Method for prolonging service life of lead-acid storage battery or battery pack

A technology for lead-acid storage batteries and battery packs, applied in secondary battery charging/discharging, secondary battery repair/maintenance, electrolyte/reactant regeneration, etc., can solve early capacity loss, poor contact between active material and conductive current collector, Negative specific surface area shrinkage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

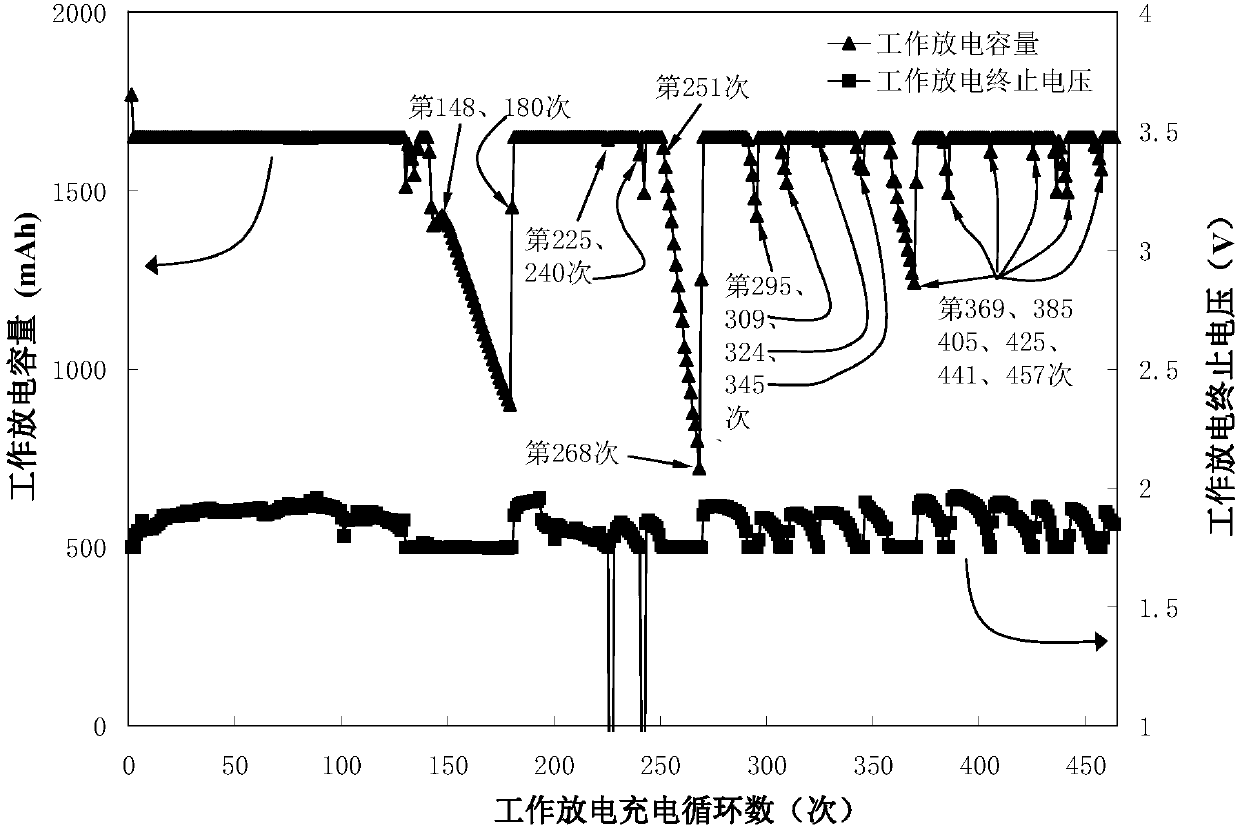

[0076] The lead-acid storage battery of this embodiment is a planar grid-type lead-acid storage battery with a rated capacity of 2.32Ah (2h rate, 25°C) and a rated voltage of 2V. Charge with constant current at a rate of 0.2 (rated capacity, the same below), when the voltage reaches 2.65V, charge at a constant voltage of 2.65V, the total time for two charges is 6 hours and 24 minutes, and then charge at a rate of 2h, 80% DOD ( depth of discharge) after discharging, repeat the above charging and discharging process, that is, work through the above charging and discharging cycle, and the working environment temperature is 25±1°C. During the cycle charge and discharge operation and polarity reversal of the battery in this embodiment and the subsequent charge or charge and discharge operation, factors such as fluid loss, open circuit, short circuit, mechanical damage, and test failure are eliminated or prevented. result interference.

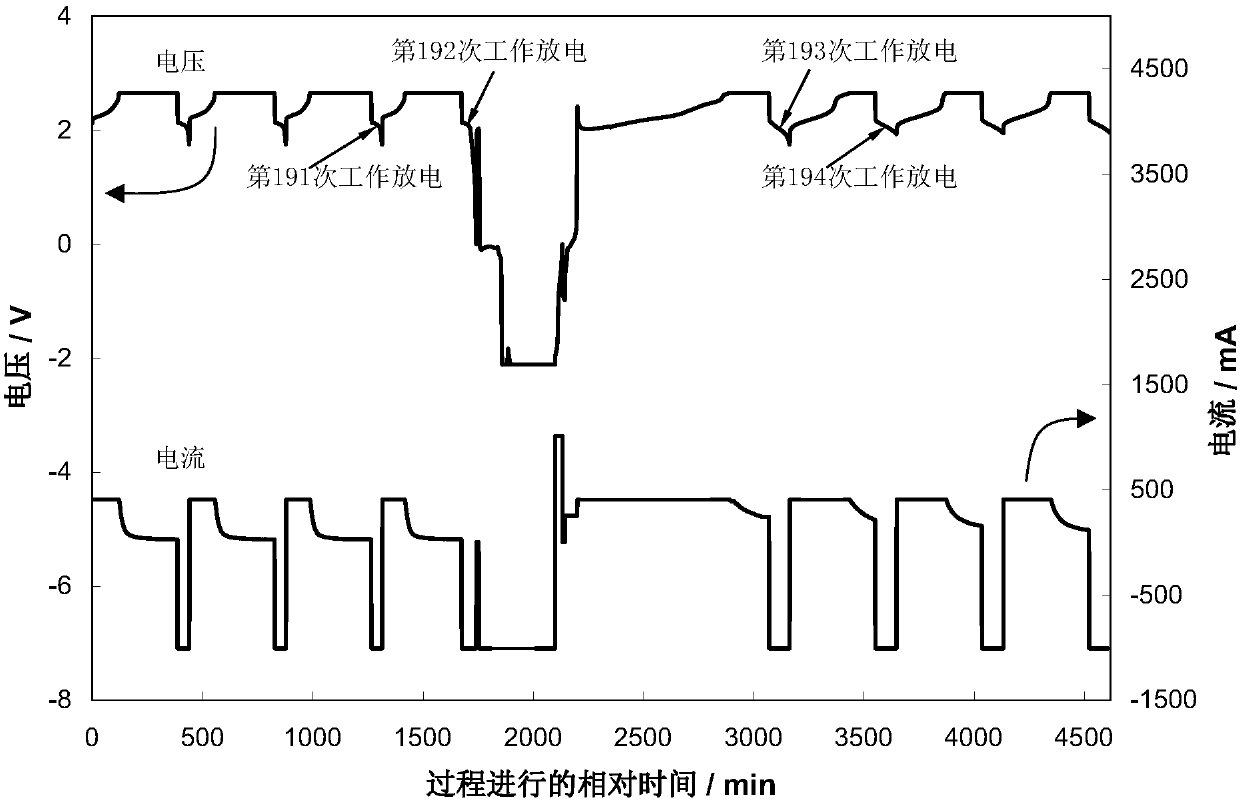

[0077] When the remaining capacity of the le...

Embodiment 2

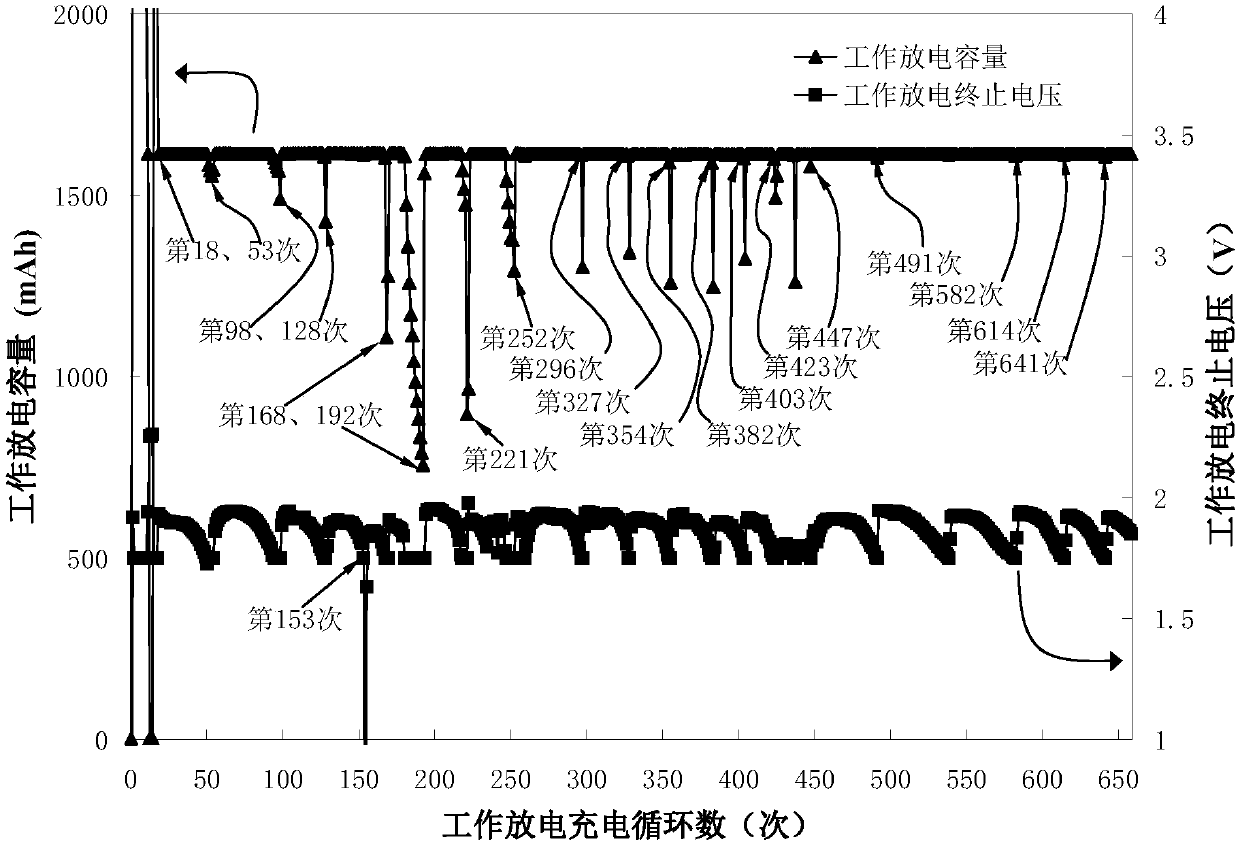

[0108]The method for improving or prolonging the service life of the lead-acid storage battery or battery pack in this embodiment is that when the lead-acid storage battery or battery pack in this embodiment softens or / and falls off due to positive active material, negative electrode specific surface area shrinks, electrode passivation, corrosion, early One or more failure modes or problems of capacity loss, sulfation, poor contact between active material and current collector, resulting in a decrease in the working discharge capacity of the cell or battery pack, or when it is necessary to prevent or mitigate the above seven failure modes Or when the problem damages the working ability of the lead-acid battery or battery pack, or when the work of the lead-acid battery or battery pack in this embodiment reaches a certain number of cycles or float charging time, the positive and negative poles of the lead-acid battery or battery pack in this embodiment Carry out the following pol...

Embodiment 3

[0112] The implementation steps and operations of carrying out the polarity reversal of the present invention and the subsequent charging or charging and discharging operations of the lead-acid battery pack (rated capacity of 2h rate is 2Ah, rated voltage is 4V, 25°C) in this embodiment are the same as the present invention The steps and operations implemented on the battery in Invention Example 1 are basically the same, the difference is that in the operation of this example, the polarity reversal and the subsequent charging or discharging operation are applied to the positive electrode of the lead-acid battery pack and negative pole.

[0113] In other implementations of this embodiment, the charging stop voltage after each polarity reversal is 3.0V or 4.5V.

[0114] In other implementations of this embodiment, the polarity reversal and subsequent charging or charging and discharging operations of the present invention can also be performed on a single battery or some single ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com