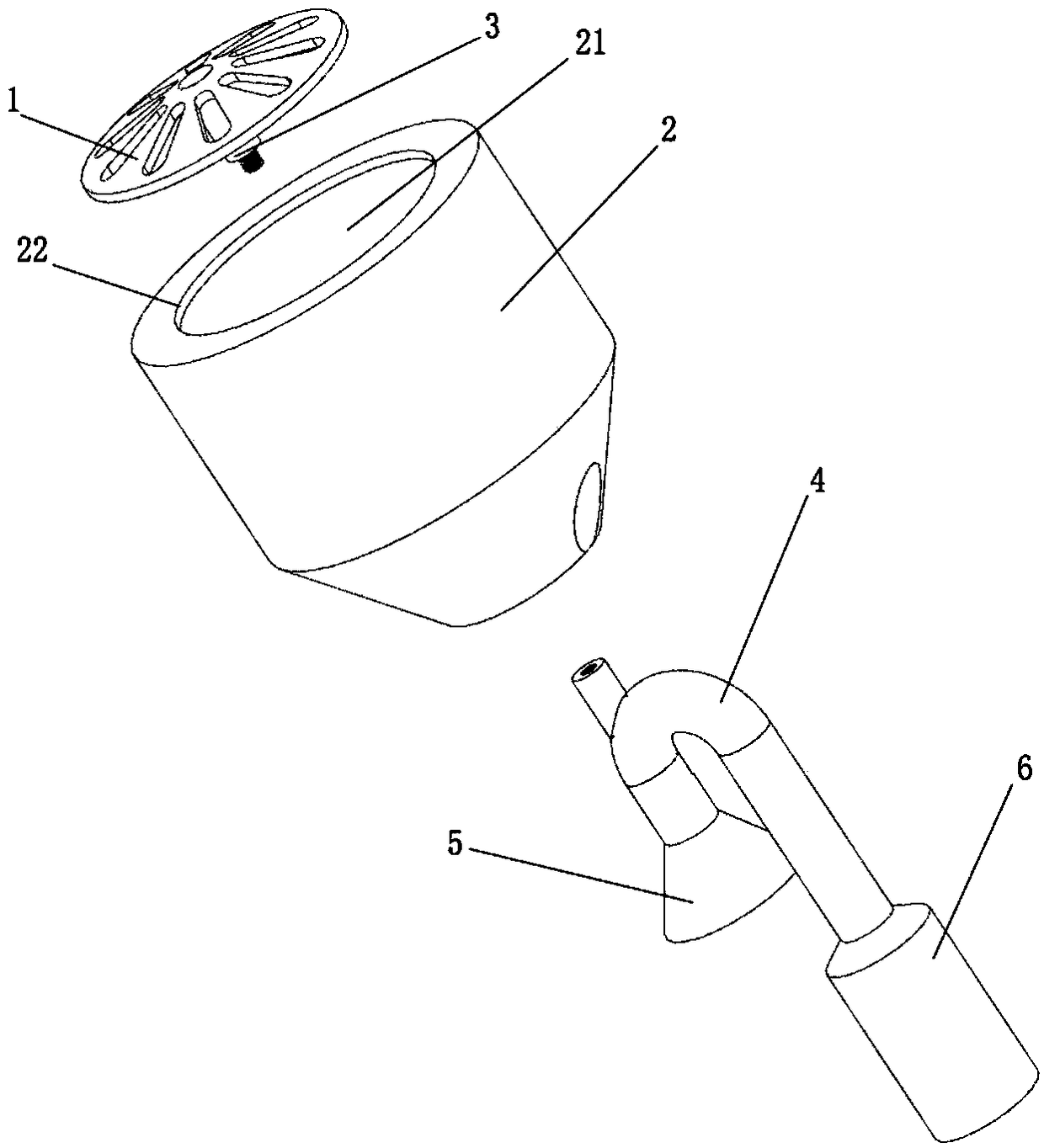

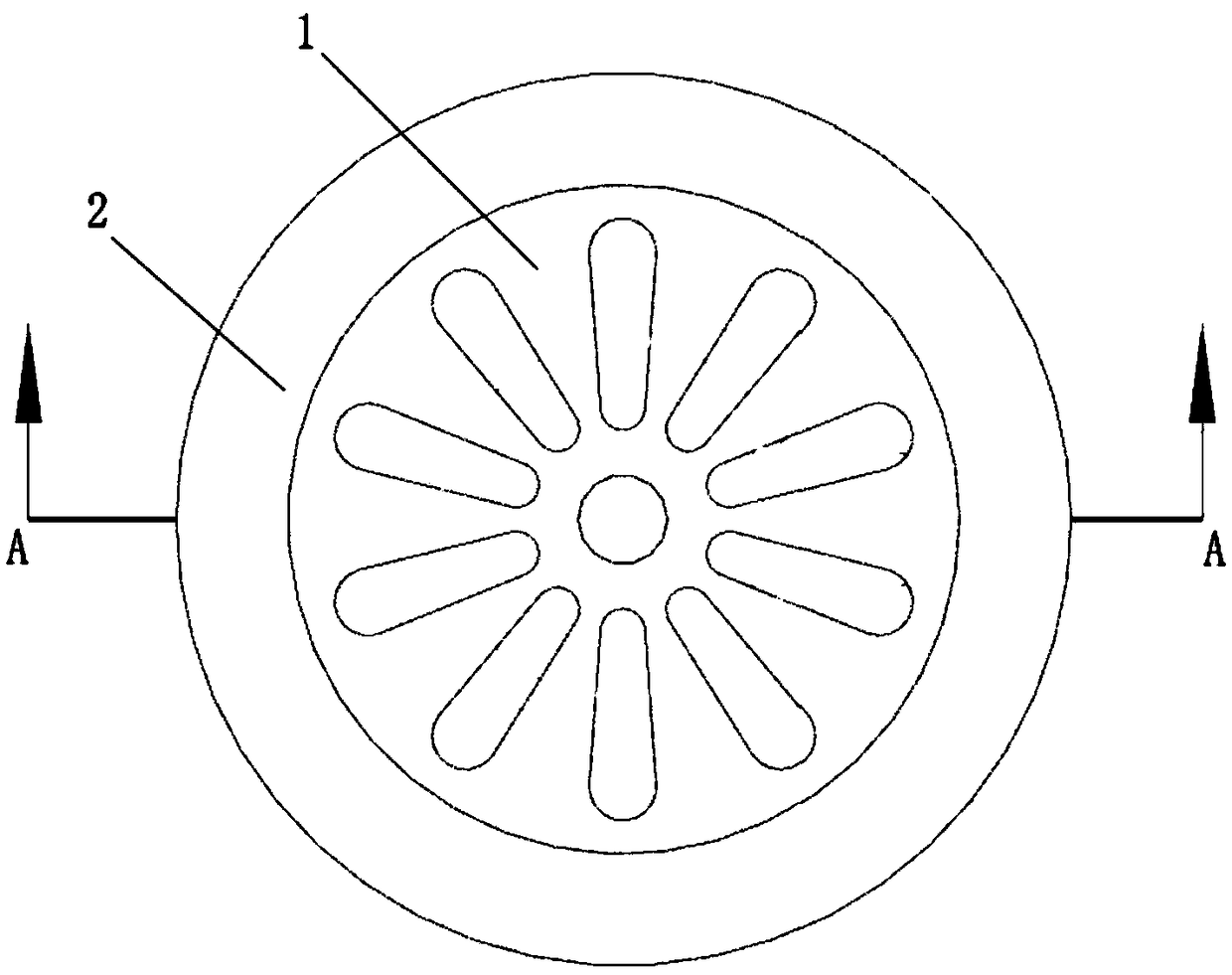

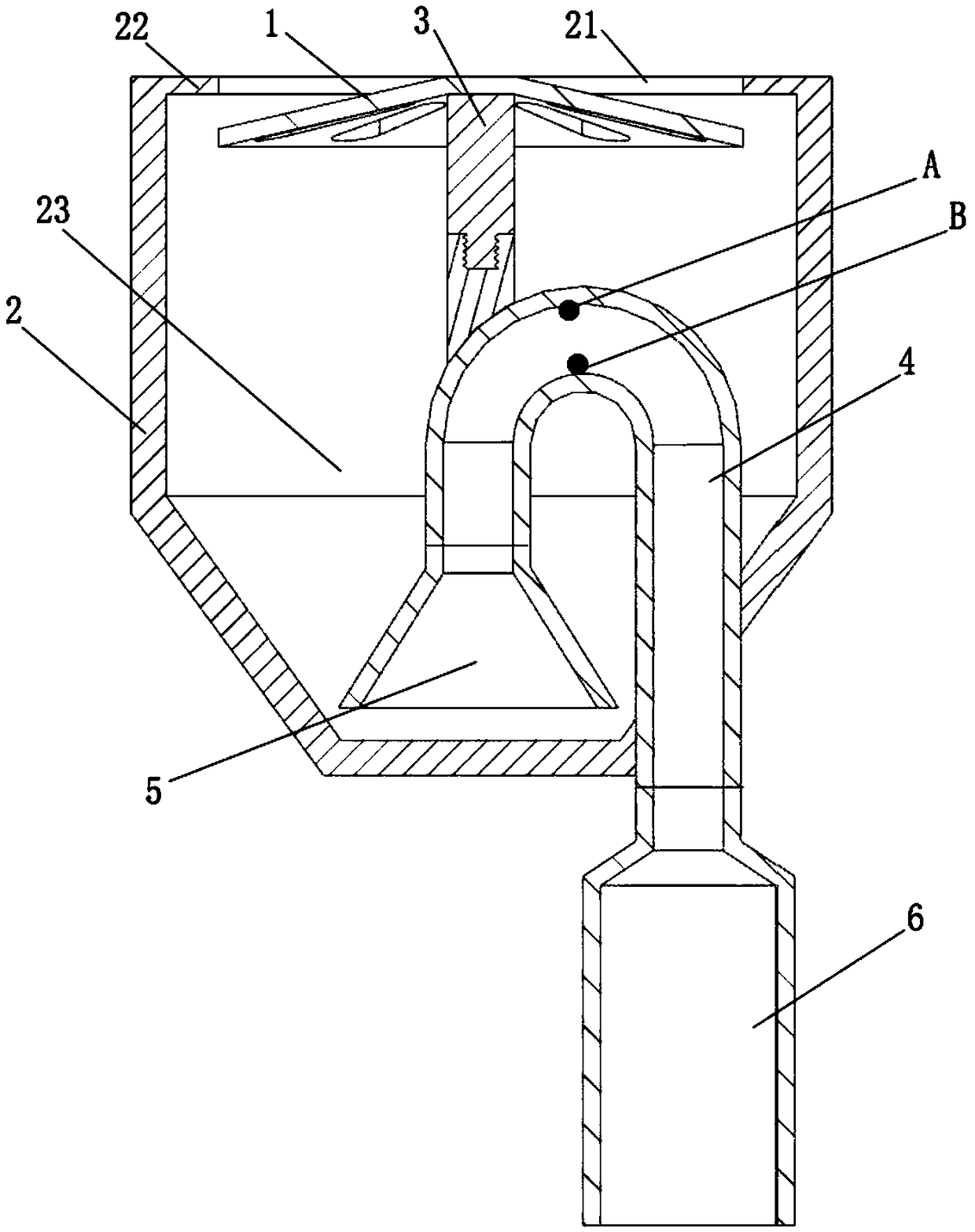

[0020] like Figure 1-2 As shown, a marine aluminum alloy floor drain includes a circular grate 1, a floor drain body 2 with a drainage inlet 21 and a drainage chamber 23, a column 3 and an inverted U-shaped pipe 4, and the grate 1 is arranged on the floor drain body 2, the bottom of the grate 1 is fixedly connected with a column 3, and the column 3 is used to support the grate 2. The inverted U-shaped tube 4 is fixedly installed inside the floor drain main body 2, and the nozzle at one end of the inverted U-shaped tube 4 is facing the center of the inner bottom surface of the floor drain body 2, and the nozzle at the other end of the inverted U-shaped tube 4 passes through the floor drain body 2 The bottom surface of the bottom surface, that is, the mouth of this end is located outside the grate 2, so that the drainage pipe can be connected; the end of the column 3 that is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com