Battery bin anti-collision beam topological optimization method based on equivalent static load method

A topology optimization and static load technology, applied in the field of mechanical equipment design, can solve problems such as large randomness, and achieve the effect of improving optimization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

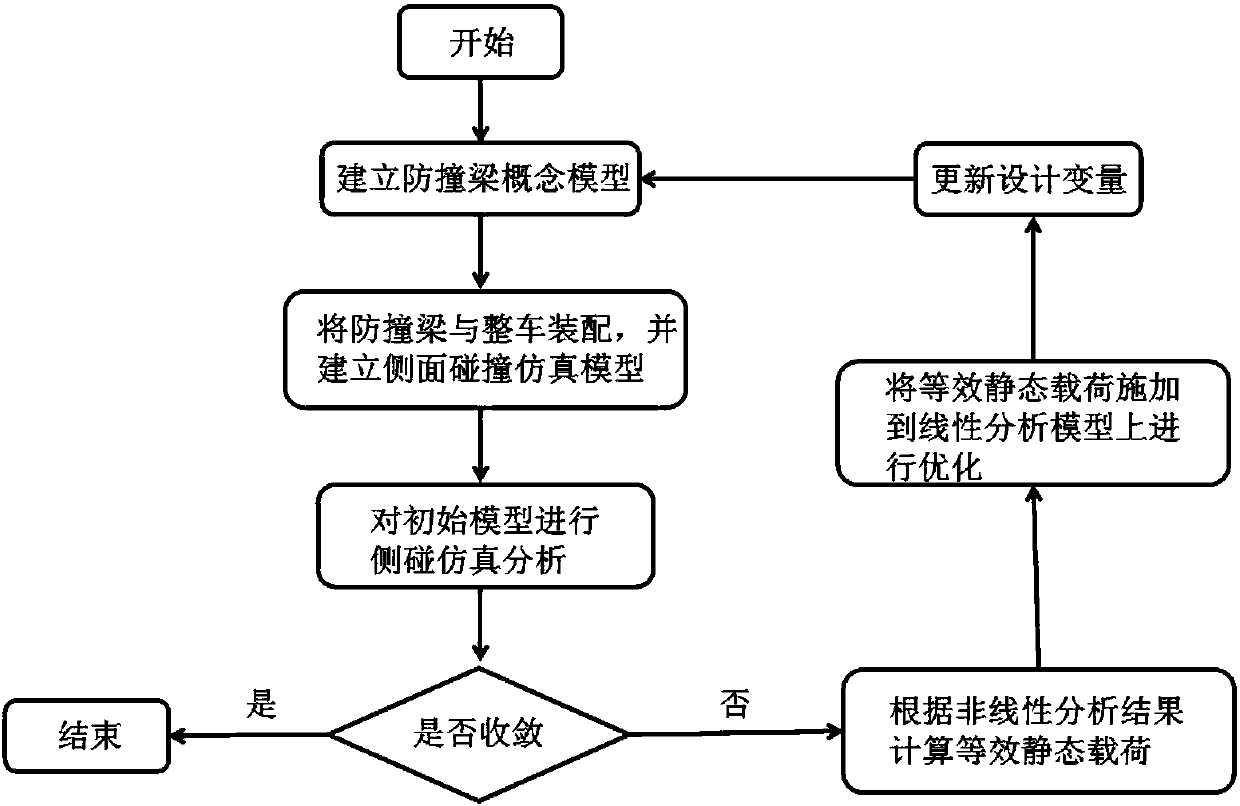

[0025] The core of the present invention is to provide a battery compartment anti-collision beam topology optimization method based on the equivalent static load method, specify the time step of the equivalent static load extraction point, take the mass of the anti-collision beam as the objective function, and use the displacement as a constraint. The continuous iterative optimization process finally obtains the optimal anti-collision beam structure form. In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings.

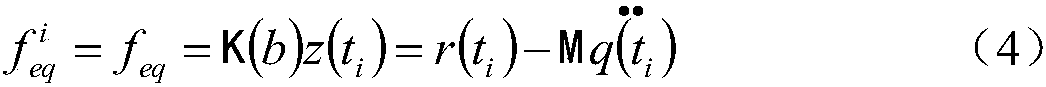

[0026] The invention obtains the dynamic load of the anti-collision beam by simulating the side collision working condition of the anti-collision beam of the battery compartment, and calculates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com