An adjustable punching module applied to a mold

An adjustable, mold technology, applied in the direction of forming tools, manufacturing tools, perforation tools, etc., can solve the problems of troublesome installation, high cost, long disassembly time, etc., and achieve the effect of cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

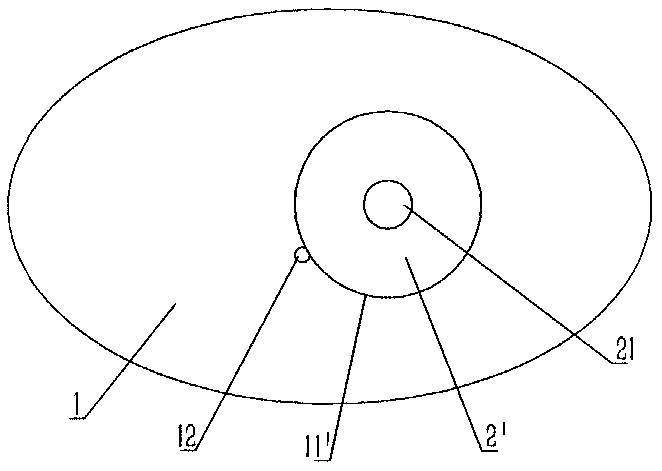

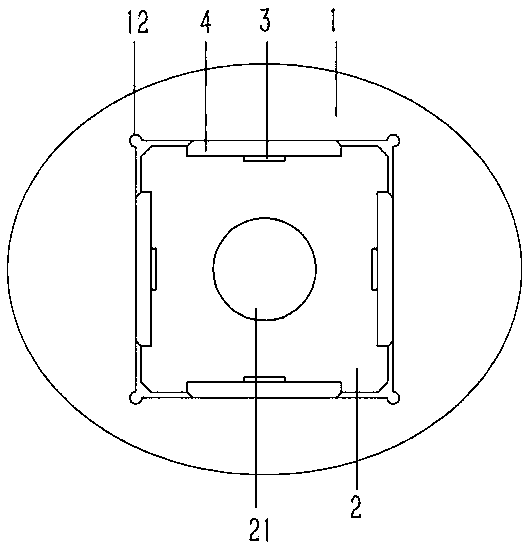

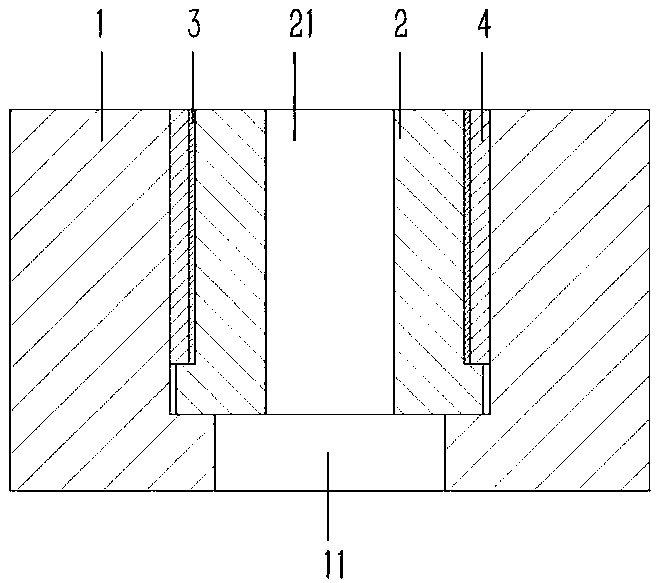

[0017] Example: see Figure 2 to 4 As shown, an adjustable punching module applied to a mold includes a base plate 1 of the mold. A rectangular stepped hole 11 is formed on the base plate 1, and a rectangular embedded module 2 is inserted into the stepped hole 11 of the base plate 1. The center of the module 2 is formed with a punching hole 21, the four corners of the stepped hole 11 of the substrate 1 are formed with arc-shaped grooves 12, the side wall of the embedded module 2 is formed with a rectangular recess 22, and the bottom surface of the recess 22 is formed with In the card slot 23, the permanent magnet block 3 is inserted and fixed in the card slot 23 of the embedded module 2, and the adjusting washer 4 is inserted in the recess 22 of the embedded module 2, and the two end surfaces of the adjusting gasket 4 respectively abut It leans on the inner wall of the stepped hole 11 of the base plate 1 of the embedded module 2 and the bottom surface of the recess 22 of the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com