Liquid crystal display panel

A liquid crystal display panel and liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as unevenness, liquid crystal pollution, bright and dark stripes, etc., to reduce costs, improve coating quality, and increase product qualification rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present disclosure will be described in detail with reference to specific embodiments.

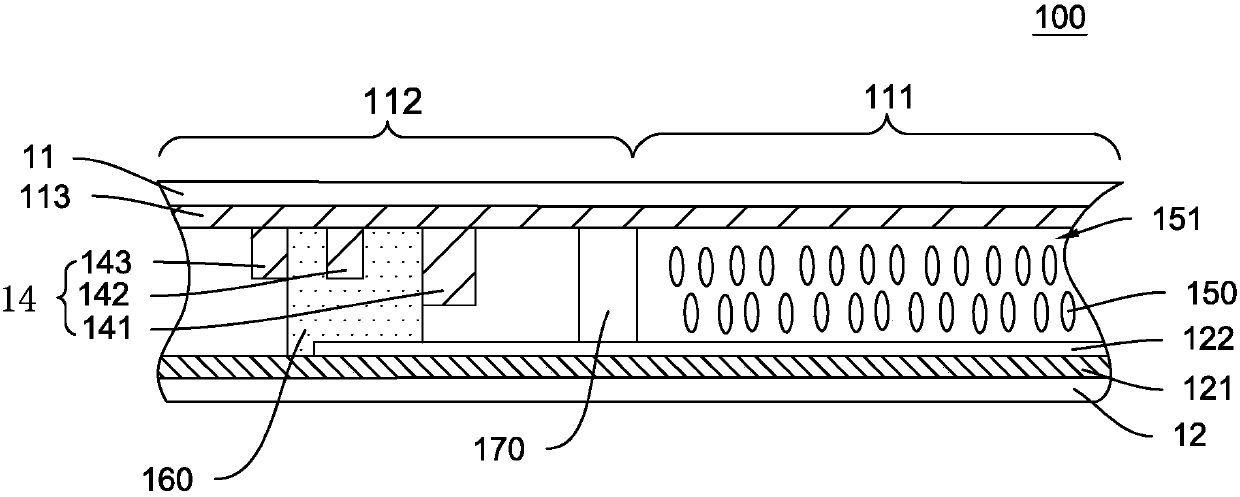

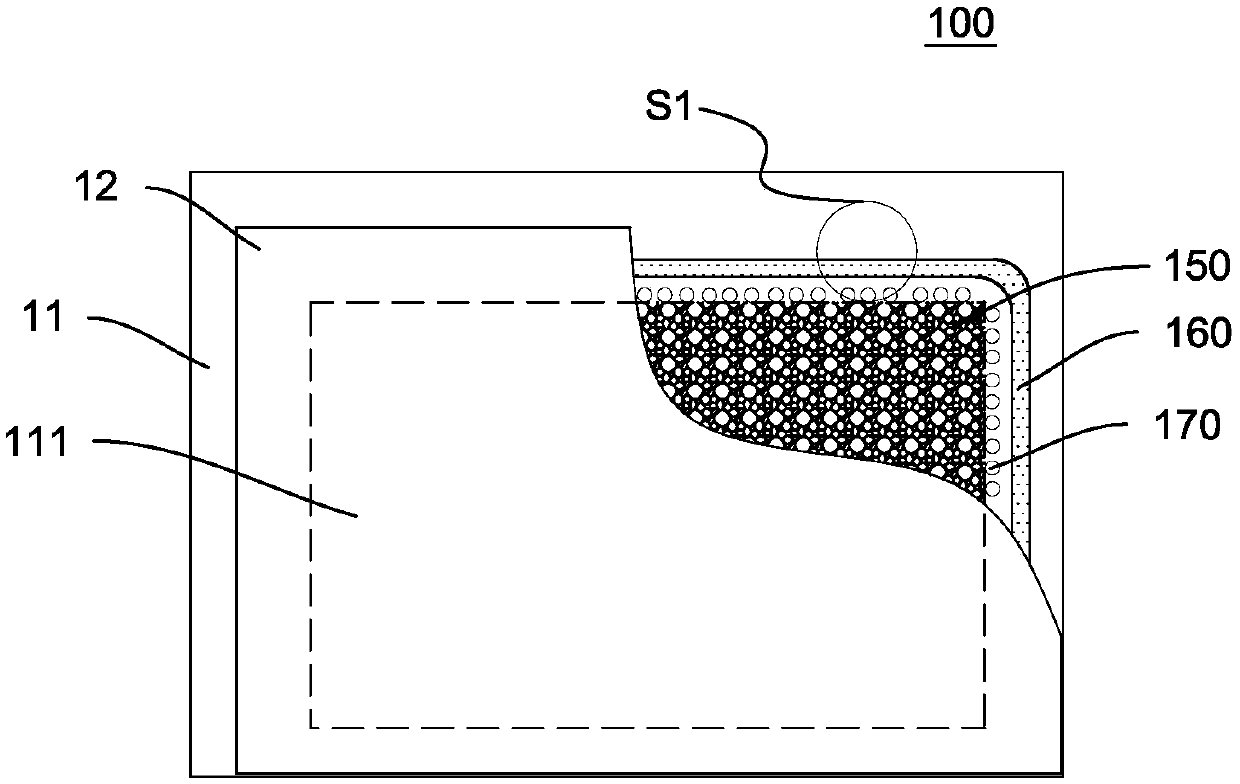

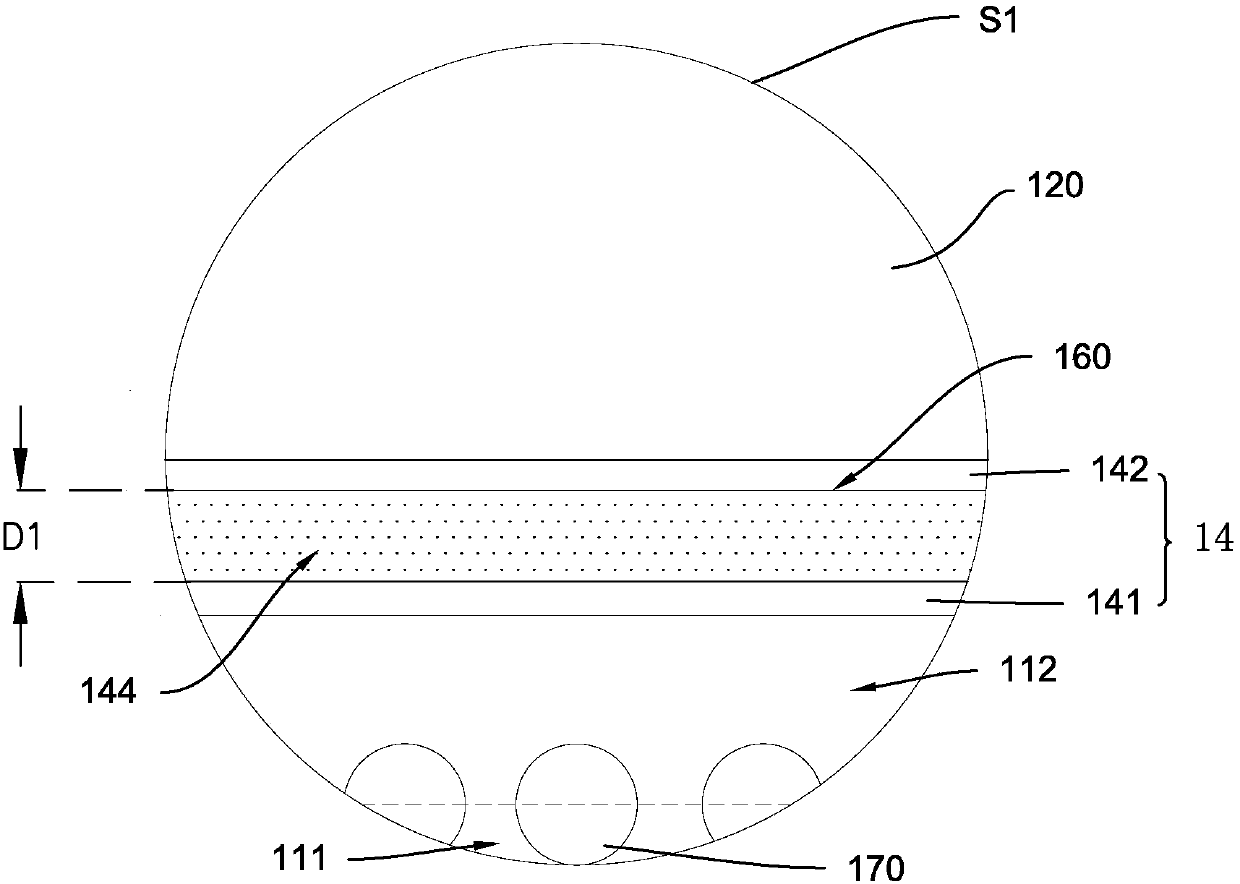

[0033] In an embodiment of the present disclosure, such as Figure 1a As shown, the liquid crystal display panel 100 includes a first substrate 11, a second substrate 12, and a liquid crystal layer 15 and a sealant 160 disposed between the first substrate 11 and the second substrate 12. Wherein, the sealant 160 is arranged around the liquid crystal layer 15 for bonding the first substrate 11 and the second substrate 12, and at the same time, the liquid crystal layer 15 is enclosed by the sealant 160 and the In a sealed space 151 enclosed by the first substrate 11 and the second substrate 12. In order to provide a supporting force between the first substrate 11 and the second substrate 12, a spacer 170 is further provided in the sealed space 151.

[0034] The projection of the liquid crystal layer 15 on the first substrate 11 or the second substrate 12 can be defined as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com