Rotary immersed type filtering device

A technology of filtering device and rotating device, which is applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve problems such as energy loss, and achieve the effect of reducing energy consumption and improving flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

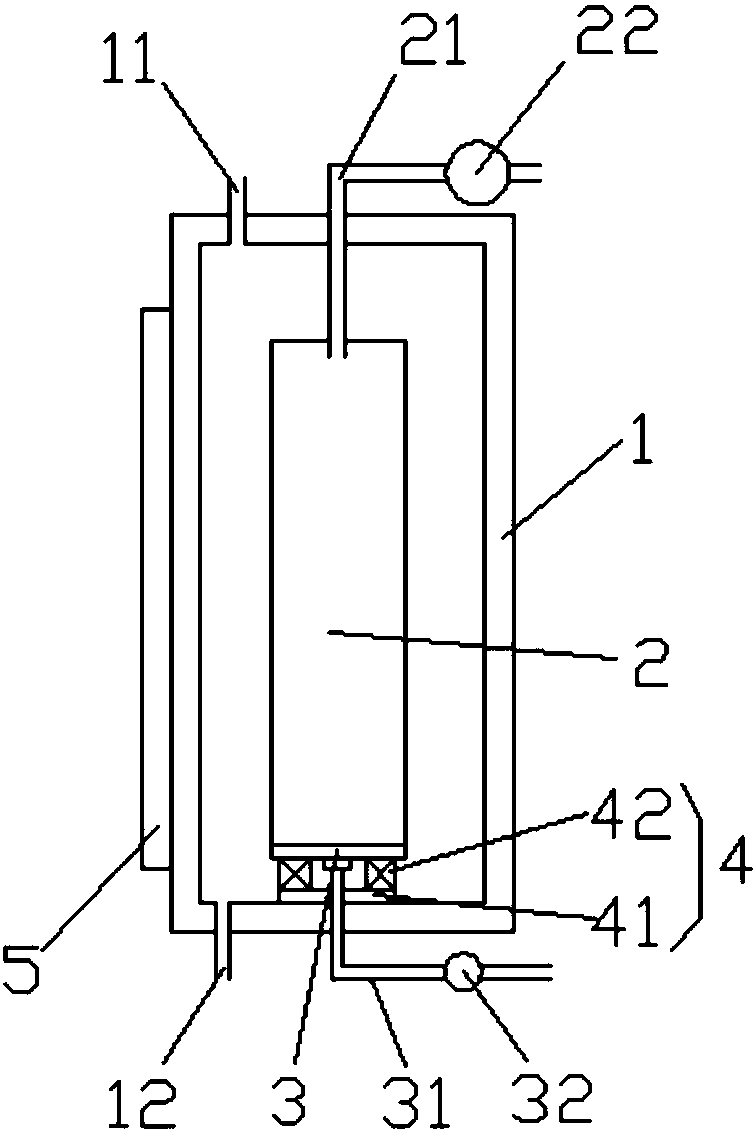

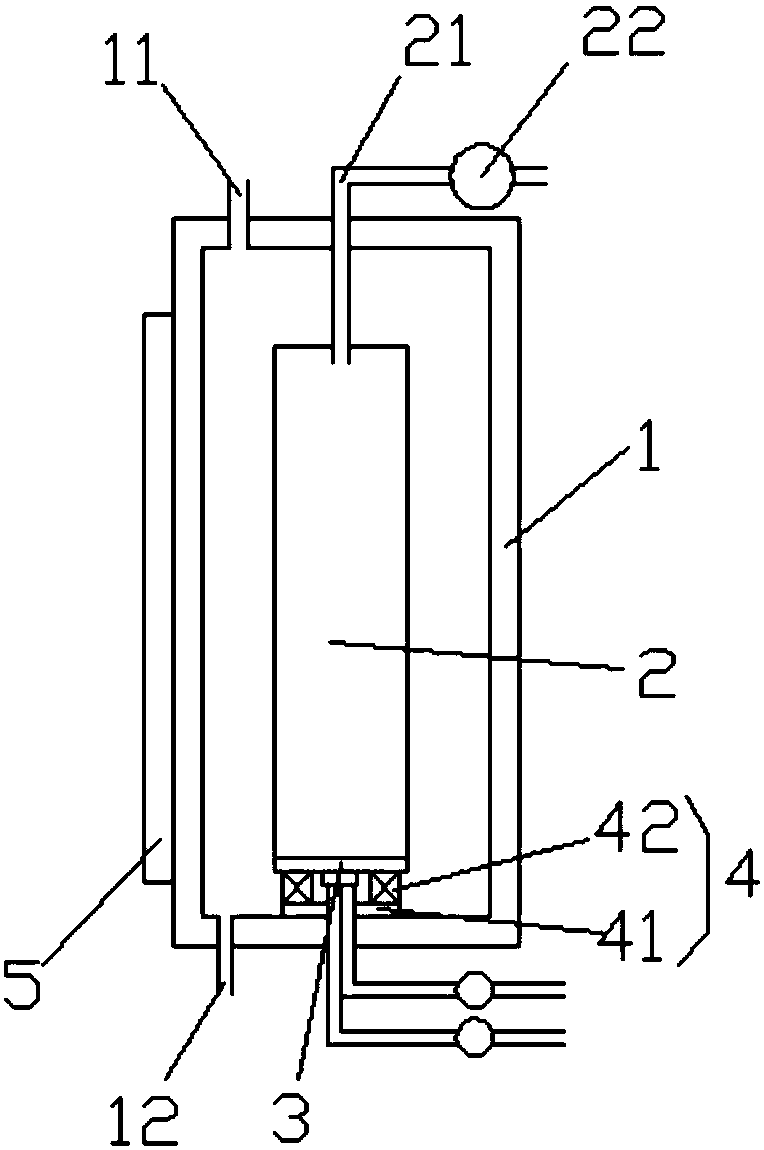

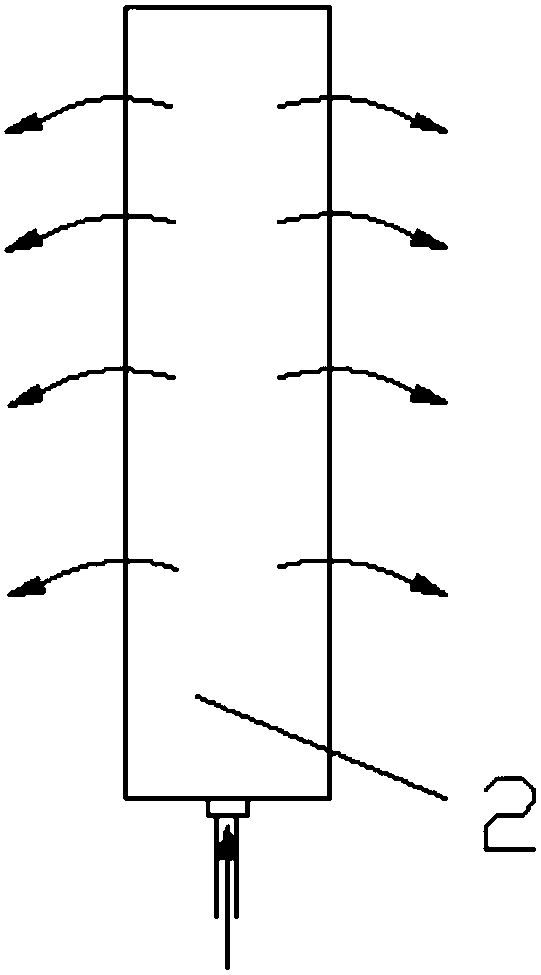

[0037] figure 1 is a schematic device diagram of a rotatable submerged filter device according to an embodiment of the present invention. like figure 1 As shown, the rotatable submerged filter device may generally include a water storage tank 1 , a membrane module filter unit 2 , a flushing unit 3 and a rotating device 4 . The water storage tank 1 has an accommodating space. The top of the water storage tank 1 is provided with an air valve 11 and the bottom is provided with a waste discharge valve 12 . The membrane module filter unit 2 is rotatably arranged inside the water storage tank 1 and connected to the water outlet pipeline 21 for separating solid particles in the liquid. The flushing unit 3 is arranged inside the water storage tank 1 and is used for flushing the filter unit 2 of the membrane module. The rotating device 4 is installed on the top or bottom of the membrane module filtering unit 2, and is used to drive the membrane module filtering unit 2 to rotate, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com