Patents

Literature

47results about How to "No need to scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile anti-pinch strip

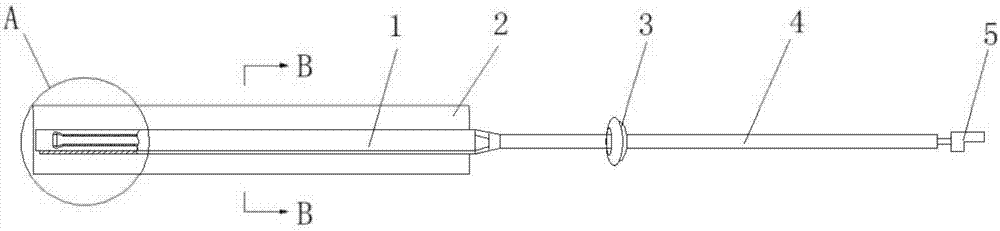

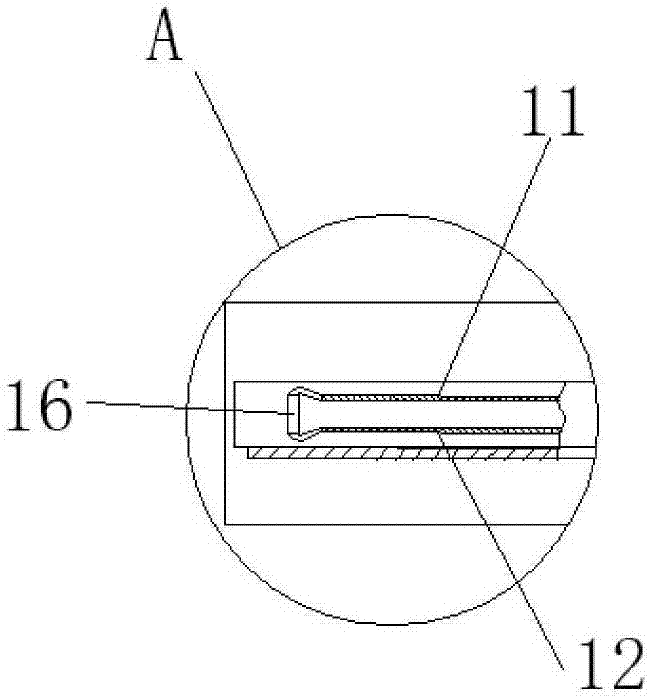

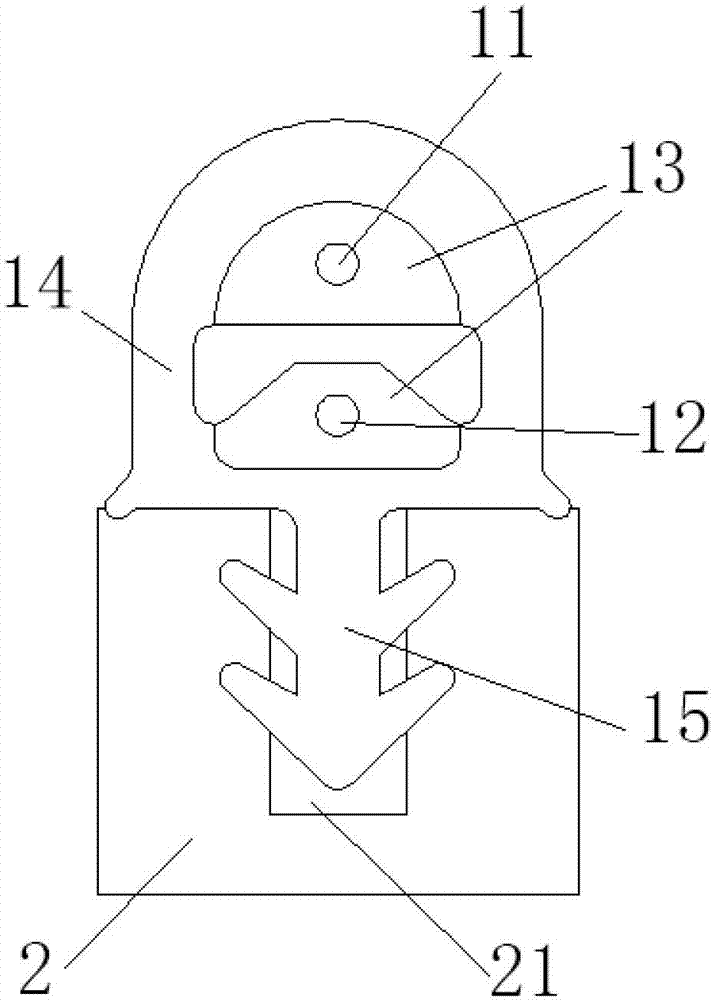

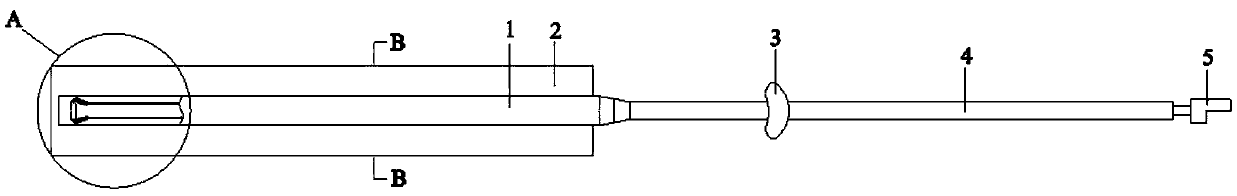

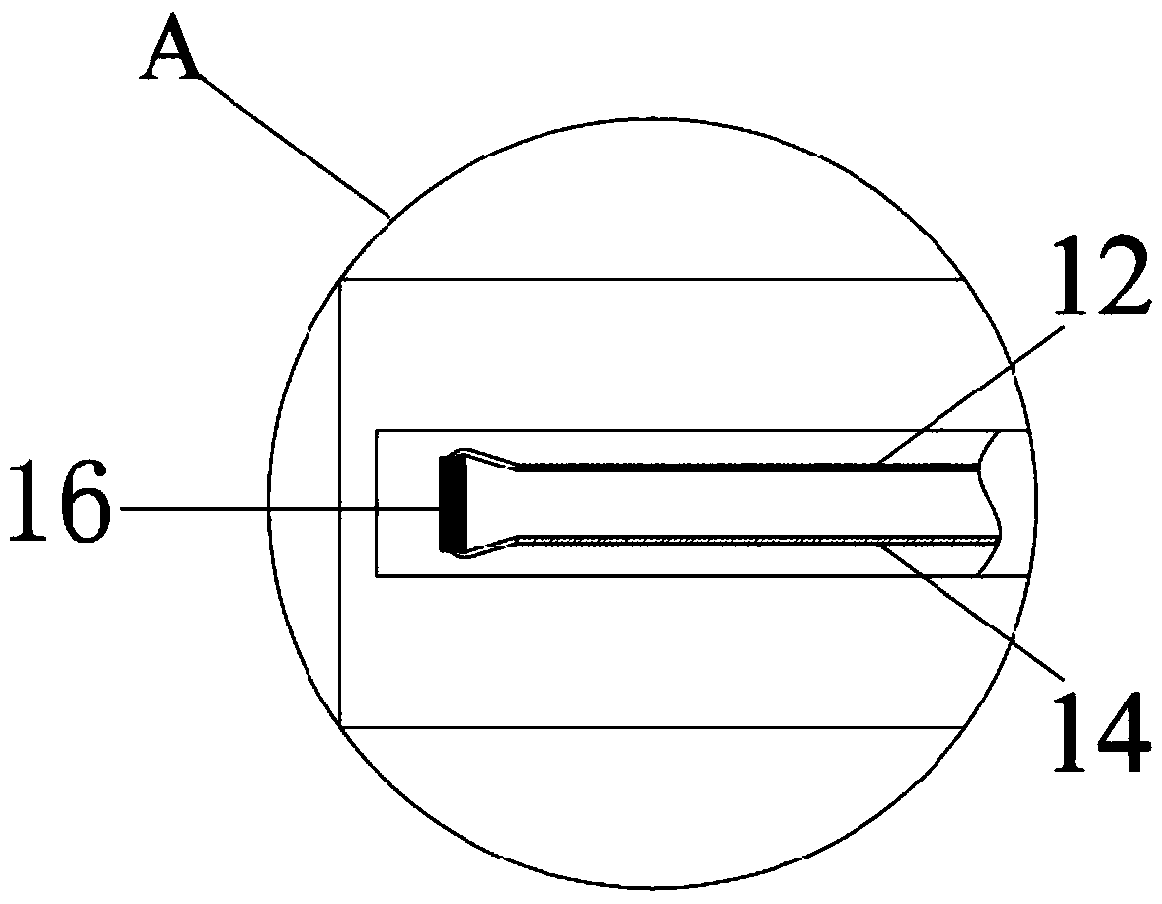

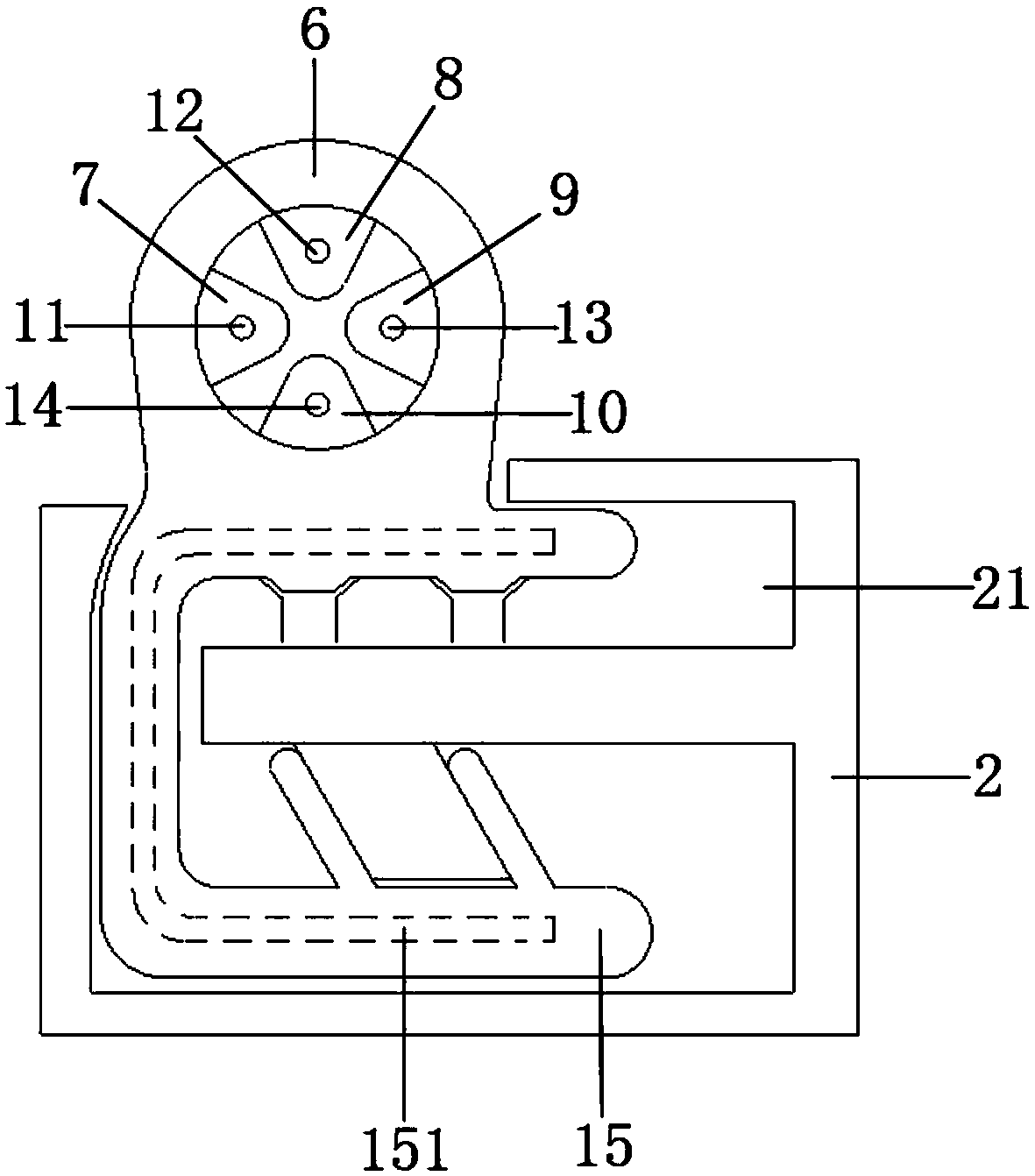

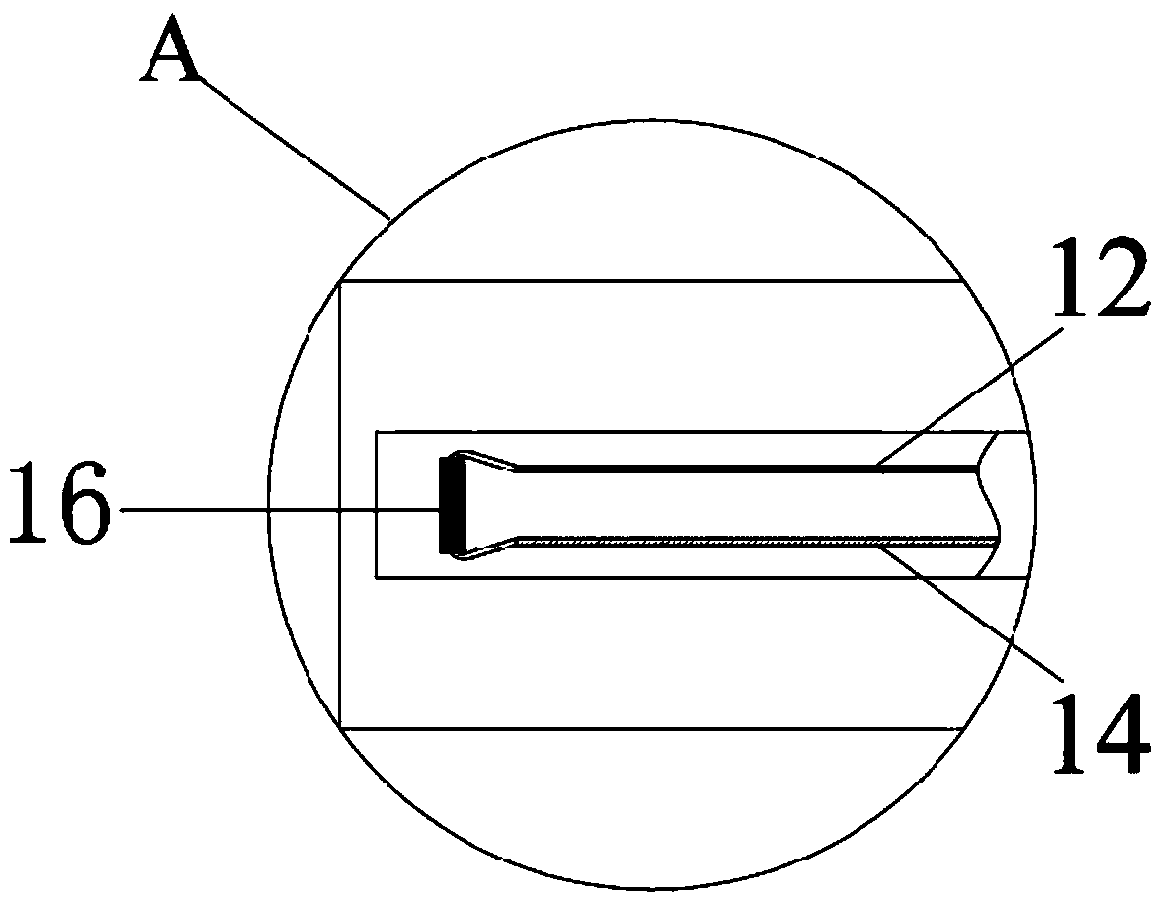

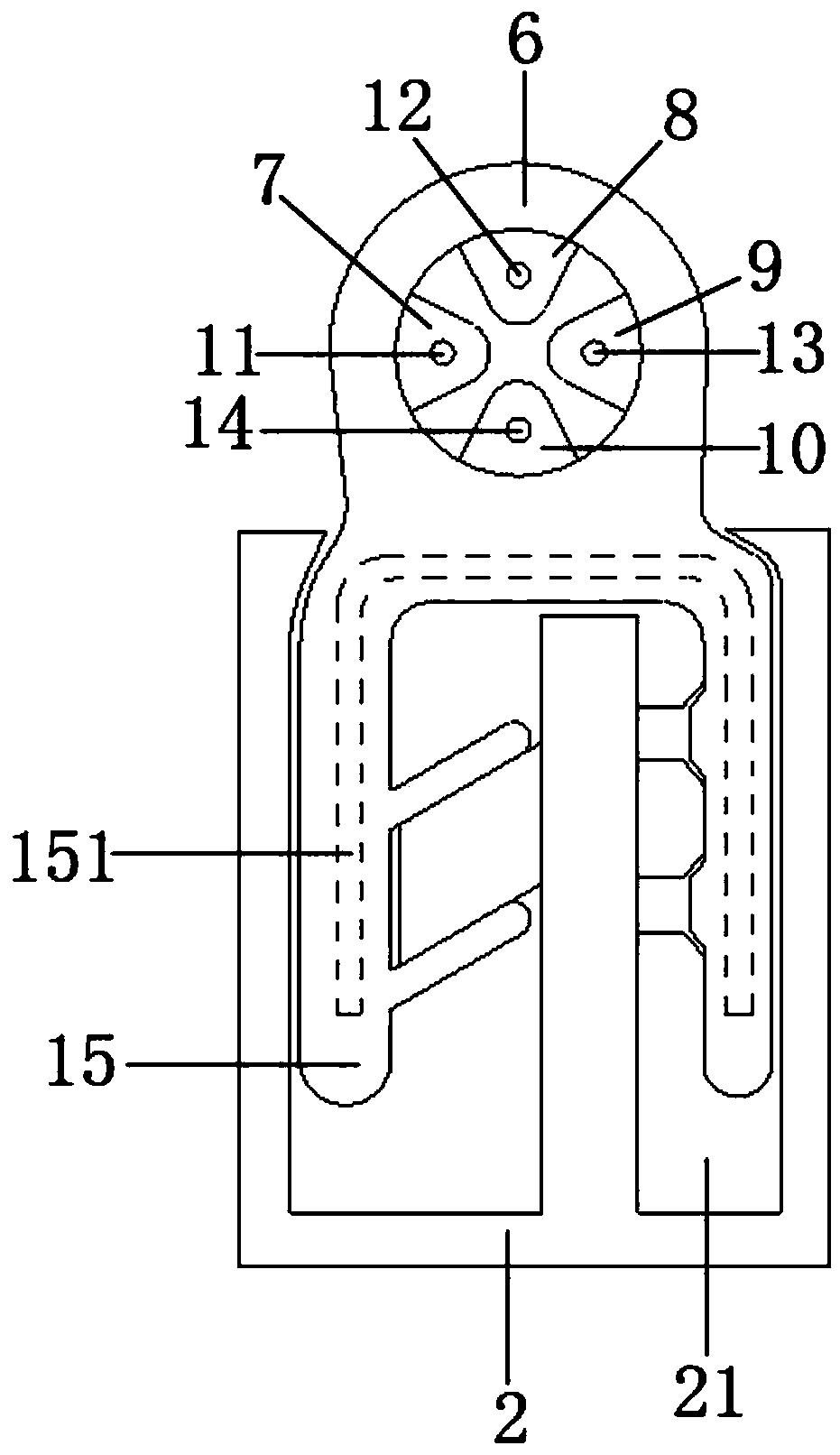

The invention relates to an automobile anti-pinch strip. The automobile anti-pinch strip is provided with an anti-pinch strip body, a fixing support, a sealing fixing device, a wire, a wire connector and an anti-pinch controller. The anti-pinch strip body is provided with a first wire, a second wire, an electric conductor, an insulator, an assembling part and a resistor. The automobile anti-pinch strip has the beneficial effects that the structure is simple, cost is low, and installation is convenient; the response speed is high, and reliability is high; the anti-pinch controller is connected with an automobile center controller, and operation is convenient; when the anti-pinch strip body and the fixing support are assembled, adhesive tape does not need to be used, and cost is reduced; and components of the anti-pinch strip can be replaced, integral scrapping is not needed, and the using cost is reduced; and the assembling part is embedded in the fixing support, and the anti-pinch strip can be prevented from easily disengaging.

Owner:SHANGHAI RONGNAN TECH CO LTD +2

Automobile anti-clamping device being good in safety and convenient to mount

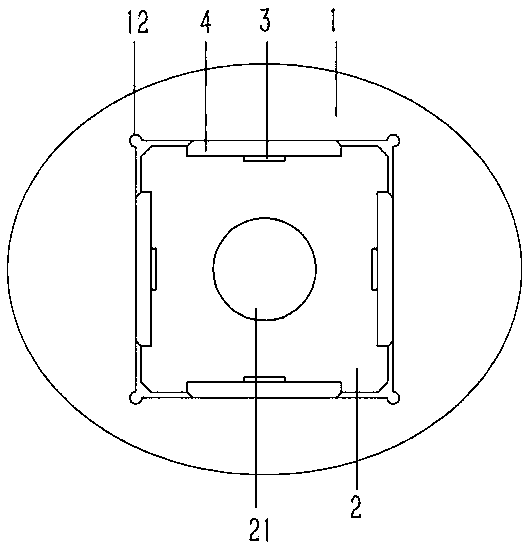

PendingCN108705924ASimple structureEasy to installPower-operated mechanismSignalling/lighting devicesElectricityResistor

The invention relates to an automobile anti-clamping device being good in safety and convenient to mount. The automobile anti-clamping device comprises an anti-clamping strip body, a fixing bracket, asealing cover, a connecting wire, a wire interface and an anti-clamping controller; the anti-clamping strip body is a hollow insulating rubber body, the inner surface of the insulating rubber body isprovided with a first conductive body, a second conductive body, a third conductive body and a fourth conductive body, and a wire is arranged in each conductive body; the four conductive bodies are arrayed on the inner surface of the insulating rubber body in the circumferential direction at equal distances, and gaps are reserved between the conductive bodies; and an assembling part is arranged on the lower portion of the insulating rubber body, a resistor is arranged at the end of the anti-clamping strip body, and the two ends of the resistor are electrically connected with the wires correspondingly. The automobile anti-clamping device has the advantages that the structure is simple, the sensitivity is high, and the cost is low; and the technical problem that an anti-clamping module is low in sensitivity and cannot detect the obstacle state is solved, the situation that the conductive body part is abraded or oxidized and consequently the sensitivity is decreased or even out of orderis avoided, and using safety is improved.

Owner:WUHAN YINAN RUBBER & PLASTIC TECH CO LTD

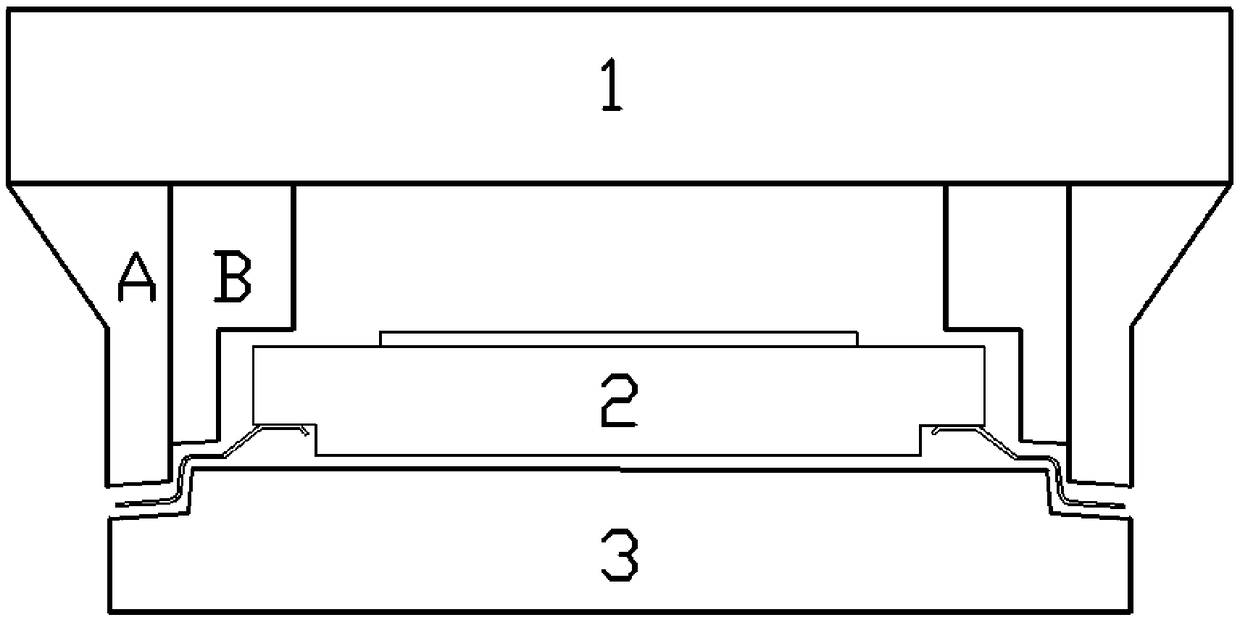

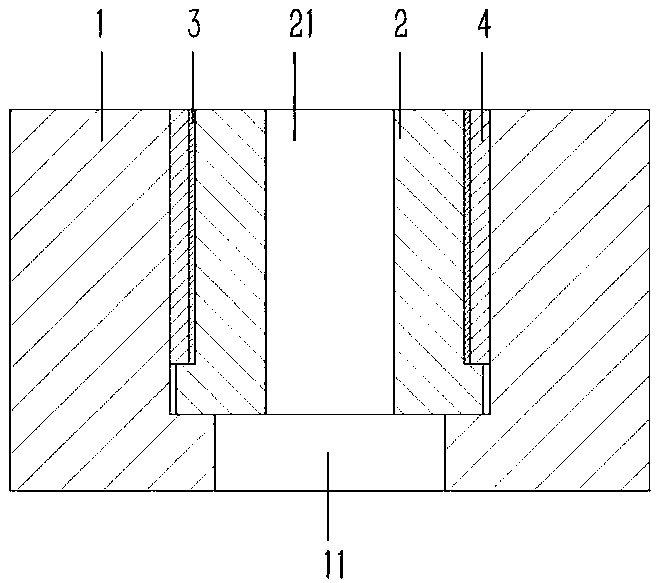

removable mold

InactiveCN102274889ASimple structureEasy to assemble and disassembleShaping toolsPerforating toolsPunchingBiomedical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

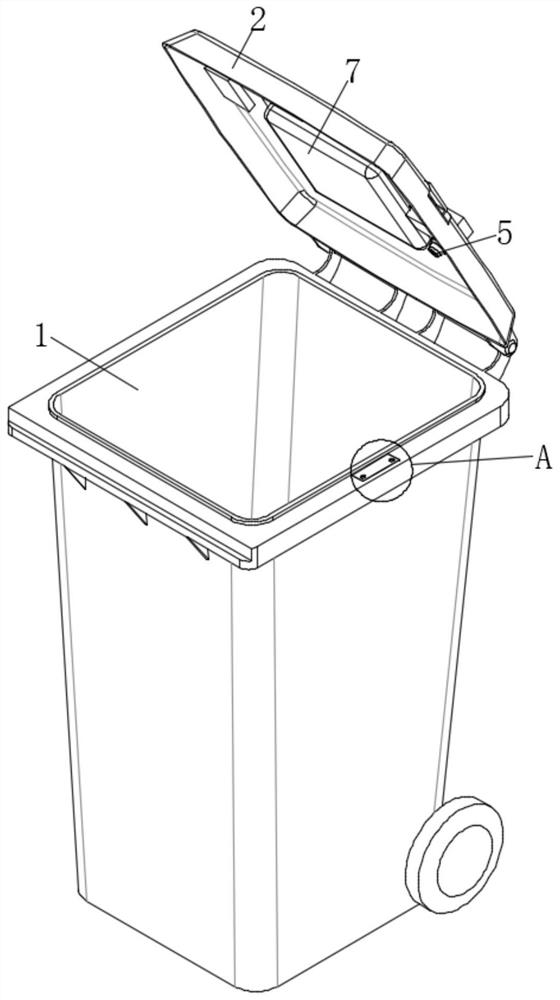

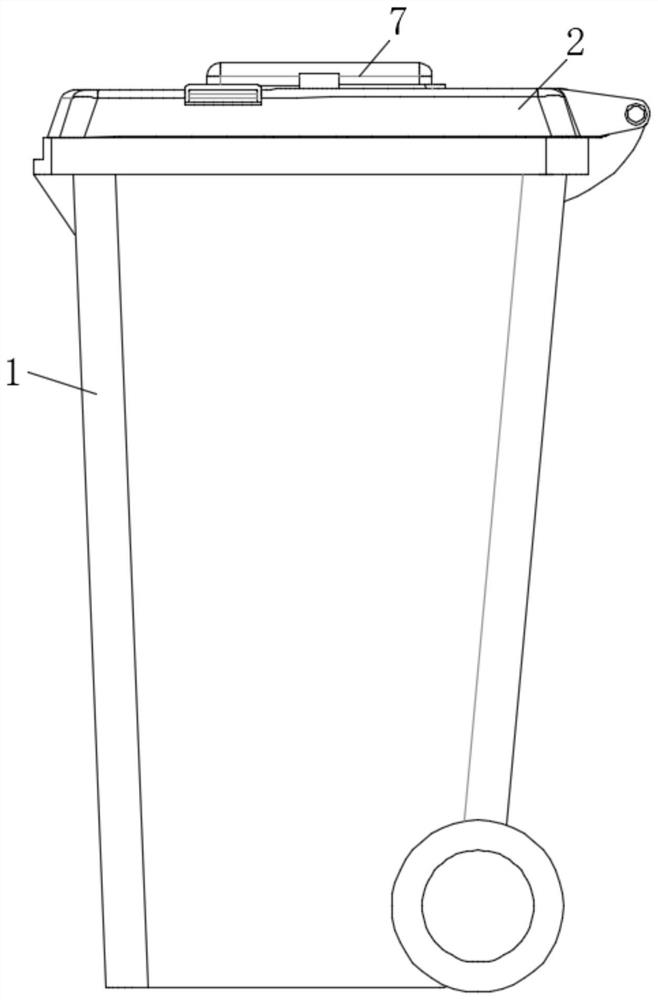

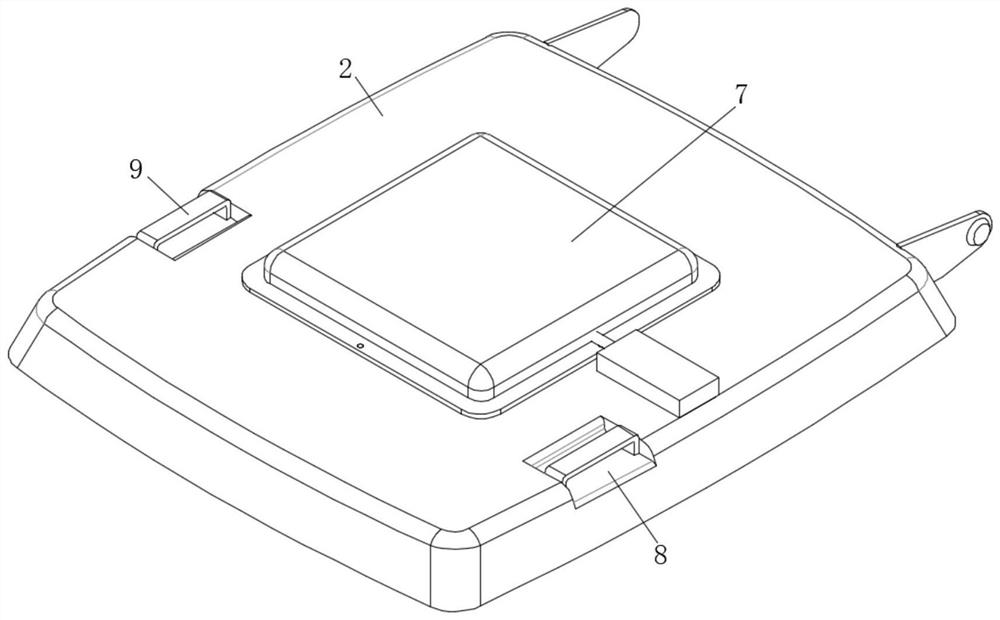

Ultraviolet disinfecting garbage can lid

InactiveCN111806933ADoes not affect supporting useLow costWaste collection and transferRefuse receptaclesBacterial virusInfrared

The invention discloses an ultraviolet disinfecting garbage can lid which comprises a garbage can main body and a garbage can lid body; the garbage can lid body is hinged to the top of the garbage canmain body; a solar panel is fixedly connected with the top of the garbage can lid body; an ultraviolet disinfecting lamp is connected with the bottom of the garbage can lid body in an embedded manner; and an infrared ray sensing switch is fixedly mounted at the bottom of the garbage can lid body and is positioned on the right side of the ultraviolet disinfecting lamp. The ultraviolet disinfectinggarbage can lid reduces the cost, does not affect matched application of a garbage truck, is easy to understand in structure and reduces smelly peculiar smell of the garbage can main body; the entireultraviolet disinfecting garbage can lid does not need to scrap when components are broken; ultraviolet disinfection plays a role in restraining bacterial viruses, so that staff exposure hazard is reduced, and waste and hurt to a human body are reduced; unified application facilitates health management of communities and villages; and unified collection and unified disinfection are changed into separated collection and separated disinfection, so that pressure of unified disinfection and viral spreading capacity are reduced.

Owner:SUZHOU AIKATE METAL PROD CO LTD

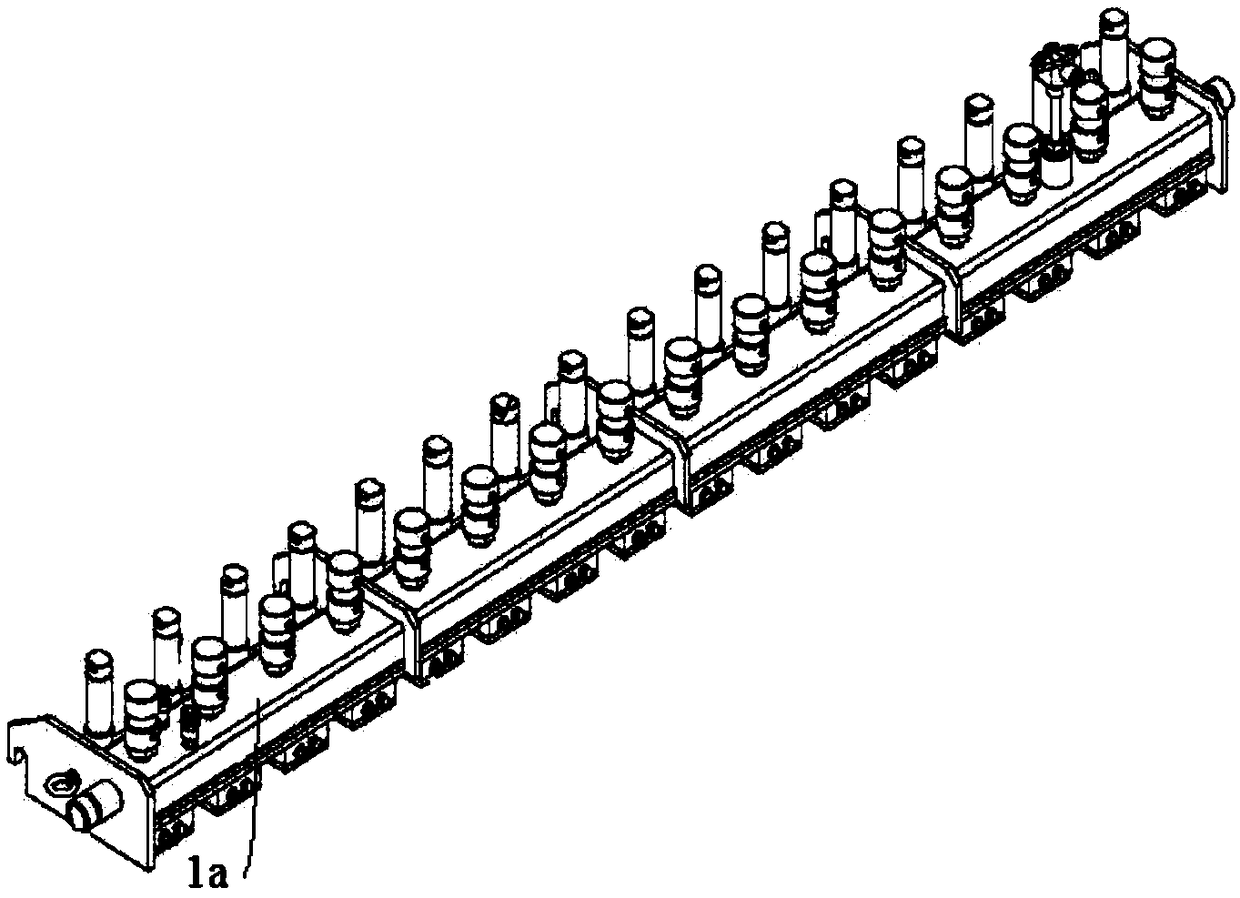

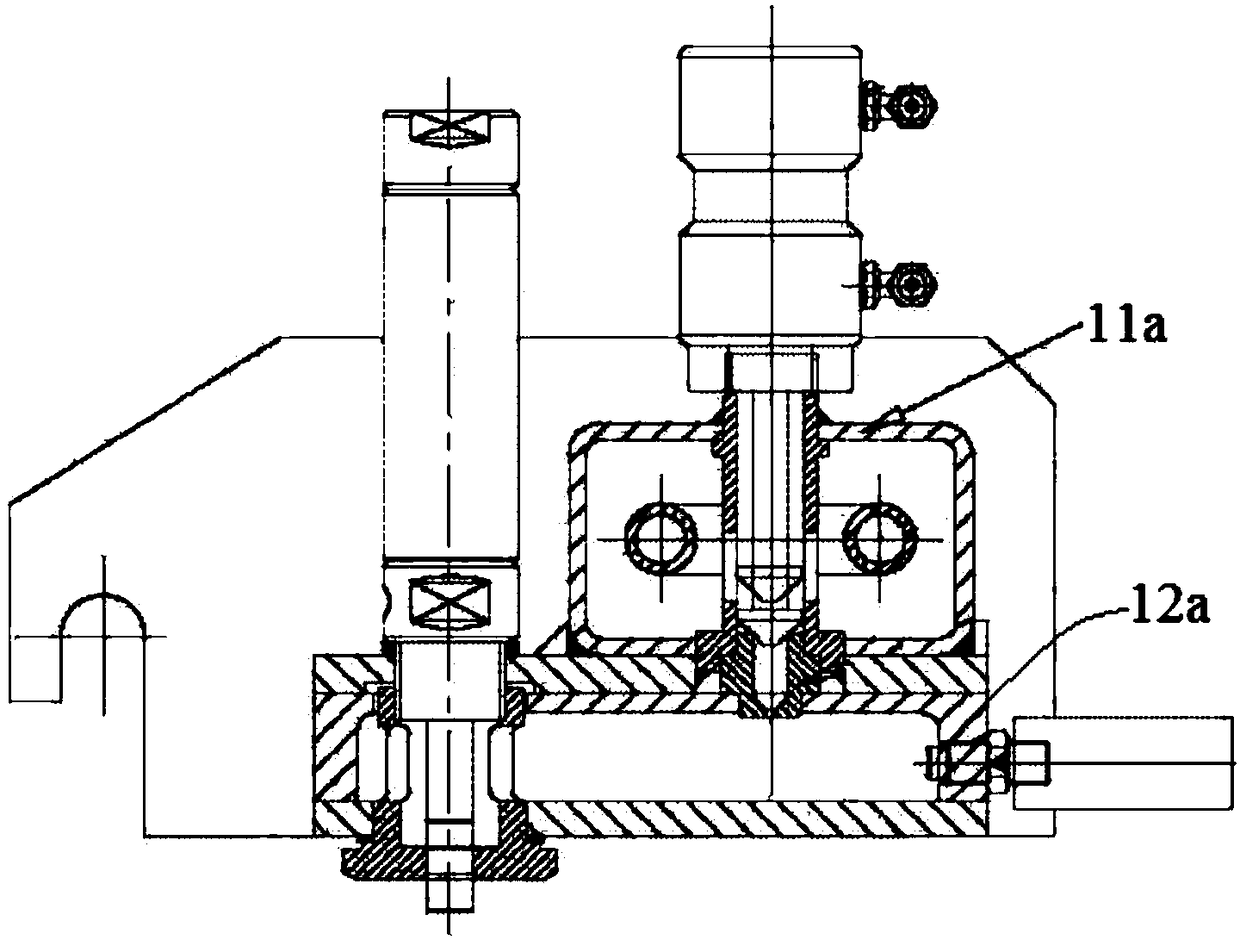

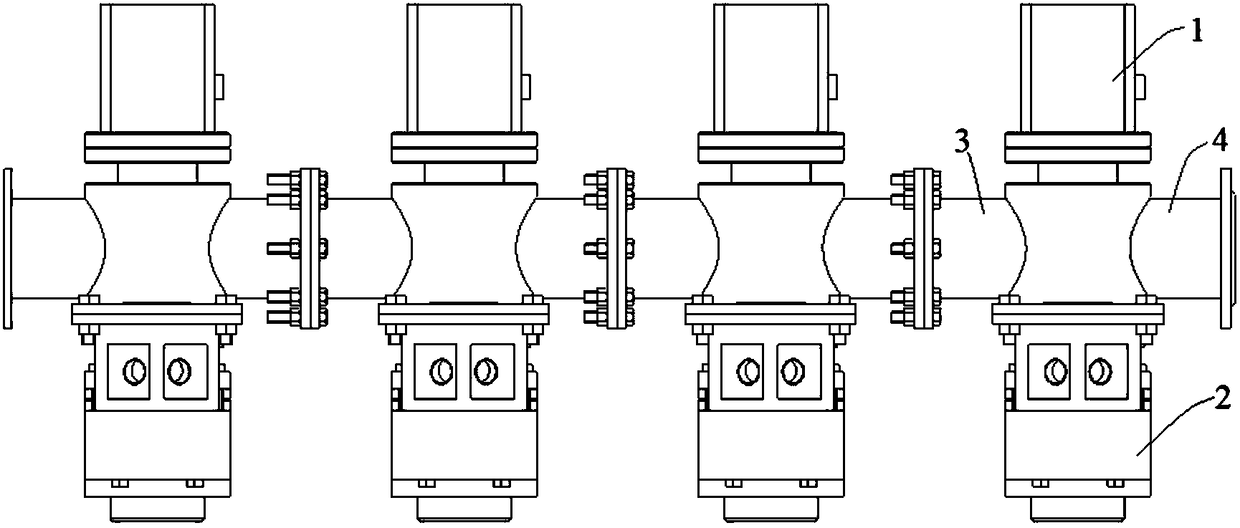

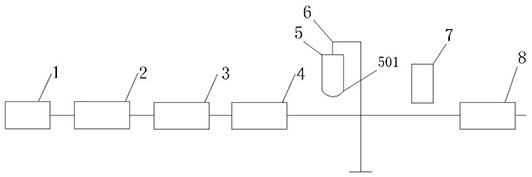

Asphalt foaming spraying apparatus and asphalt cold recycling device

PendingCN108149549ANo need to scrapImprove maintainabilityRoads maintainenceClimate change adaptationEngineeringMechanical engineering

The invention discloses an asphalt foaming spraying apparatus and an asphalt cold recycling device. The asphalt foaming spraying apparatus comprises at least two foaming spraying unit groups which areindependently arranged, wherein two adjacent foaming spraying unit groups in the at least two foaming spraying unit groups are detachably connected with each other. At least two foaming spraying unitgroups of the asphalt foaming spraying apparatus are independently arranged, the adjacent two foaming spraying units are detachably connected with each other, that is, any one foaming spraying unit group in the at least two foaming spraying unit groups is replaceable, so that when one or more foaming spraying unit groups malfunction, the whole asphalt foaming spraying apparatus does not need to be abandoned only by replacing the malfunctioned foaming spraying unit group, and the maintainability of the asphalt foaming spraying apparatus can be improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

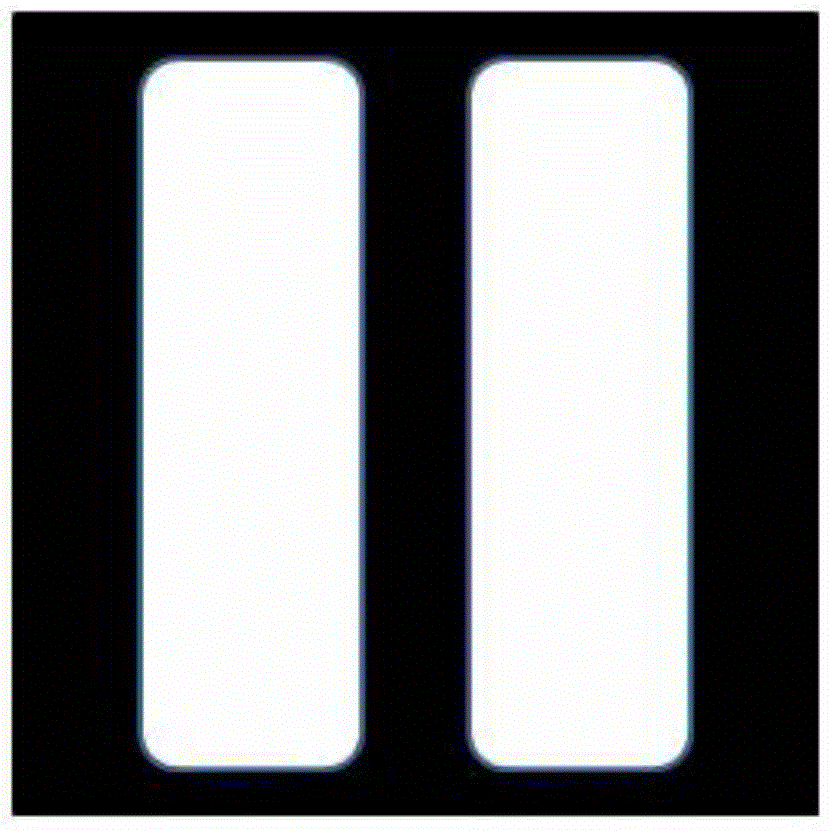

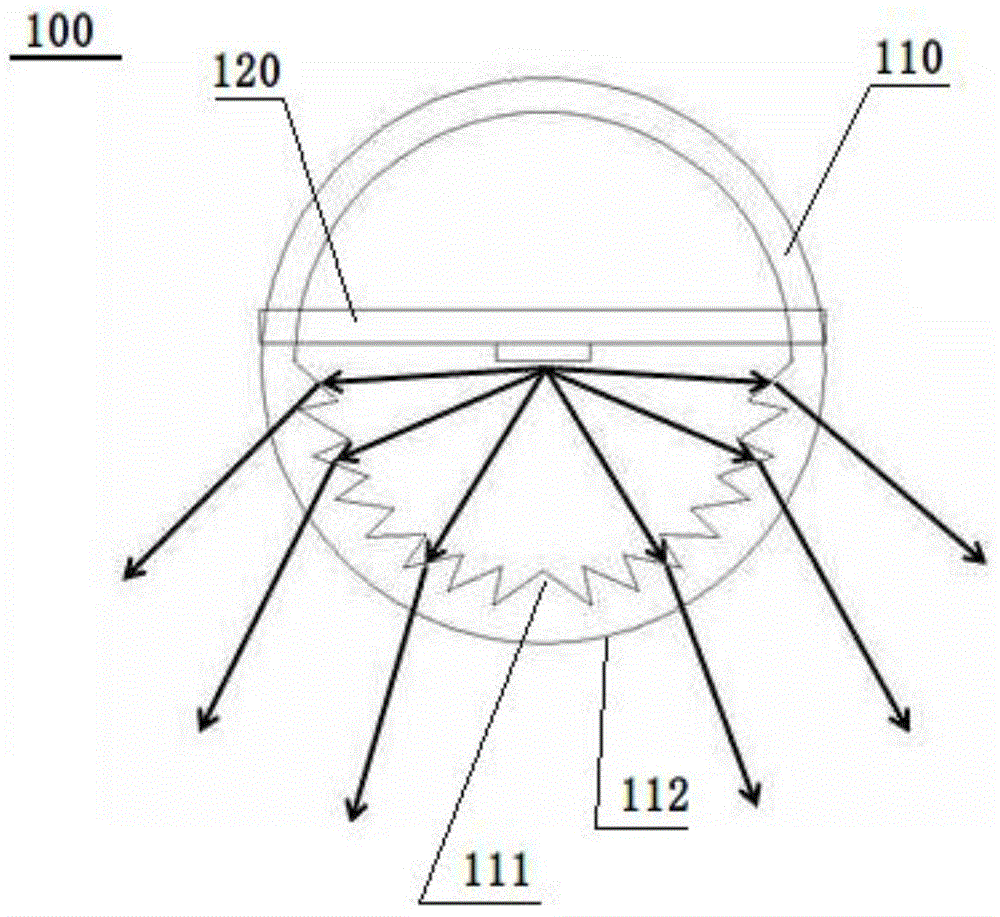

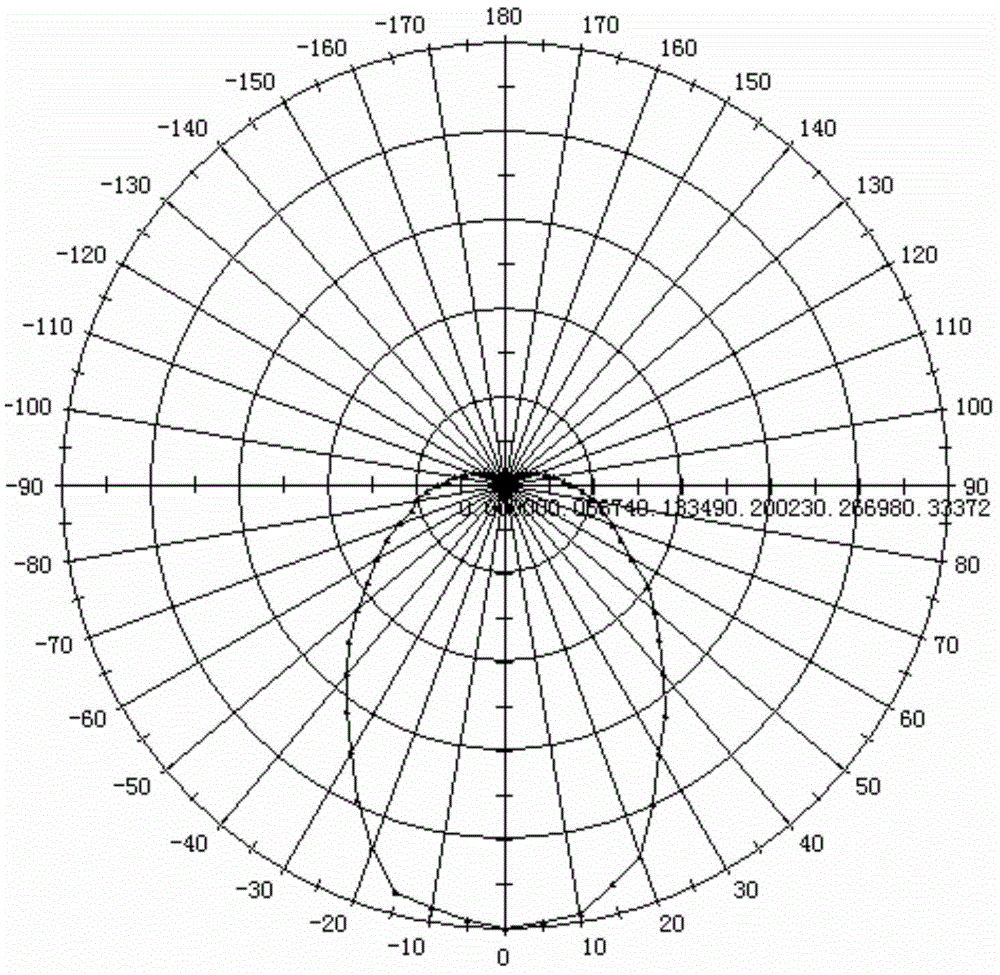

Large-angle light distribution illumination module and ceiling lamp with the same

InactiveCN104791629AImprove light distribution efficiencyNo need to scrapPoint-like light sourceLight fasteningsFluorescenceEngineering

The invention provides a large-angle light distribution illumination module which comprises two LED lamp tubes. Each LED lamp tube comprises a tube body, an LED light source plate arranged in the tube body and an LED light source. A microstructure is arranged on the inner wall of each tube body. The microstructures are arranged at light outlets of the LED light sources, so that out-going light of the light sources is converged through the microstructures. The two LED lamp tubes are parallel and are arranged in a co-plane mode, so that the included angle alpha between two surfaces of the LED light sources arranged on the two LED light source plates in the two LED lamp tubes is between 0 degree and 180 degrees. According to the technical scheme, the LED lamp tubes can be directly used for replacing a fluorescent tube, bright-dark fringes are removed when bat wing light distribution is generated, and brightness is even.

Owner:OPPLE LIGHTING

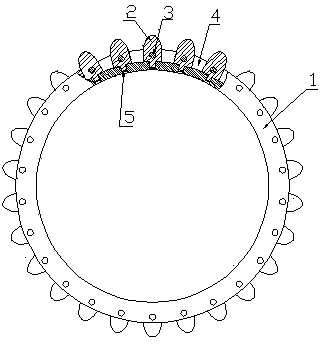

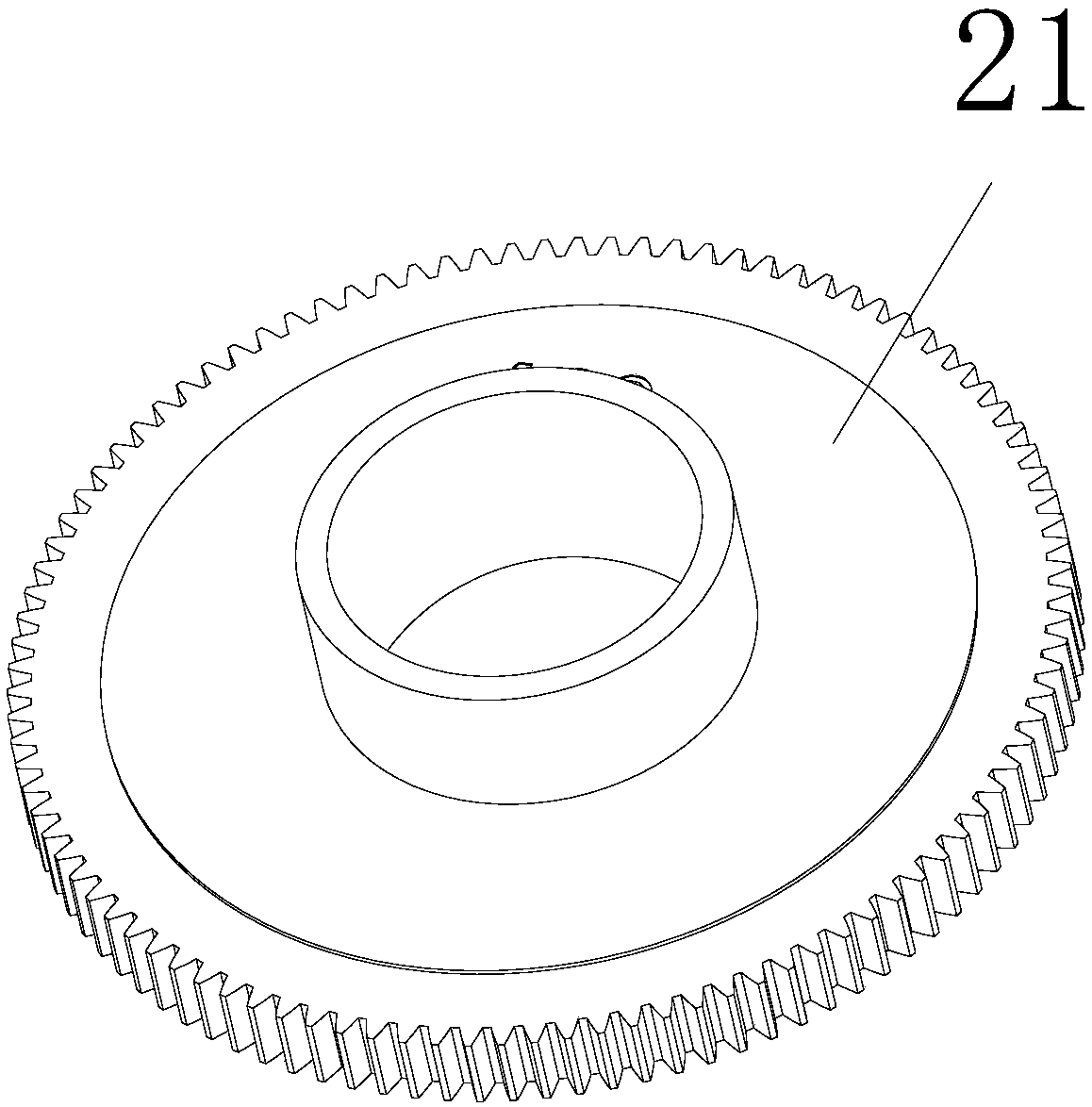

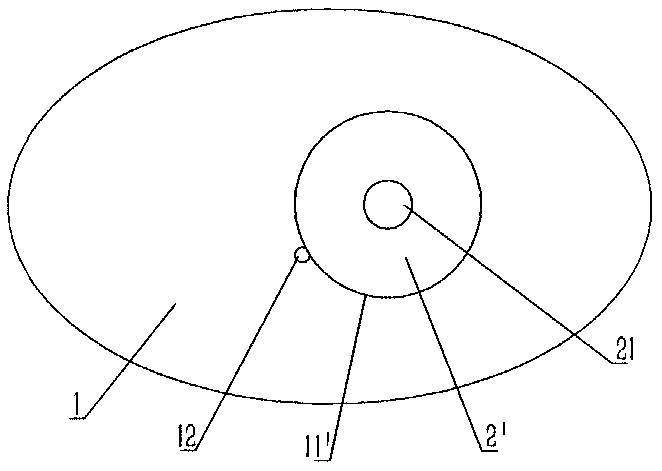

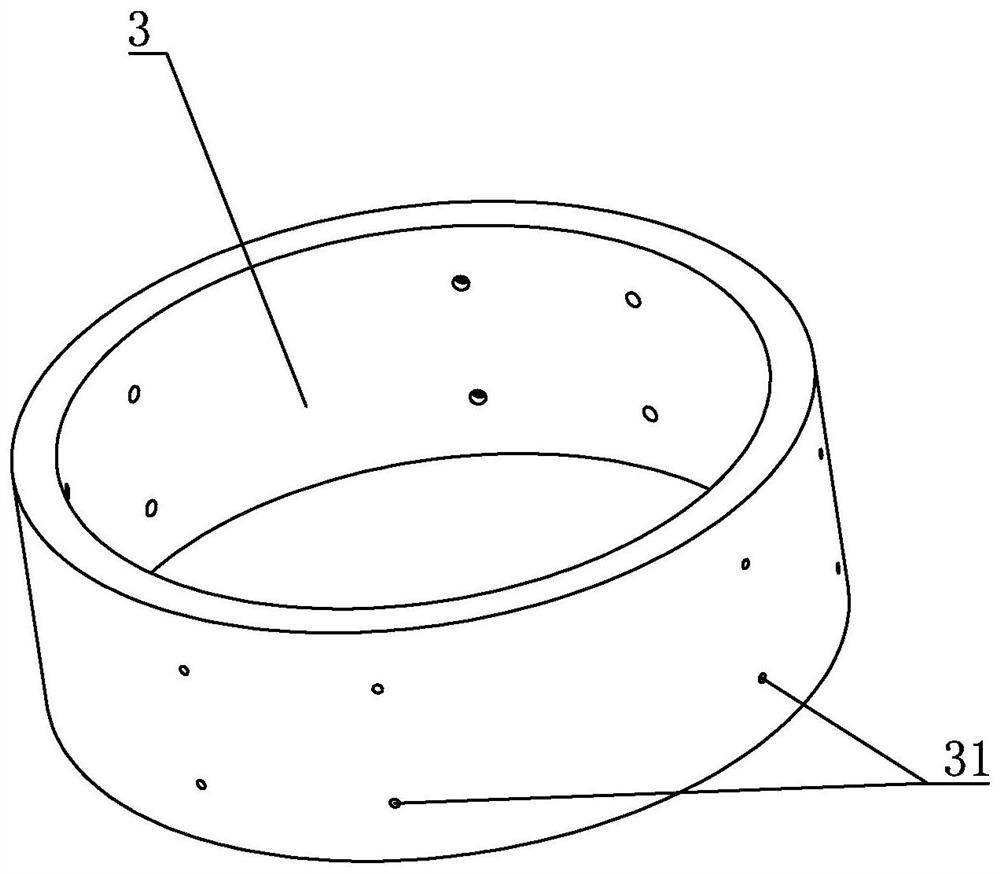

Large gear structure of cement mixer

InactiveCN103775608ANo need to scrapReduce use costPortable liftingGearing elementsGear wheelGear tooth

The invention discloses a large gear structure of a cement mixer. According to the large gear structure of the cement mixer, the teeth and the gear ring of a large gear are separately independent, the bottom of every gear tooth is provided with a boss, the outer circumference of the gear ring is provided with a ring groove, the gear teeth are evenly distributed and embedded into the ring groove of the gear ring, the bottom boss of every gear tooth is fixed with the corresponding hole in the bottom surface of the ring groove, and the gear teeth are fixed with the gear ring through hinge pins. According to the large gear structure of the cement mixer, every gear tooth can be fabricated separately, thereby being simple in fabricating process and meanwhile having the advantage of relatively low cost.

Owner:JIANGSU BADA HEAVY IND MACHINERY

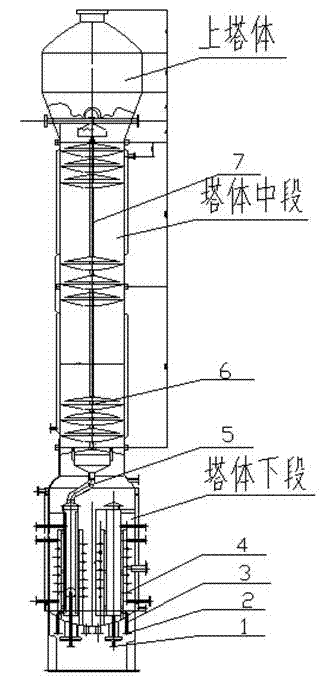

Adjustable stripping tower for soybean mixing oil precipitation

The invention relates to an adjustable stripping tower for mixing oil precipitation. According to the present invention, based on the condition that the current stripping tower can not adapt to the changed production output, the stripping tower disc are arranged into the adjustable device; and according to the design, the lower section of the tower body comprises a mammoth pump, a snake pipe, a separation plate and multiple sections of oil pipes, the middle section of the tower body comprises a center shaft, discs, a sleeve pipe and a center sleeve shaft, the multiple groups of the discs are sleeved by adopting the center shaft as the shaft, each group of the discs comprise the upper disc and the lower disc, and is separated through the sleeve pipe, the upper disc is fixed through the center sleeve shaft, the lower disc is fixed on the sleeve pipe through the tension rib, the diameters of the upper disc and the lower disc and the distance between the upper disc and the lower disc can be adjusted, and the distance between the upper disc and the lower disc can be adjusted according to the productivity.

Owner:九三食品股份有限公司

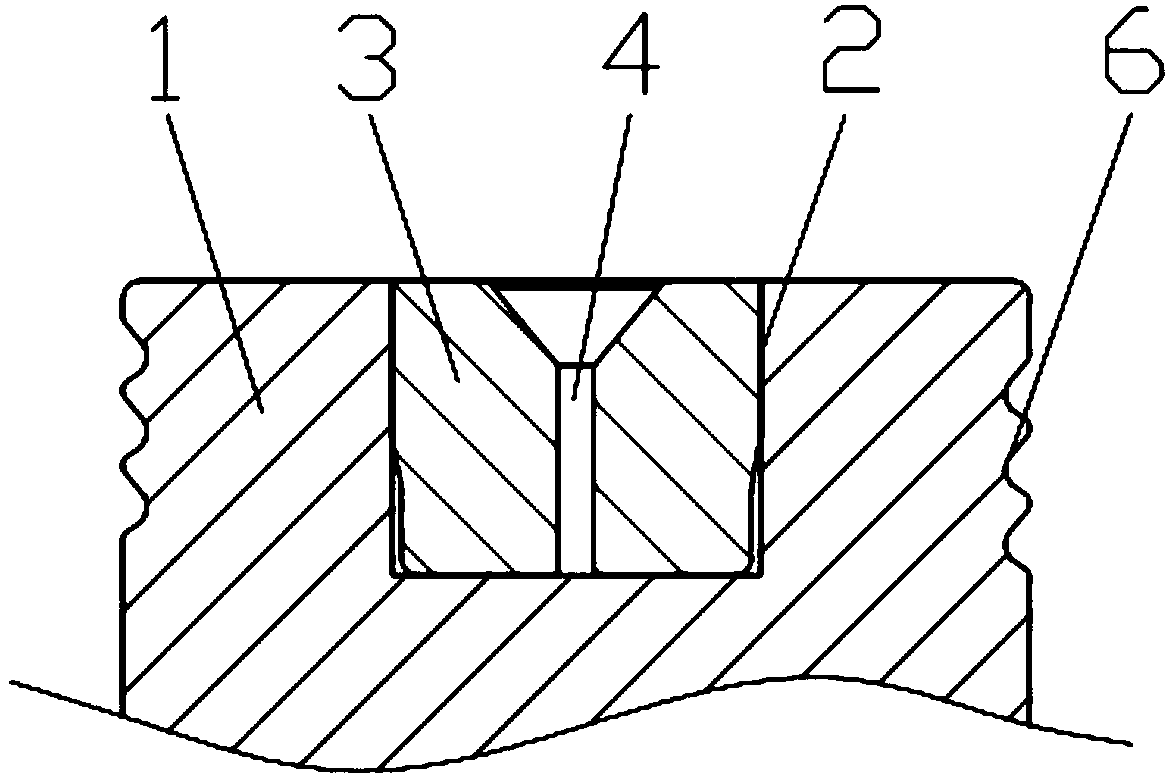

Fine blind hole processing process

The invention discloses a fine blind hole processing process which comprises the following steps: step 1: processing an insert hole at the position, where a fine blind hole needs to be processed, of aworkpiece, wherein the depth of the insert hole is equal to that of the fine blind hole, and the inner diameter of the insert hole is larger than that of the fine blind hole; step 2, processing an insert matched with the insert hole; step 3, processing a through hole on the insert by adopting a wire cutting method, wherein the size process of the through hole is the same as that of the fine blindhole; and step 4, fixedly mounting the insert in the insert hole. Through the above fine blind hole processing process, the size process of the fine blind hole can be guaranteed and processing residues can be prevented from remaining in the fine blind hole.

Owner:SUZHOU LIANKAI PRECISION MOLD

Automobile anti-pinch device sensitive to trigger, convenient to install and low in cost

PendingCN109339618ASimple structureEasy to installPower-operated mechanismAlarmsElectrical resistance and conductanceComputer module

The invention relates to an automobile anti-pinch device sensitive to trigger, convenient to install and low in cost. The device comprises an anti-pinch strip body, a fixed support, a sealing cover, aconnecting wire, a wire interface and an anti-pinch controller; the anti-pinch strip body is an insulating rubber body whose interior is hollow, a first conductor, a second conductor, a third conductor and a fourth conductor are arranged on the inner surface of the insulating rubber body, and a wire is arranged in each conductor; the four conductors are arranged on the inner surface of the insulating rubber body at equal intervals in the circumferential direction, and a gap is reserved between every two conductors; an assembling part is arranged at the lower part of the insulating rubber body; and a resistor is arranged at the end of the anti-pinch strip body, and the two ends of the resistor are electrically connected with the wires. The device has the advantages that the structure is simple, the sensitivity is high, the cost is low, the technical problem that an anti-pinch module is low in sensitivity and cannot detect the state of an obstacle is solved, so that the sensitivity reduction and even failure caused by abrasion or oxidation of conductor parts are avoided, and the use safety is improved.

Owner:SHANGHAI RONGNAN TECH CO LTD

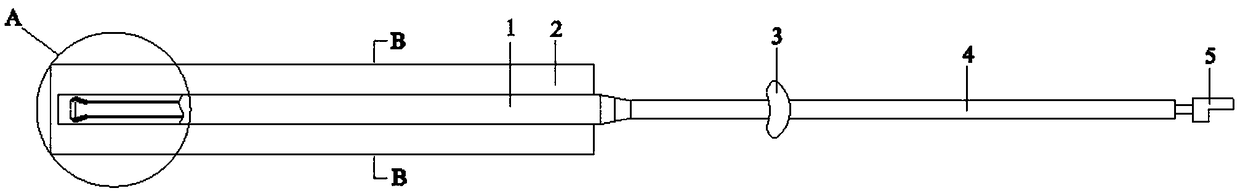

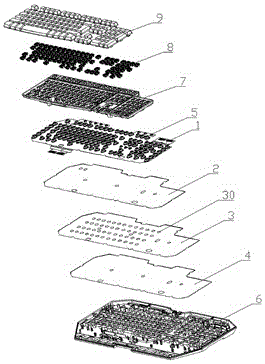

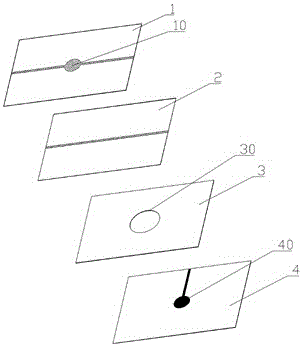

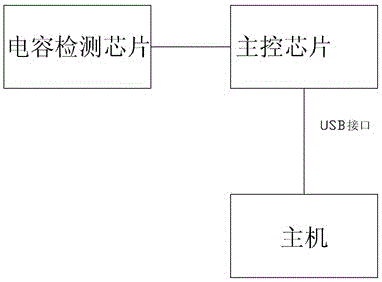

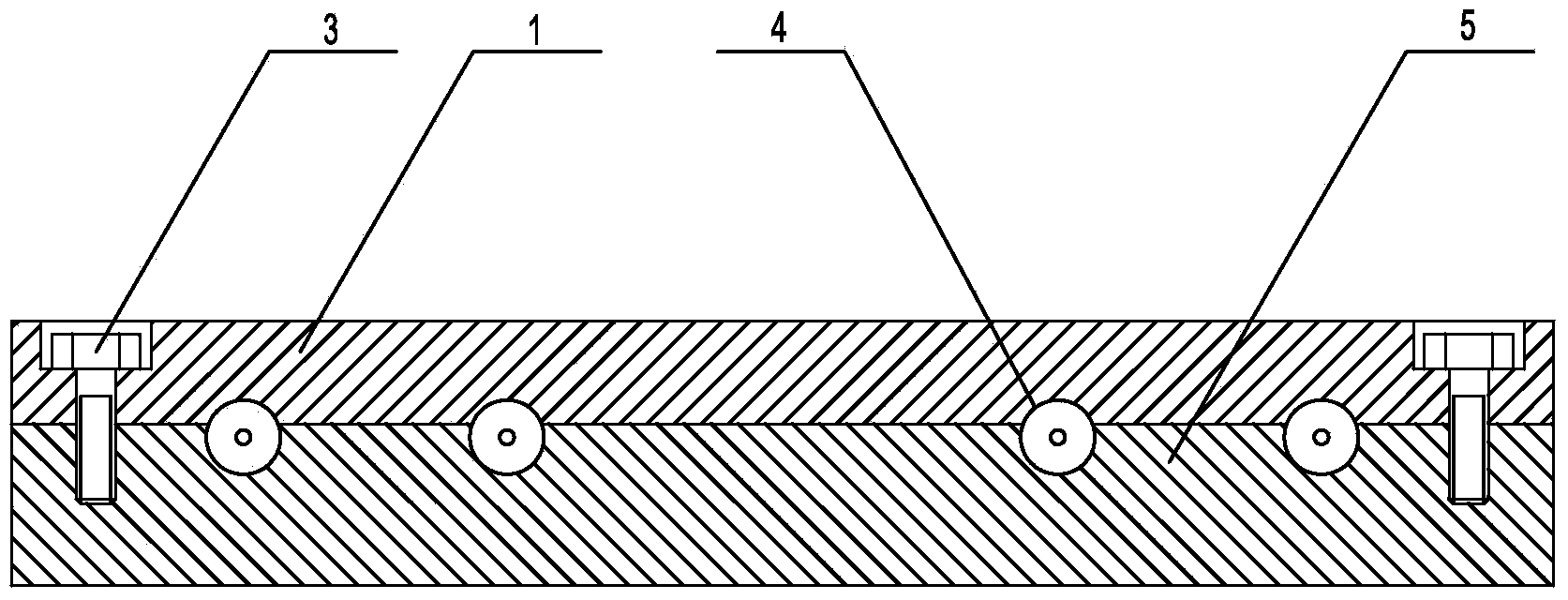

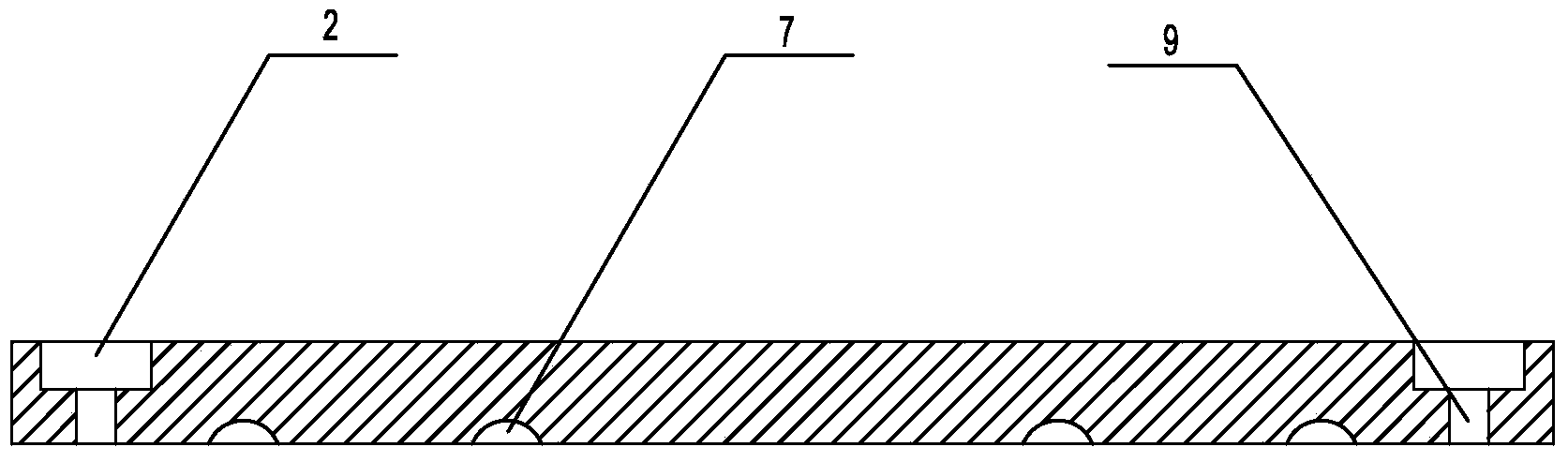

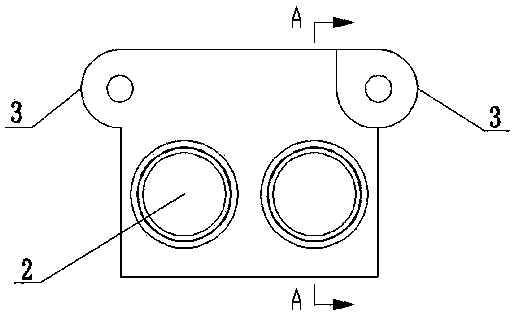

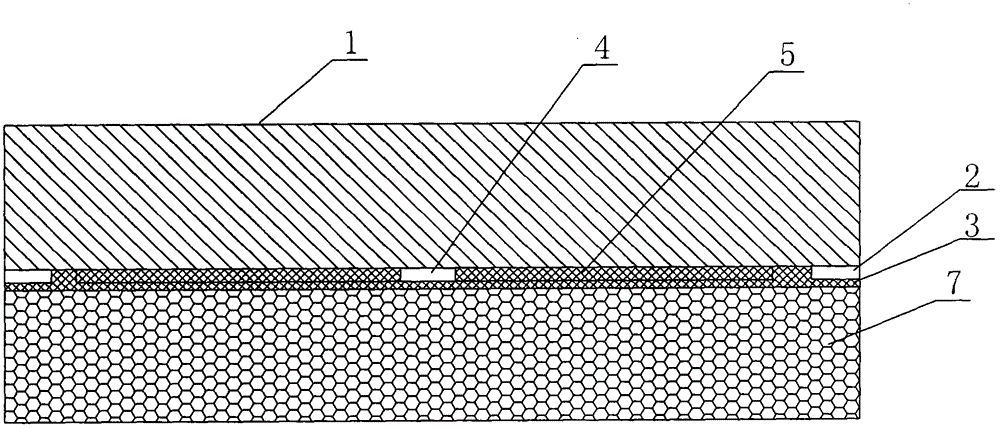

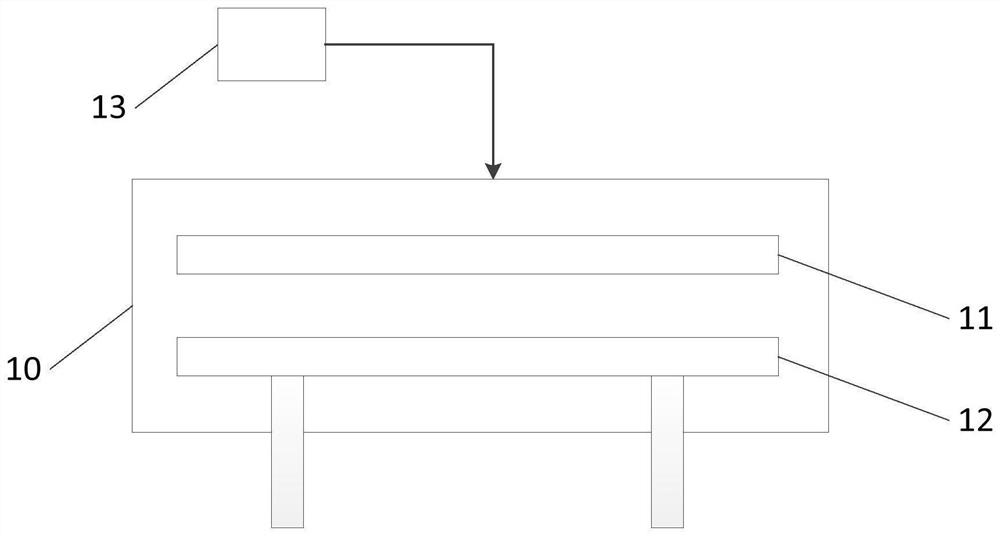

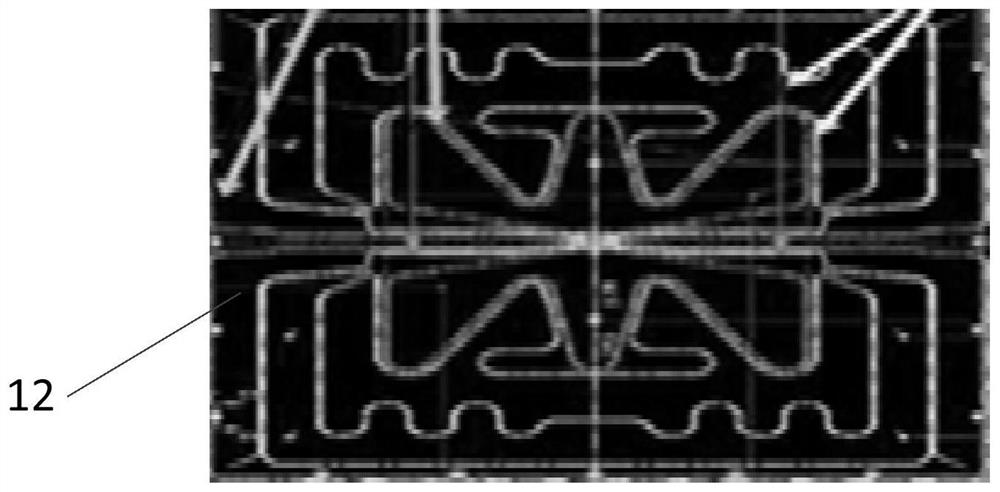

Electrostatic capacitive film touch keyboard

ActiveCN103744522BSimple processReduce manufacturing costInput/output for user-computer interactionElectricityCapacitance

The invention discloses a static-capacitive film touch keyboard which is simple in process, low in production cost, low in wear rate and good in contact stability. The static-capacitive film touch keyboard comprises a capacitive-type detection chip and a static-capacitive film circuit board, wherein the static-capacitive film circuit board comprises a first film circuit layer (1), a conductive insulation layer (2), a film spacer layer (3), and a second film circuit layer or a PCB layer (4) which are sequentially arranged; a first matrix circuit and a plurality of upper contacts (10) are arranged on the lower surface of the first film circuit layer (1), a second matrix circuit and a plurality of lower contacts (40) are arranged on the upper surface of the second film circuit layer or the PCB layer (4), through holes (30) ensuring the formation for capacitor units, of the plurality of upper contacts (10), the plurality of lower contacts (40) and the film spacer layer (3) are formed in the film spacer layer (3); both of the first matrix circuit and the second matrix circuit are connected with the capacitive-type detection chip.

Owner:G TECH TECH

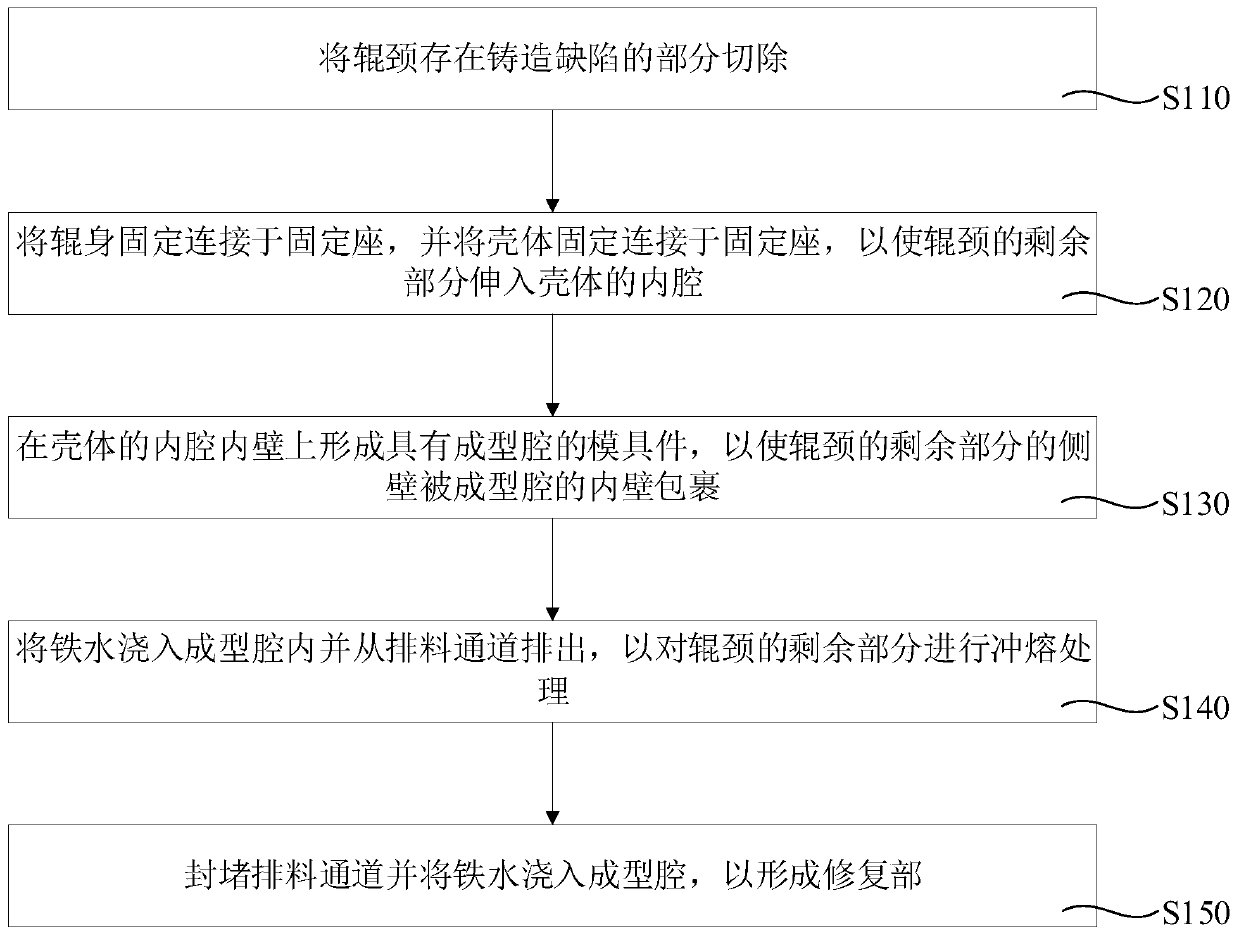

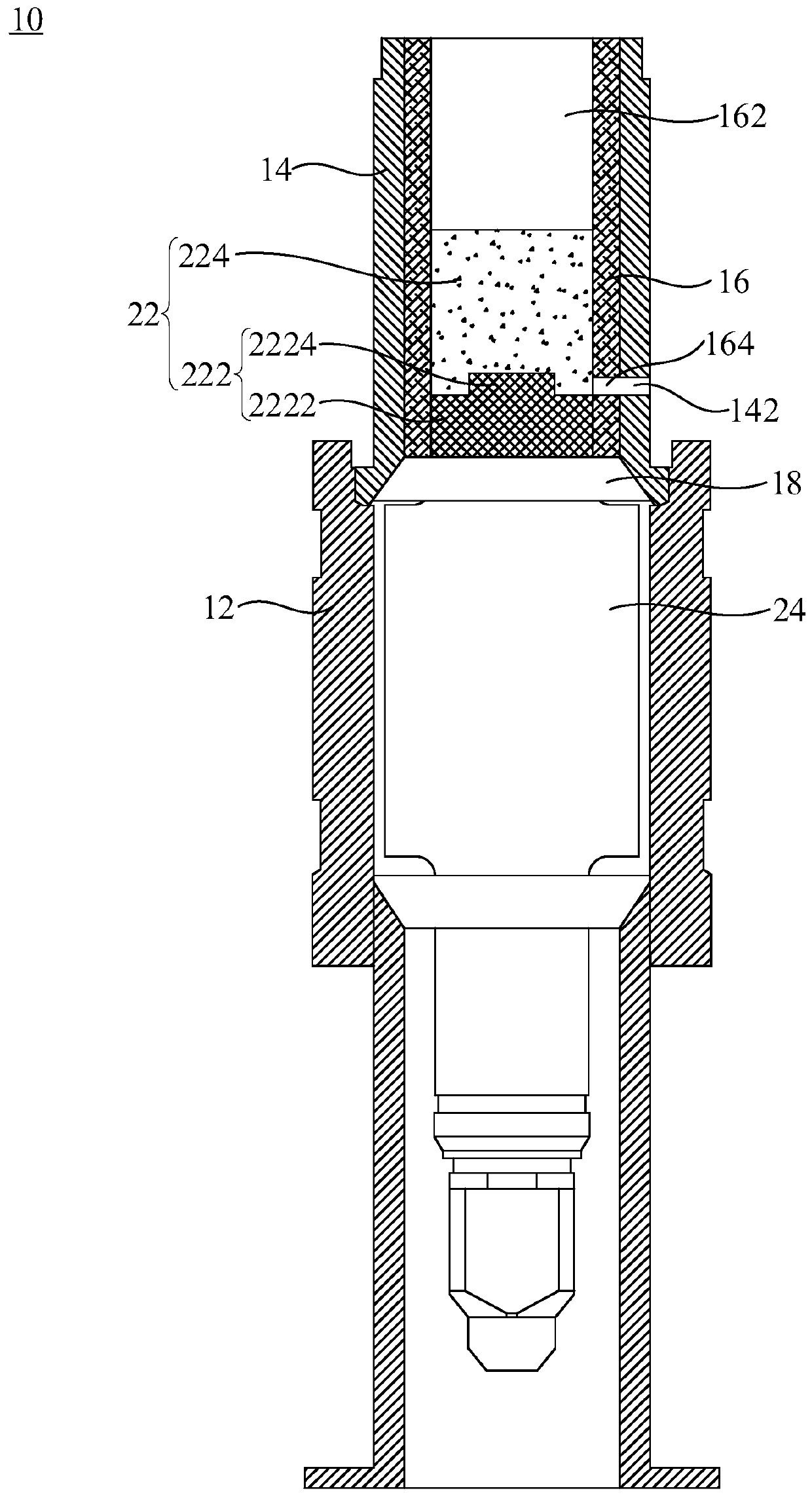

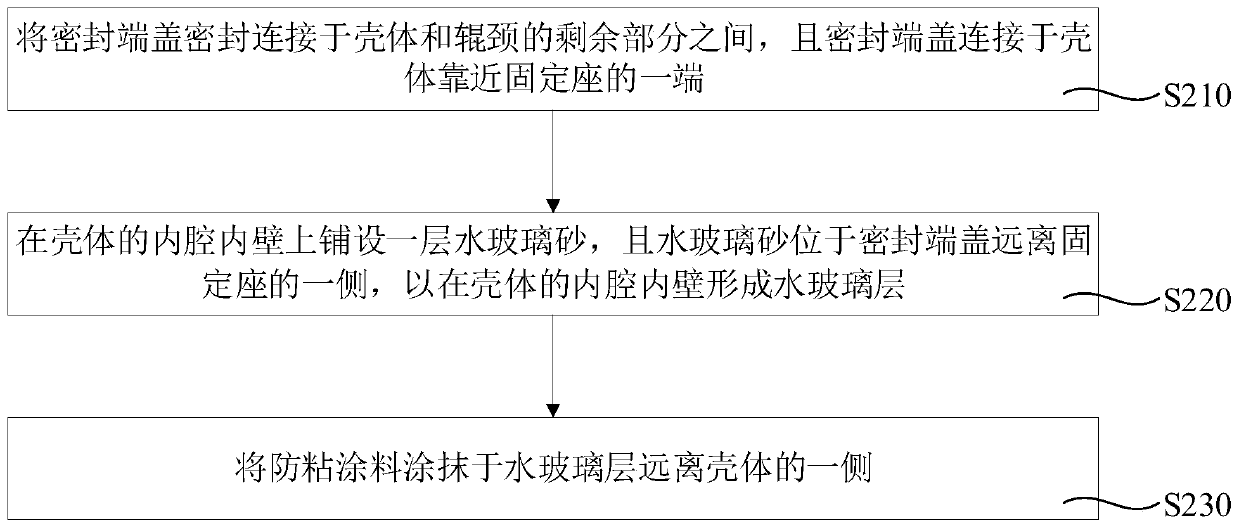

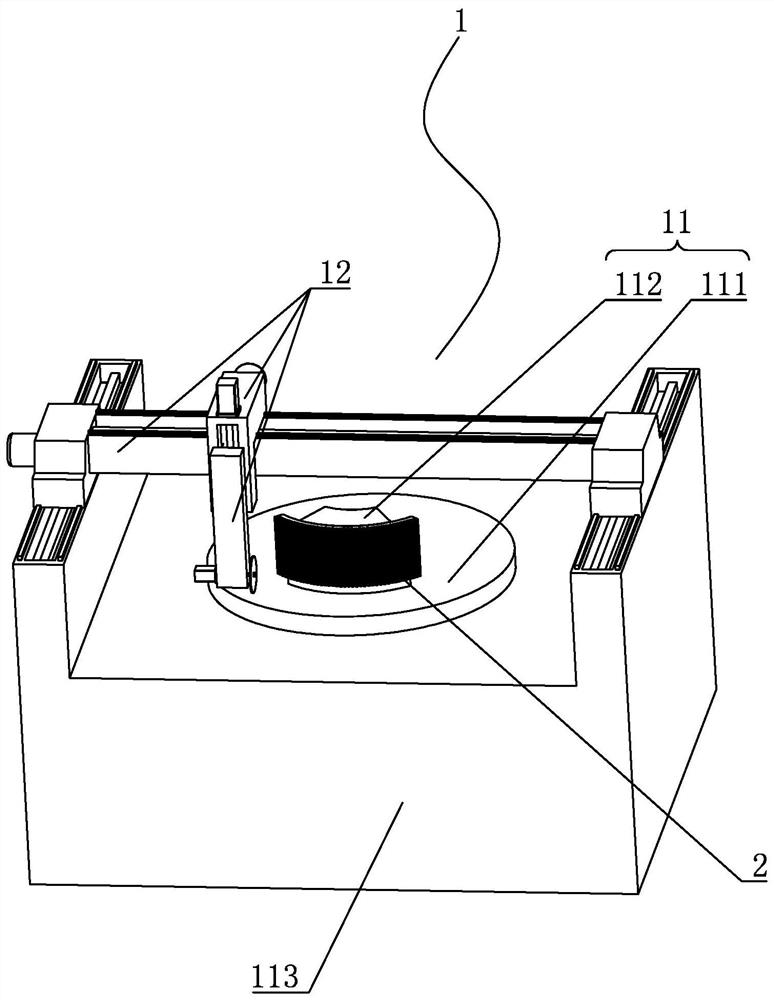

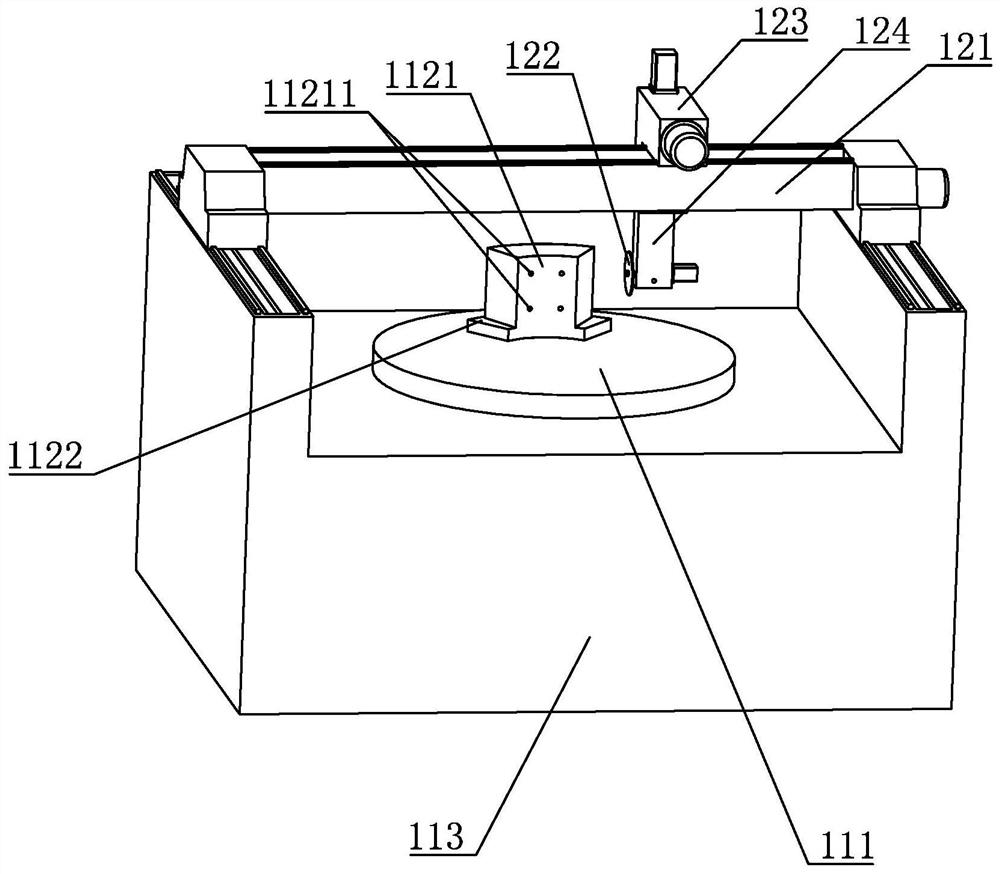

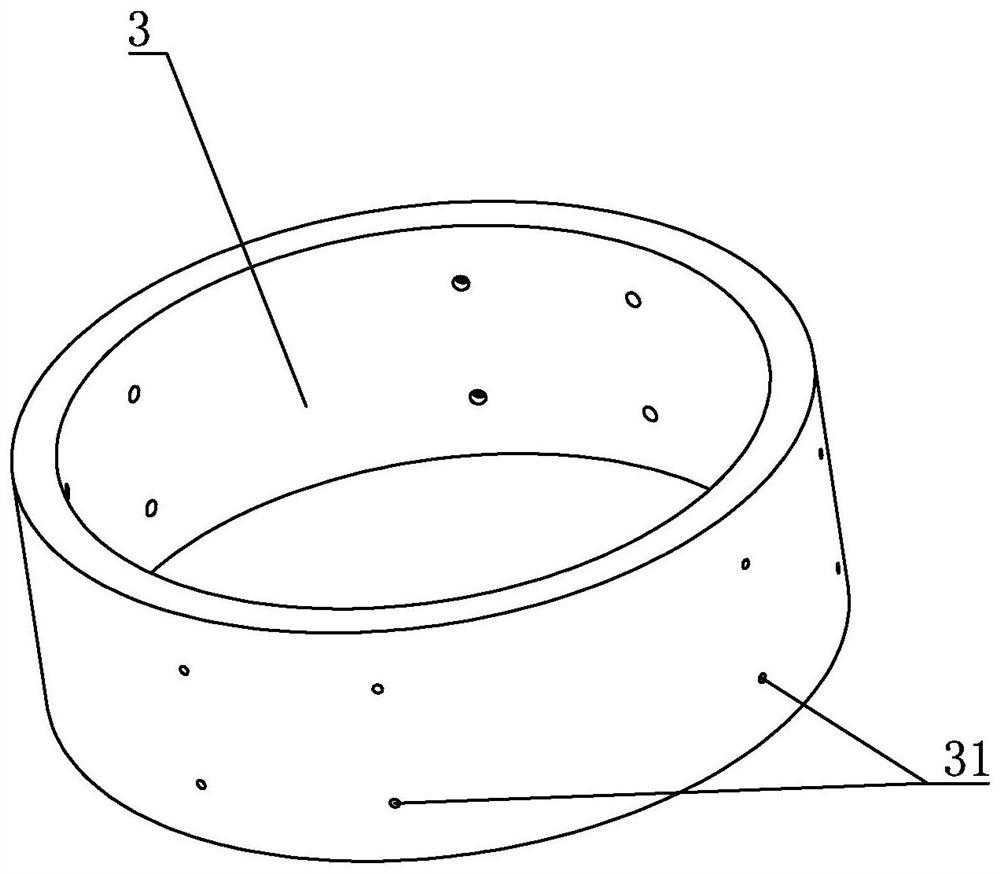

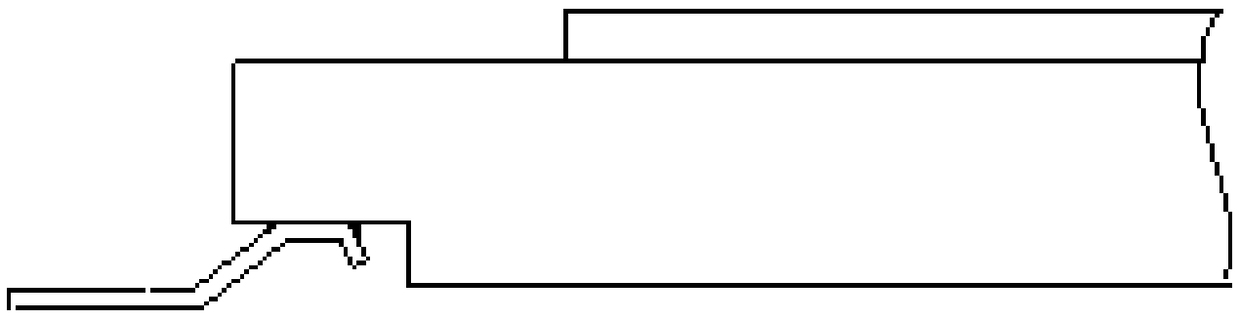

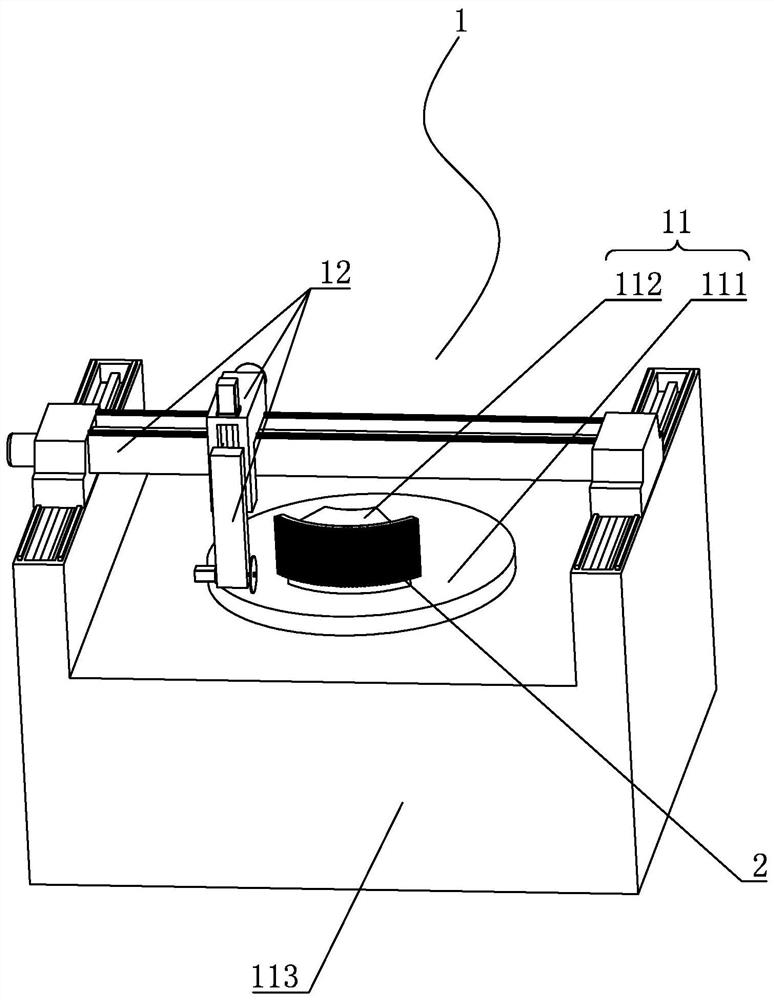

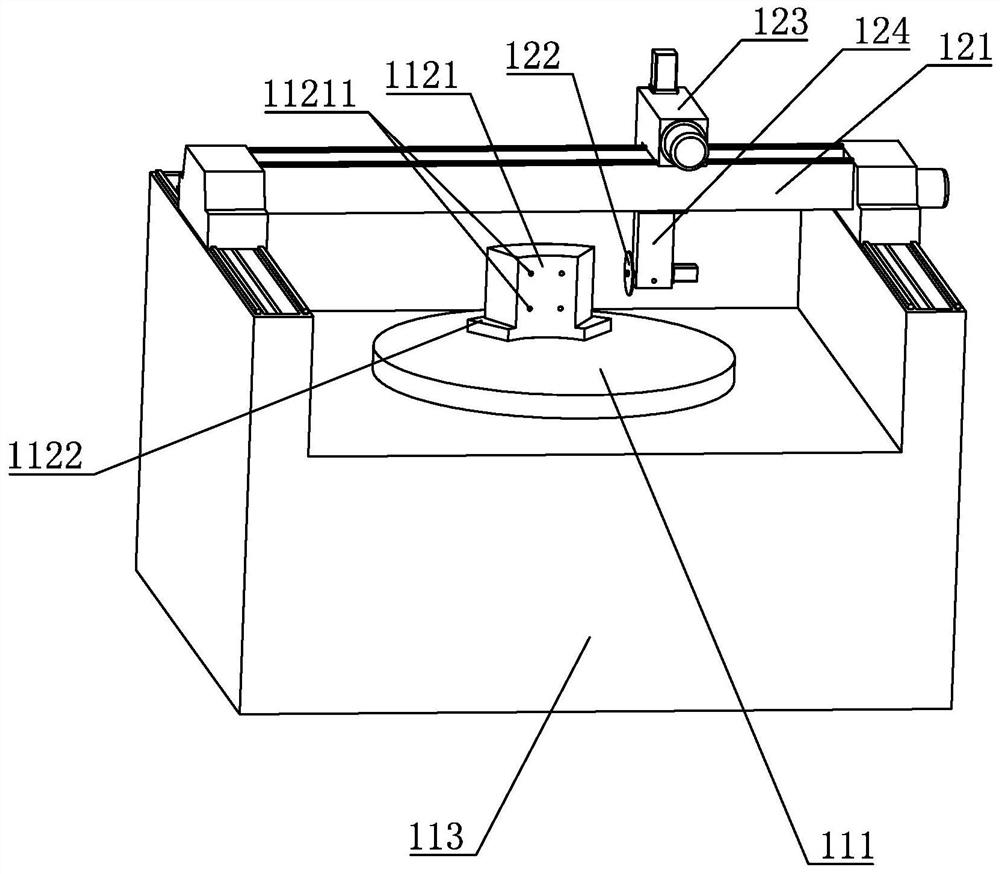

Repair method for roller and repair equipment for roller

InactiveCN110216270AReduced Repair MethodReduce manufacturing costRolling equipment maintainenceMetal rolling arrangementsRestoration deviceEngineering

The invention relates to a repair method for a roller. The roller comprises a roller neck, a roller body and a shaft head which are sequentially and fixedly connected. For a roller with casting defects in the roller neck portion, after the defect portion is cut, the roller is fixed to a fixing base. A shell is fixedly connected to the fixing base, and the rest of the roller neck extends into an inner cavity of the shell. Then a mold part is formed on the inner wall of the inner cavity of the shell. After arrangement, molten iron is poured into a molding cavity firstly, and molten iron poured in firstly is used for conducting flush-melting treatment on the rest of the roller neck. Molten iron for conducting flush-melting treatment on the rest of the roller neck is discharged from a discharging channel. Then the discharging channel is plugged up; besides, molten iron is poured into the molding cavity again; and at the moment, the discharging channel has been plugged up, molten iron poured in for the second time is stacked in the molding cavity, and after molten iron is cooled and solidifies, a repaired portion fixedly connected with the rest of the roller neck can be formed. By meansof the repair method for the roller, repair of rollers with defects can be achieved; and the manufacturing cost is effectively lowered. The invention further relates to repair equipment for the roller.

Owner:HUNAN XIANGNENG SPECIAL STEEL

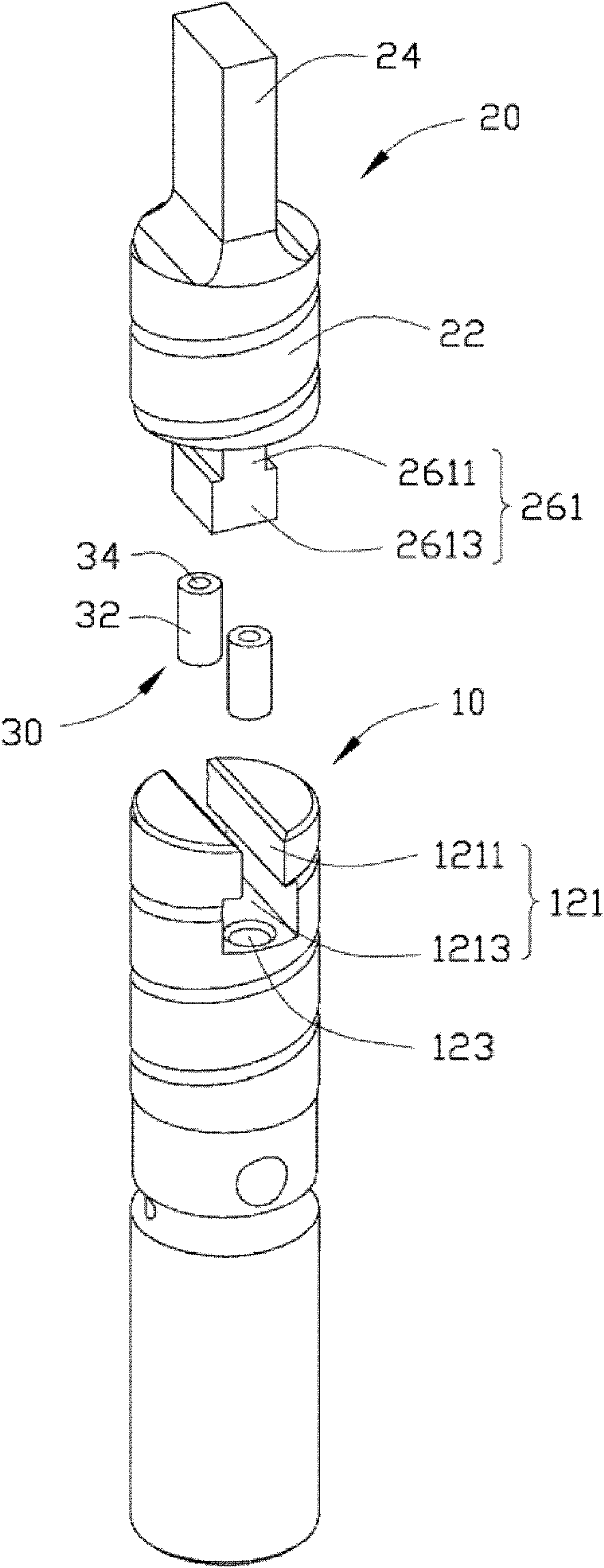

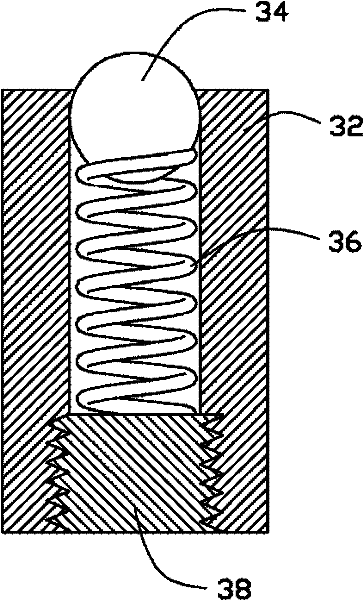

Invisible screw device and fastening method

ActiveCN103495958AAvoid disassemblyImprove securityClosed casingsDigital data processing detailsEngineeringElectronics

The invention discloses an invisible screw device and a fastening method and belongs to the field of consumer electronics. The device is arranged in a machine shell and used for being fixedly connected with the machine shell. The device comprises a driving portion, a screw, a nut and a chip. The driving portion is fixedly connected in a shell body of the machine shell and connected with the screw, the nut is fixedly connected in the other shell body of the machine shell and matched with the screw, and the chip controls the driving portion to act. The driving portion drives the screw to move relative to the nut, and therefore meshing or disengaging of the screw and the nut is achieved. The invisible screw structure is adopted by the device and in the method, locking and attaching of an internal link can be achieved, and any structure cannot be seen from the appearance. Meanwhile, repeated detaching can be achieved without replacing and scraping any part, by starting the driving portion through the chip, non-professionals can be prevented from detaching a machine, and safety is increased.

Owner:XIAOMI INC

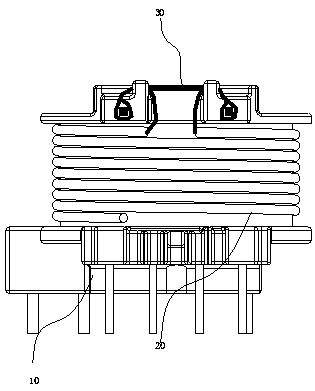

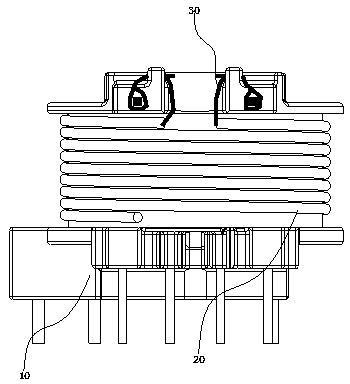

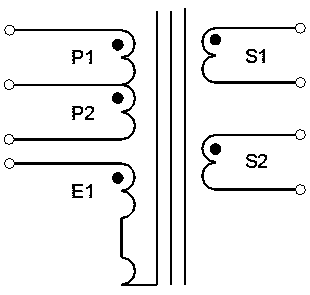

Adjustable common-mode transformer and common-mode adjusting method thereof

ActiveCN111312496ANo need to scrapReduce manufacturing costTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerControl theory

The invention discloses an adjustable common-mode transformer which comprises a framework, a magnetic core, at least one primary winding, at least one shielding layer winding and at least one secondary winding. The magnetic core is installed on the framework. The primary winding, the shielding layer winding and the secondary winding are wound on the framework layer by layer according to design requirements; the shielding layer winding comprises at least two sections of coils; and the adjacent coils are connected through taps. According to the adjustable common-mode transformer and the common-mode adjusting method thereof, by cutting the taps between winding coils of the shielding layer, the area and the shielding position of the shielding layer winding are adjusted by adjusting the common-mode value of the transformer such that the common-mode value of the transformer with the common-mode value deviating to a negative value or a positive value reaches a specified range, all transformers with poor common-mode values do not need to be scrapped, the production cost is saved, and the working efficiency is improved.

Owner:惠州三盛源电子有限公司

High-precision circular knitting machine part production process

ActiveCN112404576ANo need to scrapHigh processing error toleranceMetal sawing devicesMachine partsEngineering

The invention discloses a high-precision circular knitting machine part production process. The production process comprises the following steps that an inner needle cylinder blank and a plurality ofouter needle cylinder blanks which can be fixed and are fully distributed on the outer side wall of the inner needle cylinder blank are machined; threaded holes are machined in the inner side walls ofthe outer needle cylinder blanks, and connecting holes corresponding to the threaded holes are machined in the inner needle cylinder blank; the outer needle cylinder blanks are fixed; the outer sidewalls of the outer needle cylinder blanks are machined until the outer side walls of the outer needle cylinder blanks are full of needle grooves; and the plurality of machined outer needle cylinder blanks are fixedly connected to the inner needle cylinder blank together to form a needle cylinder. Through the process, the needle cylinder is machined, when the needle grooves in the outer surface ofthe needle cylinder are damaged in the working process, the outer needle cylinder blanks can be replaced according to the damaged positions, the whole needle cylinder does not need to be abandoned, and environmental protection and reliability are better achieved; and during machining, the situation that the whole needle cylinder fails to be machined and is abandoned due to the fact that errors occur in machining of a certain needle groove is avoided, and the machining error-tolerant rate is high.

Owner:漳州市永良针纺机械有限公司

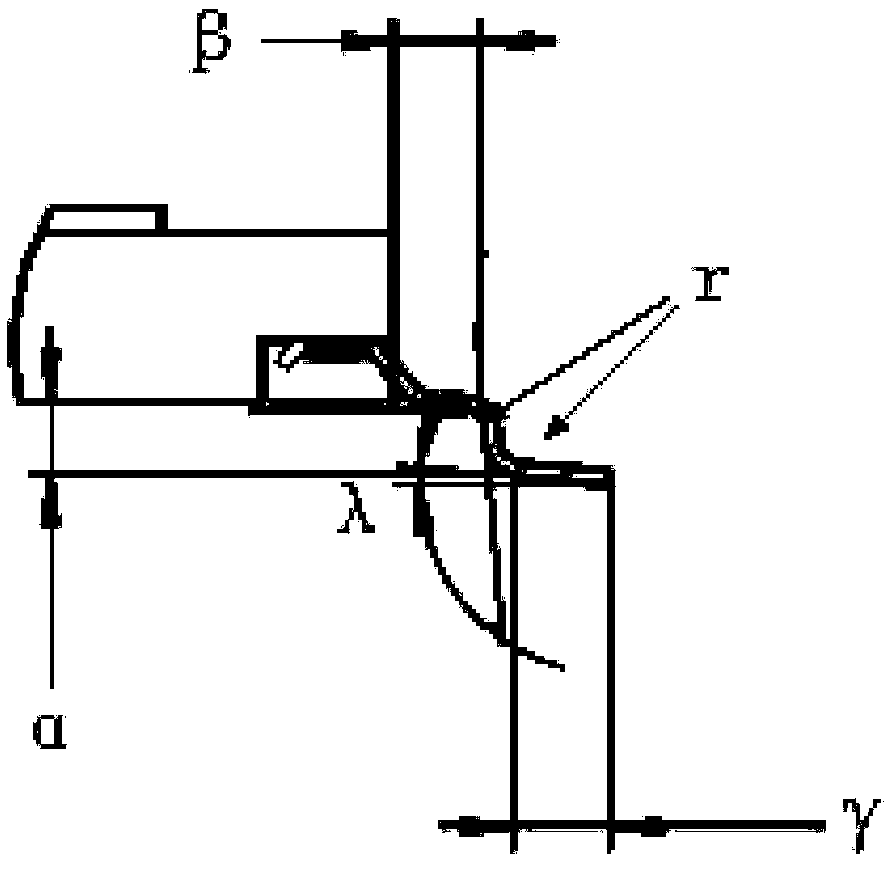

Wing-shaped lead SOP (small outline package) device and technological method for forming leads of wing-shaped lead SOP device

InactiveCN109360817AReduce failure rateImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesFailure rateShear stress

The invention discloses a wing-shaped lead SOP (small outline package) device and a technological method for forming leads of the wing-shaped lead SOP device. An end of each lead is fixed to a pin ofthe wing-shaped lead SOP device, and the leads are sequentially divided into oblique downward sections, horizontal sections, vertical sections and oblique sections from fixed ends to free ends; the oblique downward sections and the horizontal sections extend towards the outer sides of the wing-shaped lead SOP device and are in bending transition with one another, the vertical sections are in circular arc transition with the horizontal sections and the oblique sections, the oblique sections are horizontally downwardly oblique, and the leads are symmetrically arranged at two ends of the wing-shaped lead SOP device. The wing-shaped lead SOP device and the technological method have the advantages that stress relief spaces for the leads of the wing-shaped lead SOP device can be enlarged and canbe obviously increased, accordingly, the failure rate of the wing-shaped lead SOP device under long-term shear stress and high-temperature creep effects can be effectively lowered, and the post-weldreliability of the wing-shaped lead SOP device further can be improved.

Owner:XIAN MICROELECTRONICS TECH INST

Detachable heating disk

InactiveCN104302025ASimple processing technologyEasy to assembleHeater elementsFurnace heating elementsEngineeringMachining process

The invention discloses a detachable heating disk which comprises a heating disk body. The heating disk body comprises a base and an upper cover arranged on the base; a downwards-concave lower pipe groove is formed in the upper surface of the base; a heating pipe is arranged in the lower pipe groove; an upwards-concave upper pipe groove, corresponding to the heating pipe, is formed in the lower surface of the upper cover; the upper cover is connected with the base through a bolt in a matching manner. The heating disk disclosed by the invention has the characteristics that the machining process is simple, assembly is convenient, thermal efficiency is high and the heating disk can be disassembled for maintenance, the heating pipe is separately replaced, and resources are saved. The heating disk disclosed by the invention has a flat structure and can be widely applied to electric heating stoves.

Owner:浦北县白石水锅厂

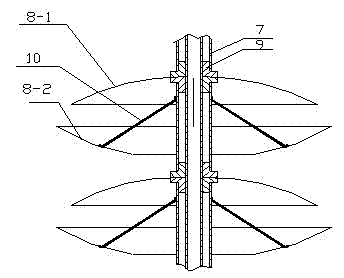

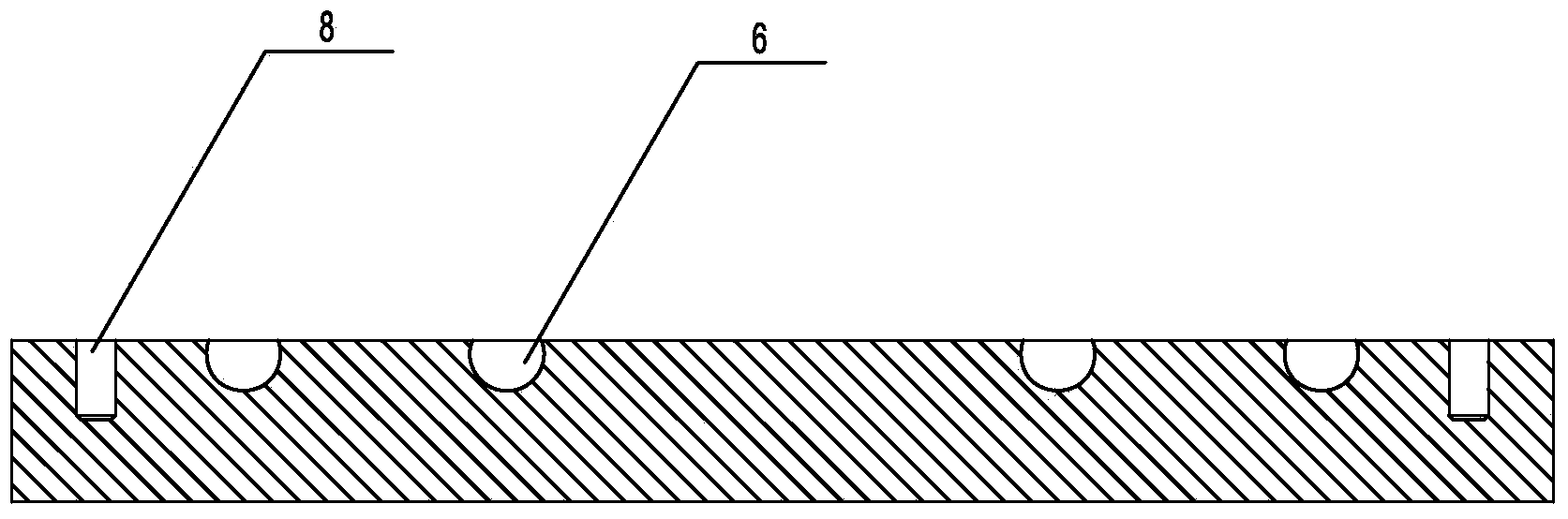

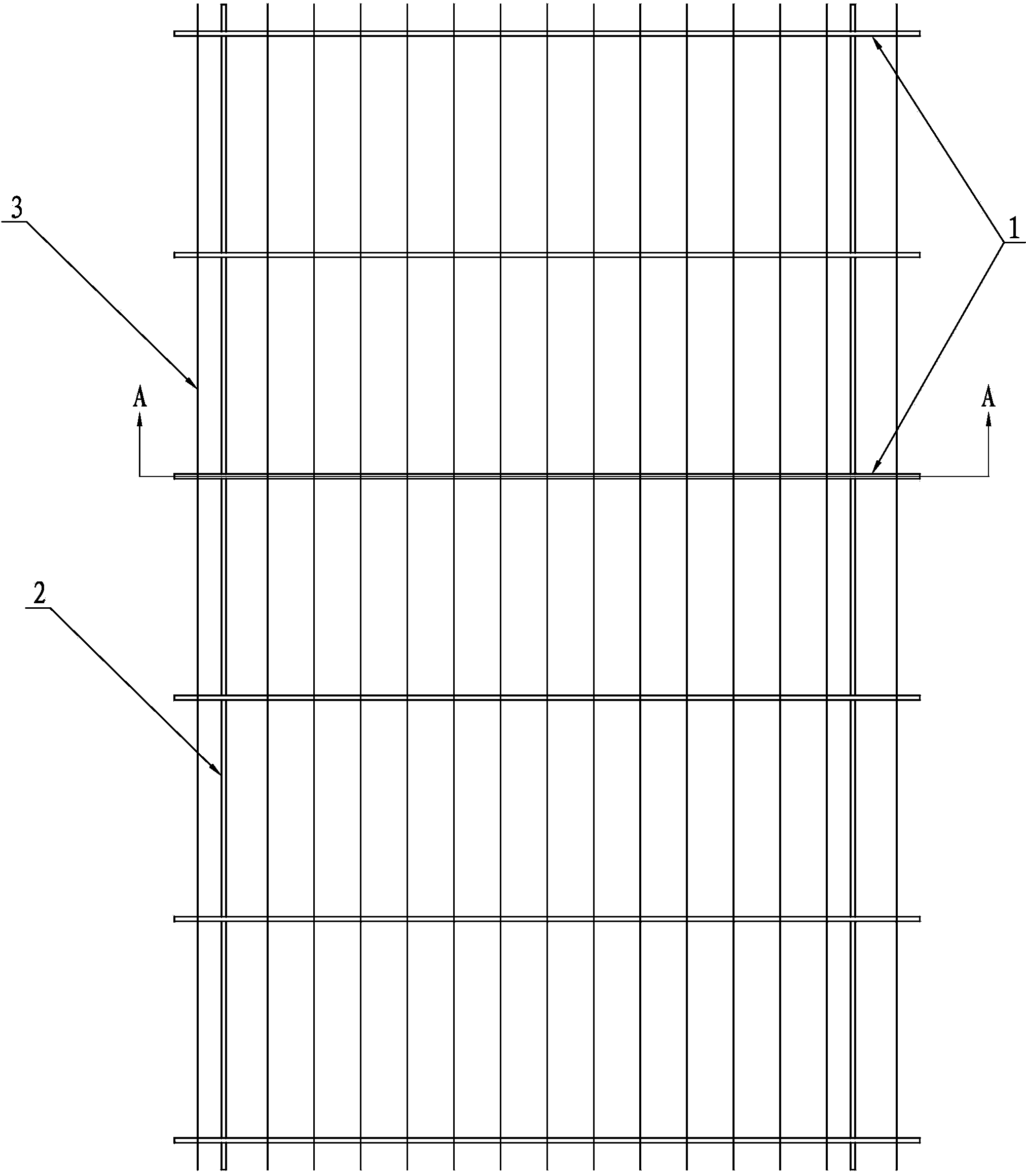

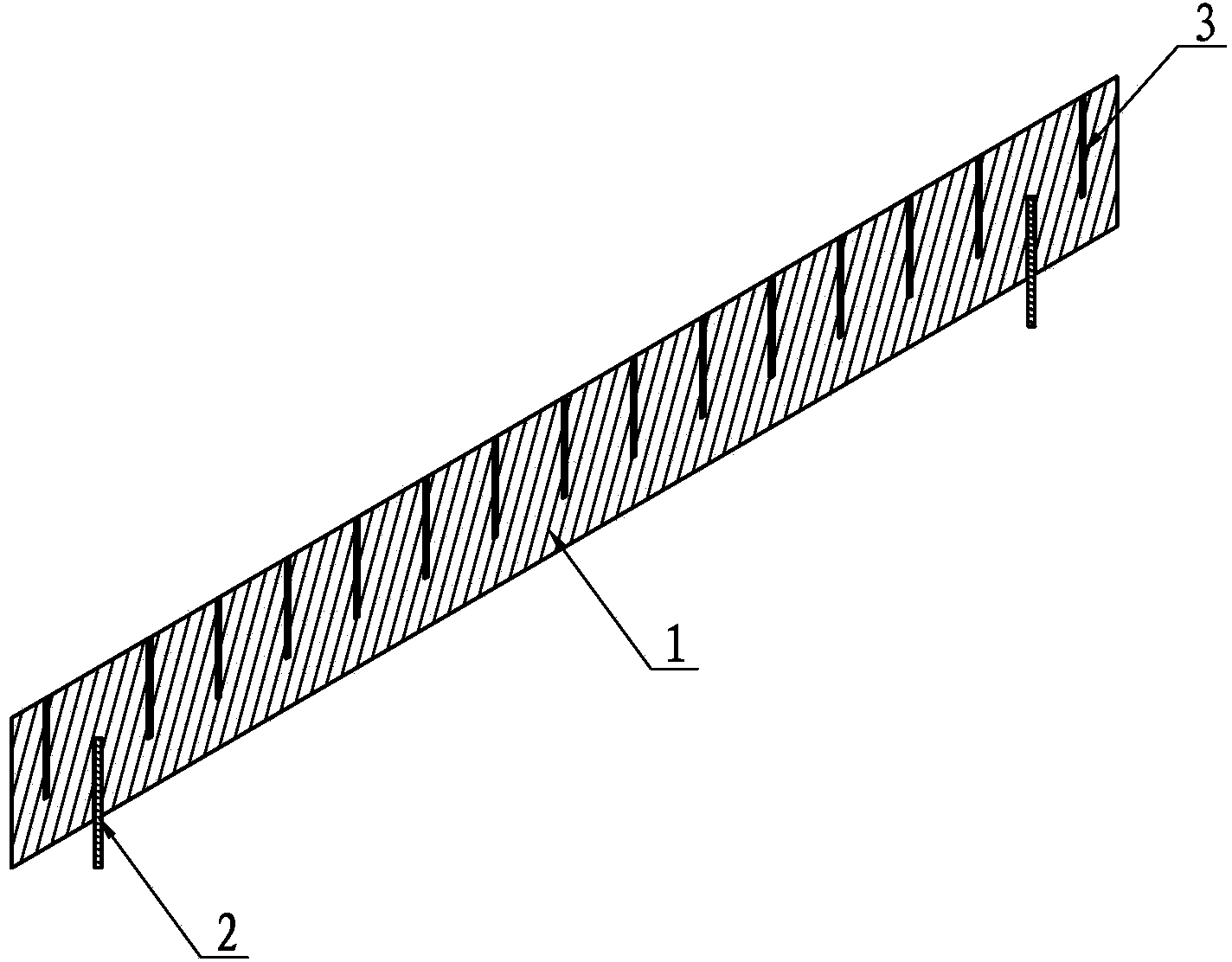

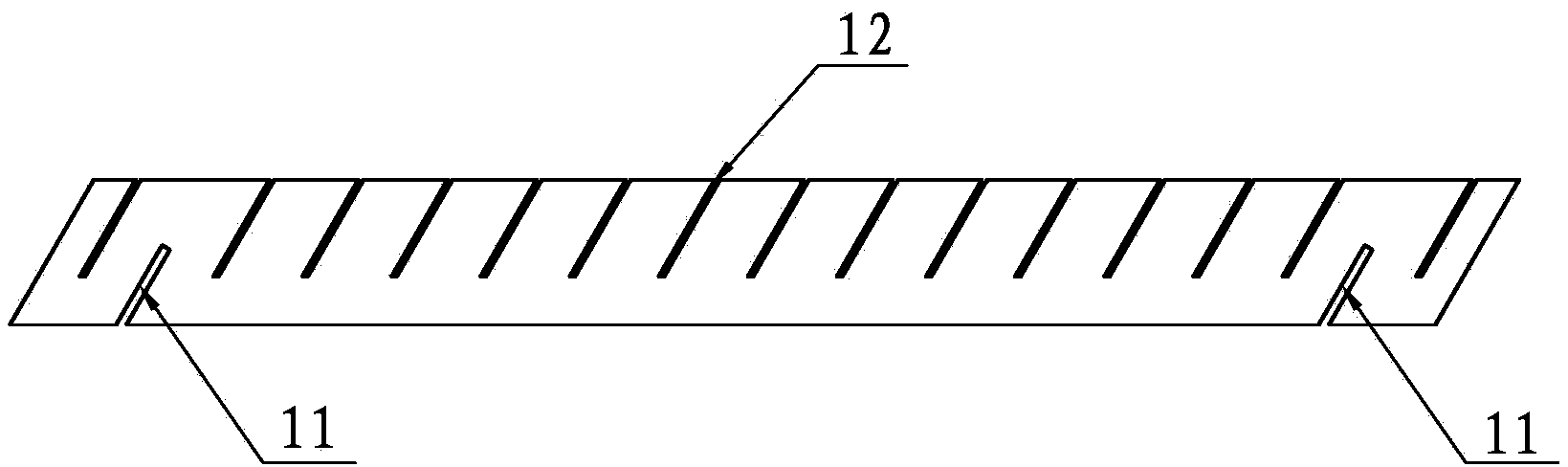

Insertion sheet spliced type splash-proof grating of high-order water-saving cooling tower

InactiveCN103954167AEasy to pack and transportReduce manufacturing difficultyTrickle coolersWater savingCooling tower

The invention discloses an insertion sheet spliced type splash-proof grating of a high-order water-saving cooling tower. The insertion sheet spliced type splash-proof grating comprises transverse fixed plates, longitudinal fixed plates and longitudinal insertion sheets, wherein insertion slots with downward openings are formed in the transverse fixed plates; insertion sheet slots with upward openings are formed in the transverse fixed plates; a distance between every two adjacent insertion sheet slots is 3-60 mm; meshing slots with upward openings are formed in the longitudinal fixed plates; a distance between every two adjacent meshing slots is 50-500 mm; all the longitudinal fixed plates are arranged in parallel, so that the transverse fixed plates and the longitudinal fixed plates are perpendicularly meshed to form a right-angle ladder-shaped framework; the longitudinal insertion sheets are inserted into the corresponding insertion sheet slots in the transverse fixed plates. In an actual production process, all the parts are respectively molded in a pressing manner, so that the mold manufacturing difficulty and the part pressing difficulty are reduced, large-scale tissue production is facilitated, the manufacturing cost is greatly lowered, classification package, transportation and on-site assembling are facilitated; the transportation cost is lowered, replacement and maintenance are convenient to realize, and the cost is lowered.

Owner:常州金坛塑料厂

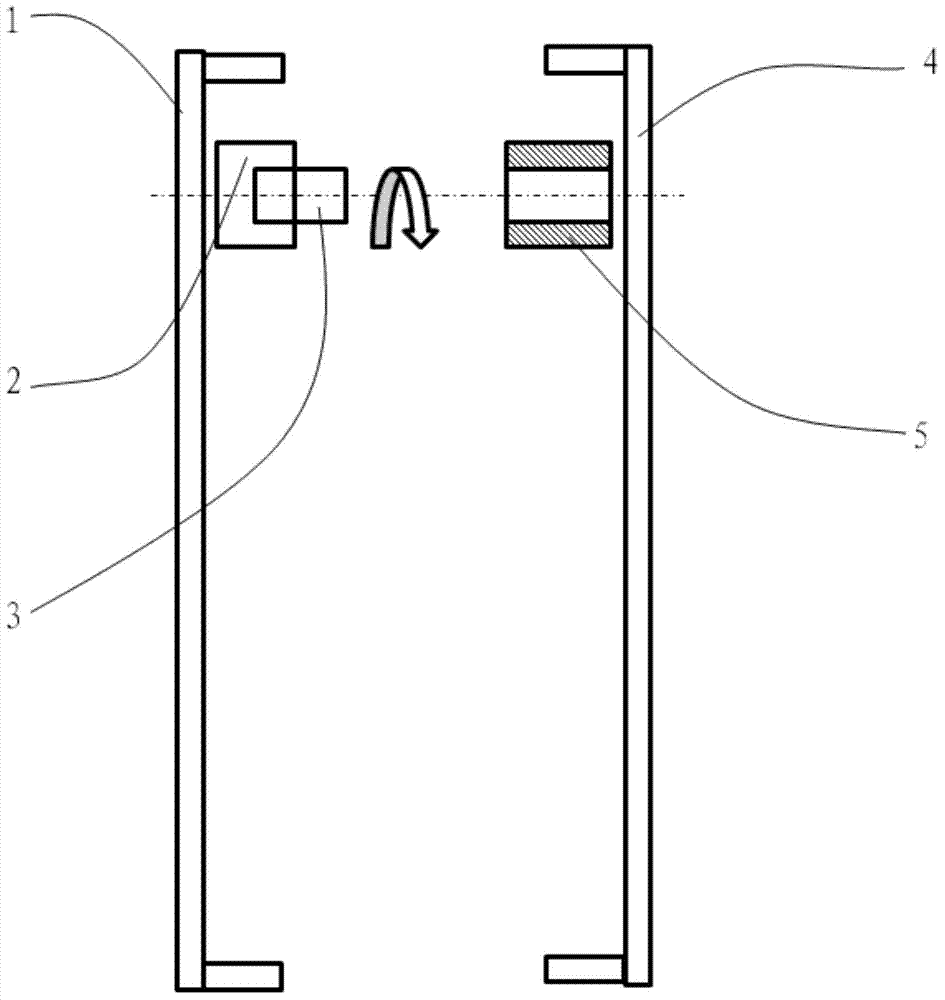

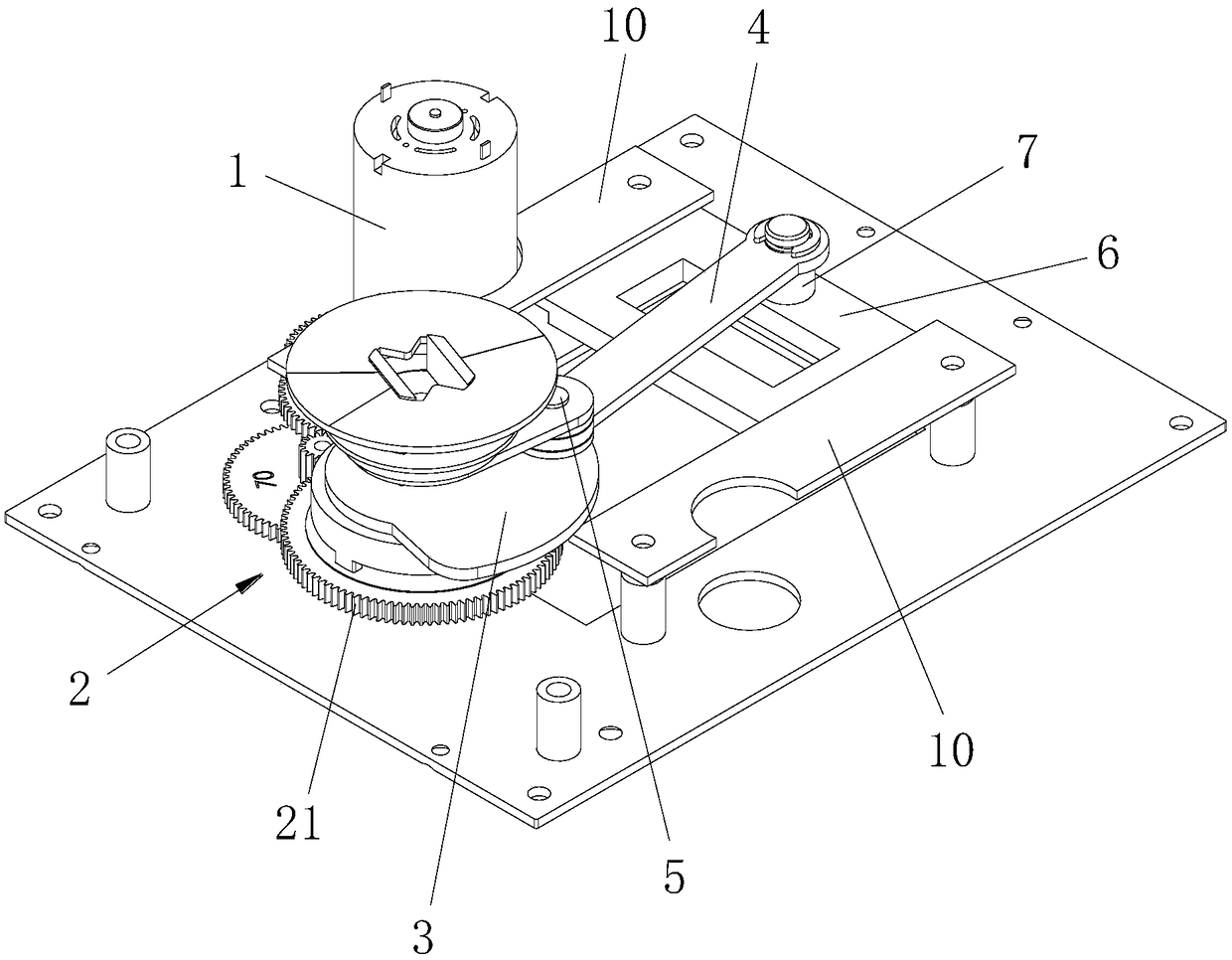

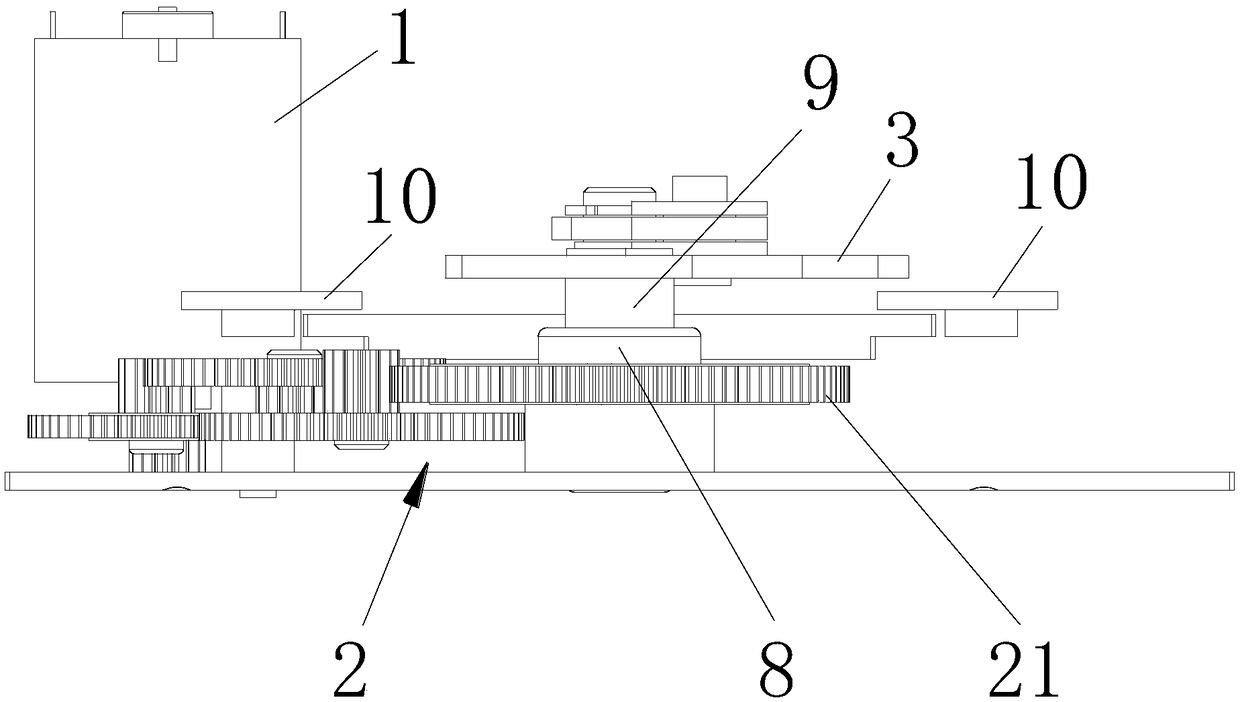

Electric operating mechanism

PendingCN109494131ALower the altitudeLow costProtective switch operating/release mechanismsMotor driveReciprocating motion

The invention discloses an electric operating mechanism comprising a sliding block that is capable of driving a circuit breaker directly or indirectly to realize opening or closing based on own reciprocating motion. The electric operating mechanism also includes a cam, a connecting rod, one pair of guiding pressing plates, and a motor. One end of the connecting rod is in rotation connection with the cam and the other end rotates with the sliding block. The guiding pressing plates are arranged at the two opposite sides of the sliding block and enable the sliding block to slide back and forth. The motor drives the cam to make rotation by a gear set; the e output shaft of the motor is disposed downwardly. The cam is arranged right above the gear set; and the sliding block and the gear set arearranged in a horizontal direction. Compared with the prior art, the electric operating mechanism has the following advantages: the height of the electric operating mechanism is reduced effectively;the moving direction of the sliding block is controlled by the guiding pressing plates, so that the overall height of the mechanism is reduced and the cost is lowered; and since connecting structuresof all parts are dismounted conveniently, the parts can be replaced separately if any damage is caused and thus overall scrapping is not needed, so that the cost is lowered.

Owner:SUZHOU JINGTAI ELECTRIC

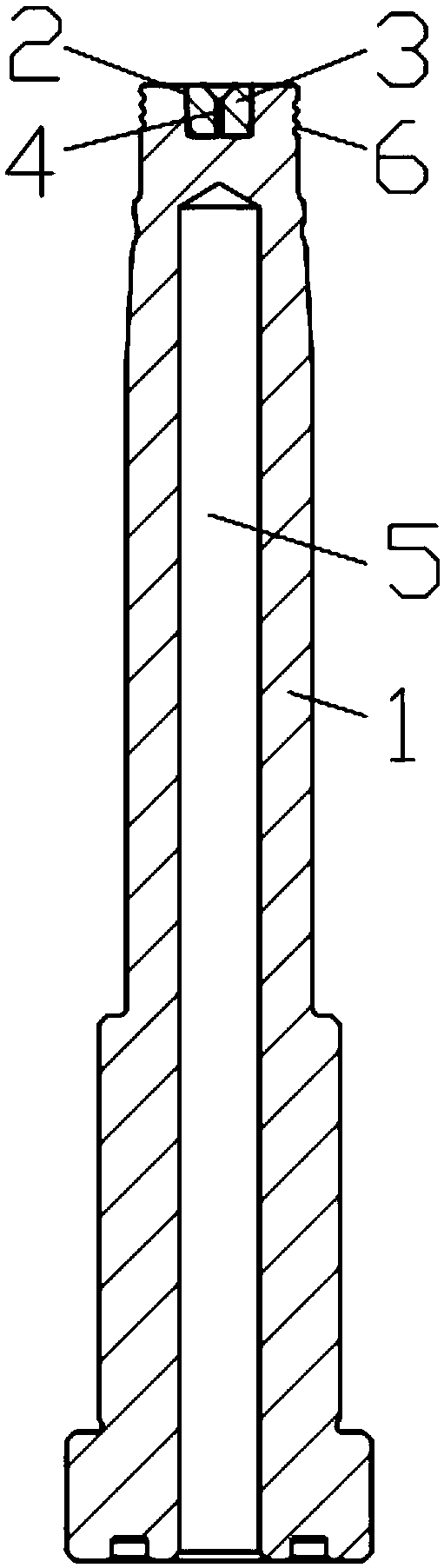

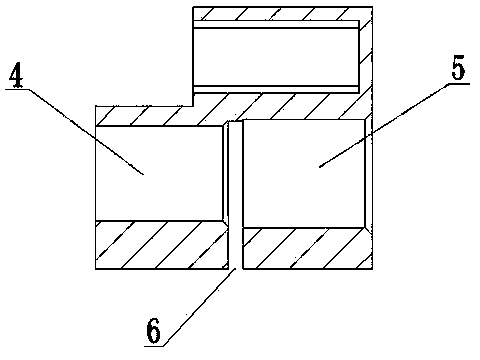

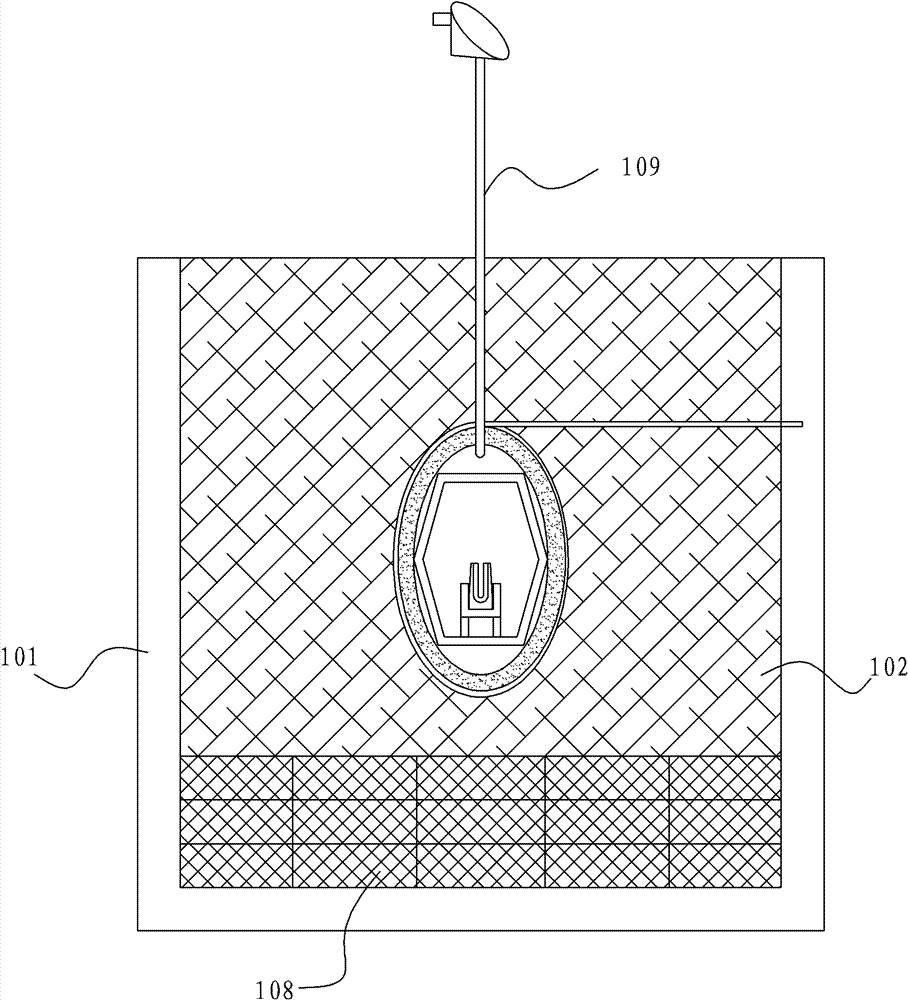

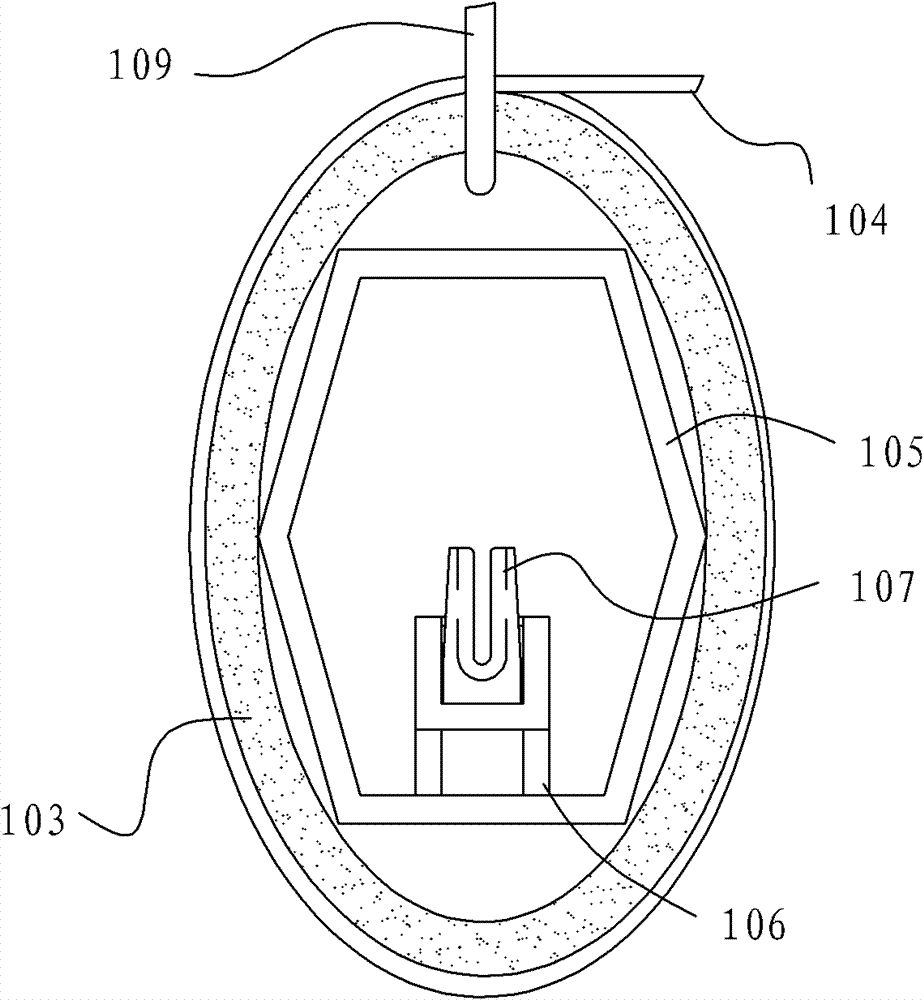

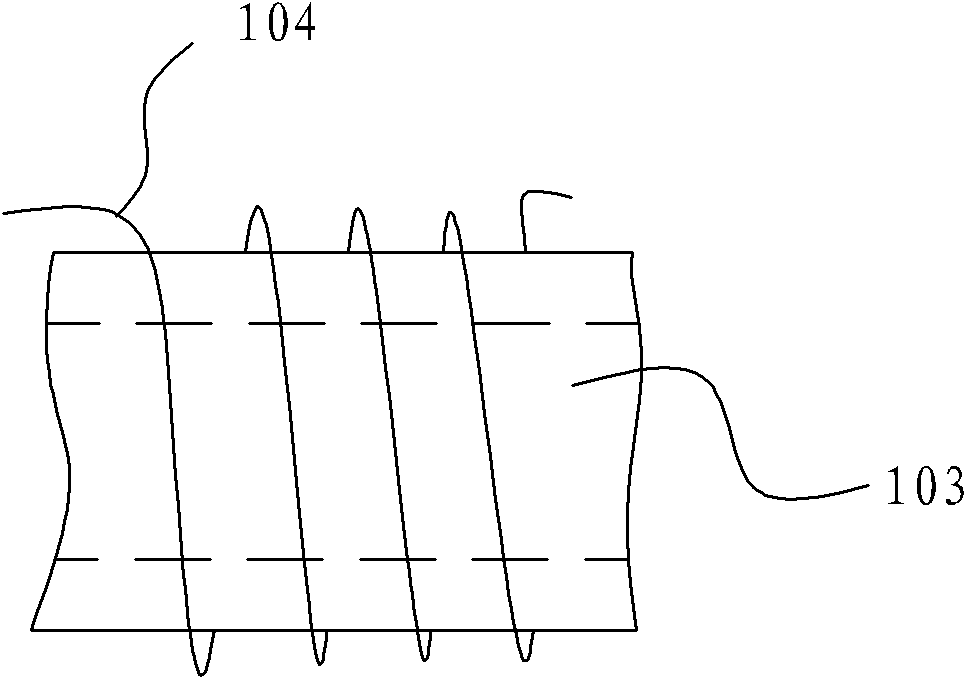

An adjustable punching module applied to a mold

The invention discloses an adjustable punching die block applied to a die. The die block comprises a base plate of the die, a rectangular step hole is formed in the base plate, a rectangular embeddingdie block is inserted in the step hole of the base plate, a punching hole is formed in the center of the embedding die block, arc channels are formed in the four corners of the step hole of the baseplate, a rectangular concave table is formed on the side wall of the embedding die block, a clamping groove is formed in the bottom face of the concave table, a permanent magnet block is fixedly inserted in a clamping groove of the embedding die block, an adjusting gasket is inserted in the concave table of the embedding die block, the end faces of the two sides of the adjusting gasket abut against the inner wall of the step hole of the base plate of the embedding die block and the bottom face of the concave table of the embedding die block correspondingly, the adjustable punching die block issimple in structure, a punching debugging die block is provided, when the punching positioning position does not meet the position, the die block can be taken down, the adjusting gasket is ground andrepaired, the punching debugging die block is mounted, scrappage is avoided, and cost is saved.

Owner:江门市新会区益泓不锈钢制品有限公司

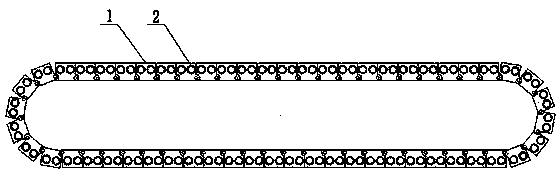

Special chain belt for jujube conveying

InactiveCN103815521ARealize the conveying operationReduce manufacturing costConveyorsFruit stoningEngineeringChain link

The invention relates to a special chain belt for jujube conveying. The chain belt is characterized by comprising no less than three chain links; the chain links are sequentially hinged end to end to form the annular chain belt; the chain links are provided with containing holes for containing jujube. By adopting the conveying chain belt, not only is the manufacturing cost relatively low, but also the processing operation cost can be reduced.

Owner:JIANGSU KAIYI INTELLIGENT SCI & TECH

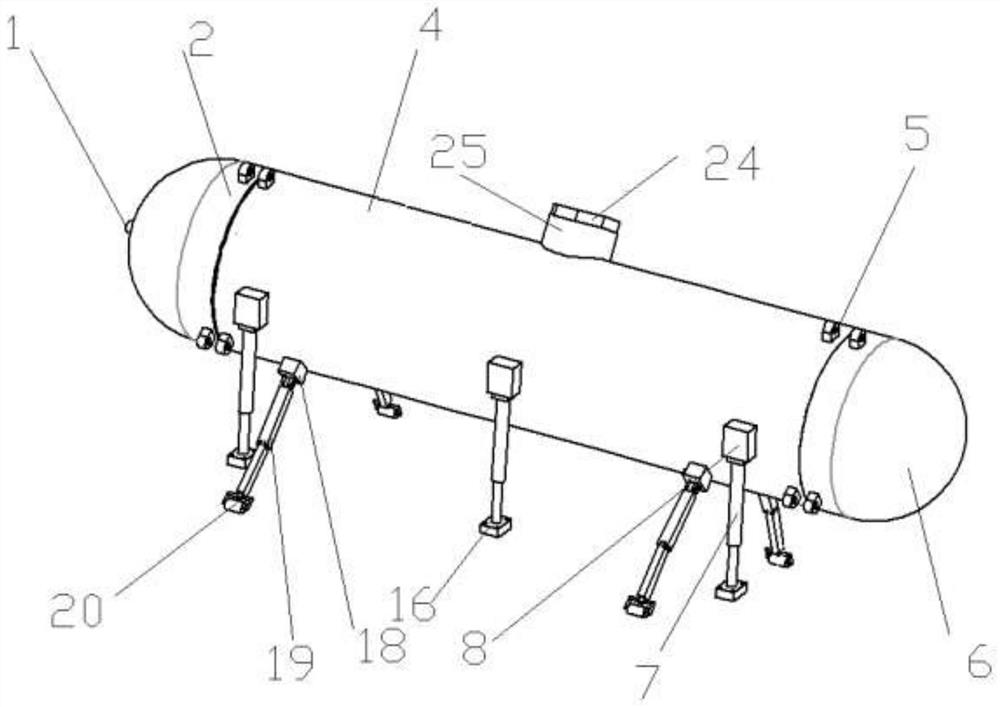

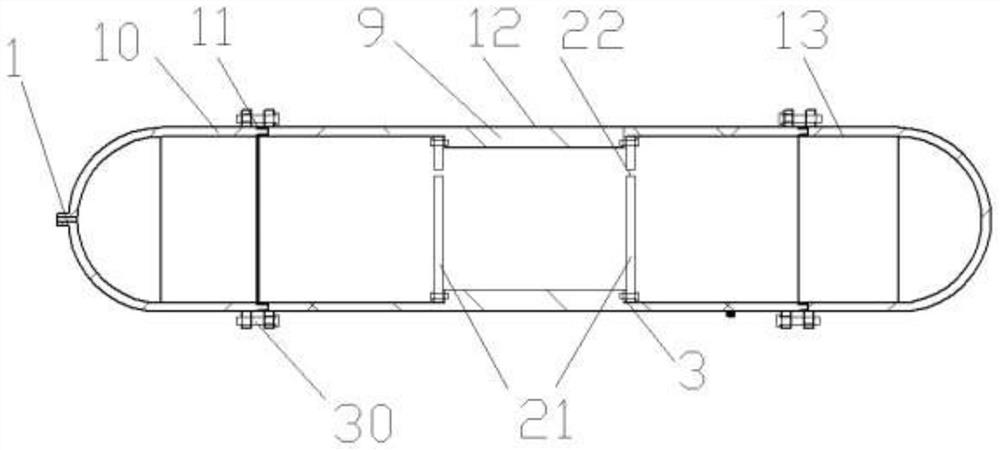

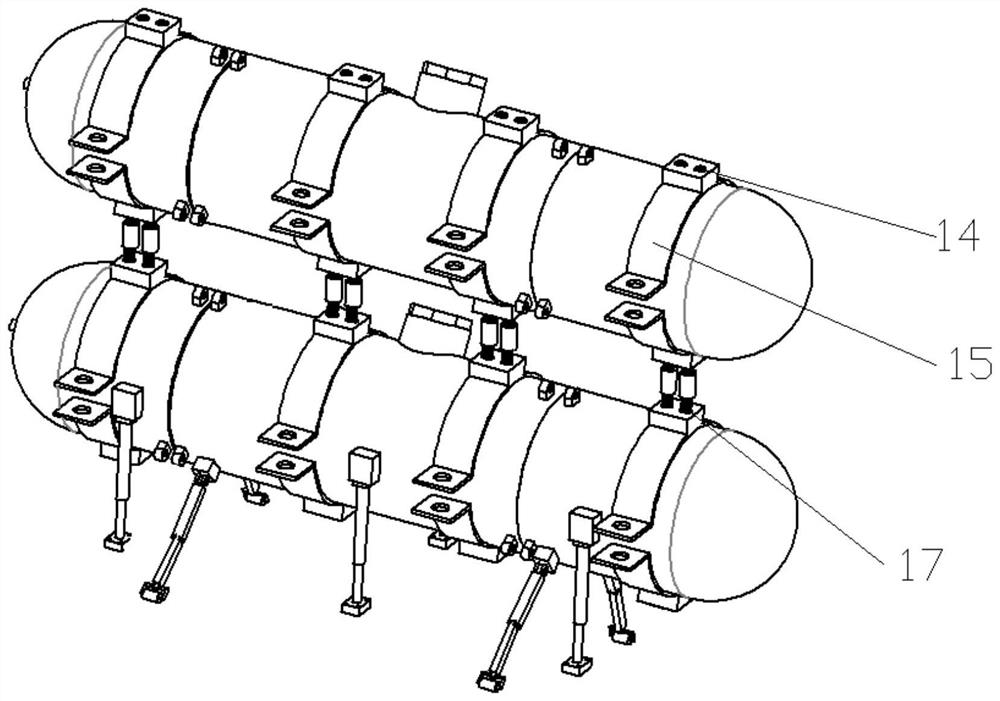

Combined type anti-explosion transportable oil tank based on gradient distribution foamed aluminum

ActiveCN114751109AGuaranteed explosion-proof performanceReduce weightLarge containersOil storageOil tank

The invention discloses a combined type anti-explosion transportable oil tank based on gradient distribution foamed aluminum, and belongs to the technical field of oil storage and transportation equipment, the combined type anti-explosion transportable oil tank comprises an oil tank body, and the oil tank body is of a capsule type structure and comprises an oil tank head with an arc-shaped end face and an oil tank tail. At least one section of oil tank middle part with a cylindrical structure is arranged between the oil tank head part and the oil tank tail part, the number of the oil tank middle parts is increased or decreased according to the requirement of the required oil storage quantity, the oil tank head part and the oil tank tail part are fixed on two sides of the oil tank middle part, and a connecting and pressing mechanism is arranged at the fixed part. A plurality of detachable grounding fixing devices and convenient moving devices are arranged outside the oil tank body and can be connected with other parts independently or in a combined mode, and fixing of the oil tank body is achieved. By improving the structure and the material of the oil tank and arranging a multi-oil-tank stacking structure capable of being combined, the oil tank has the advantages that the storage capacity is changed, and the anti-explosion effect is better.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A production process and device for improving the coding fastness of pp-r pipeline ink

The invention discloses a production technology and a device of improving fastness of an ink jetted code on a PP-R pipeline. According to the technology, the surface of the pipeline is coated with a water-proof bottom layer before code ink jetting of the pipeline; the water-proof bottom layer increases surface free energy of the PP-R pipeline and a bonding force between ink and the pipeline; the jetted code fastness of the ink jetted code on the PP-R pipeline is improved. According to the technology, the surface of the pipeline is coated with the water-proof bottom layer by a circular arc sponge head; the water-proof bottom layer comprises a base material, a waterproofing agent, a curing agent, a surfactant, an adhesive and an environment-friendly plasticizer that are in defined parts; the molecular polarity of the surface of the PP-R pipeline can be improved effectively; the adhesion between the ink and the PP-R pipeline is increased, so that the jetted code fastness is improved; the appearance of the obtained PP-R pipeline is identical with that of the original pipeline; the jetted code fastness is improved by 3 times or above; the technology is simple to operate and easy to achieve, and has no influence on a production speed; the surface of the obtained PP-R pipeline is not damaged; long-term heat resistance pressure of a product is effectively ensured; the product can be used for 50 years or more.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

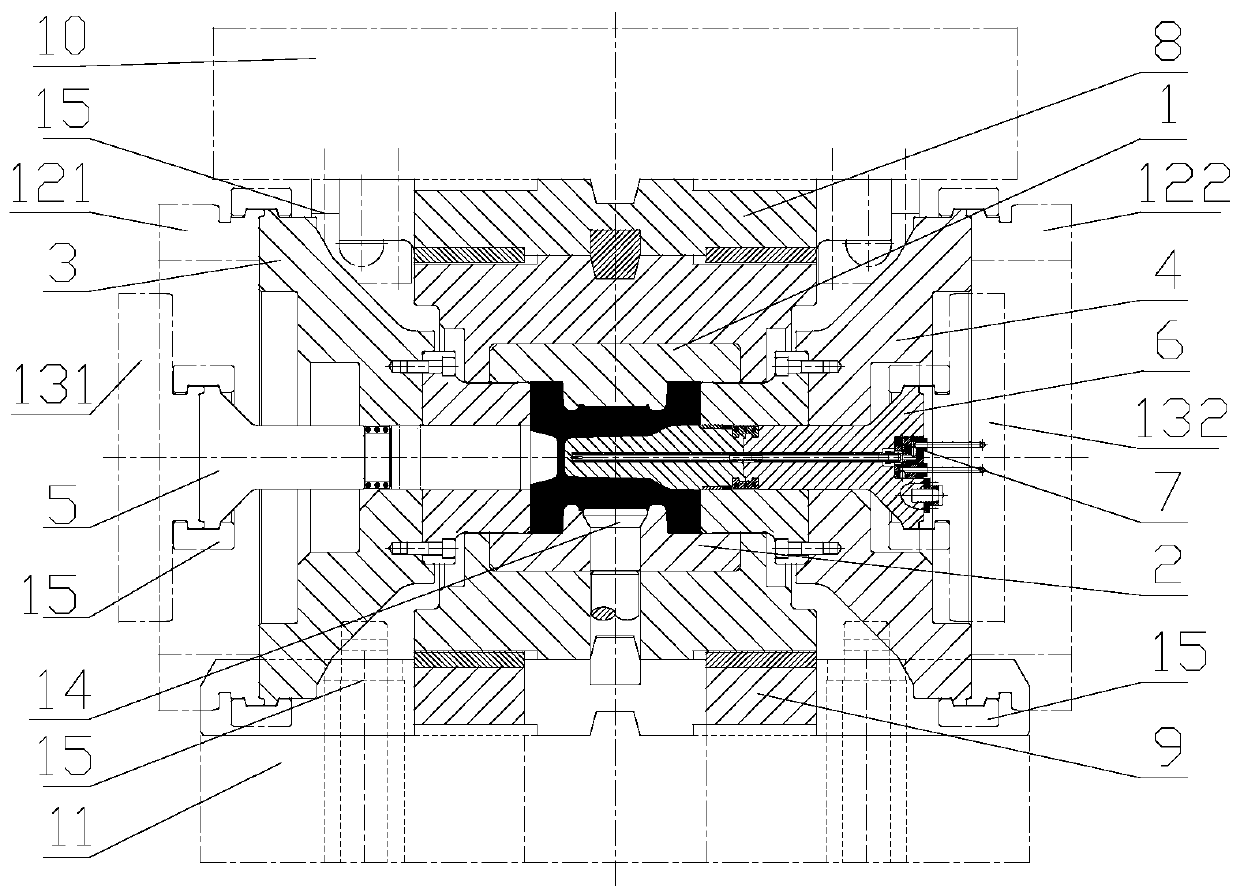

One-time extrusion forming method of horizontal double-acting combined mold of double-flange middle body

The invention discloses a one-time extrusion forming method of a horizontal double-acting combined mold of a double-flange middle body. Meanwhile, the method discloses a horizontal double-acting extrusion combined mold for vertical parting, the vertical upper female die and the vertical lower female die form a circumferential die cavity during die closing, the left horizontal extrusion die and theright horizontal extrusion die form an axial die cavity of the flange together with the vertical upper female die and the vertical lower female die after the die closing, the left horizontal punchingneedle and the right horizontal punching needle are arranged in the left horizontal extruding die and the right horizontal extruding die respectively, a water cooling device is arranged in each penetrating pin, the top head is arranged in the vertical downward concave die, wherein the vertical mold, the horizontal extrusion mold and the perforation tool can move independently. By utilizing the stroke of the extrusion head and the punching needle, the metal can be flexibly controlled to flow reasonably, and the folding defect is avoided, the metal filling of the flange part is full, the product can be formed only by one-time heating and one-time extrusion, the process flow is short, the energy consumption is low, the efficiency is high, and the product size is accurate.

Owner:NANJING DEV ADVANCED MFG

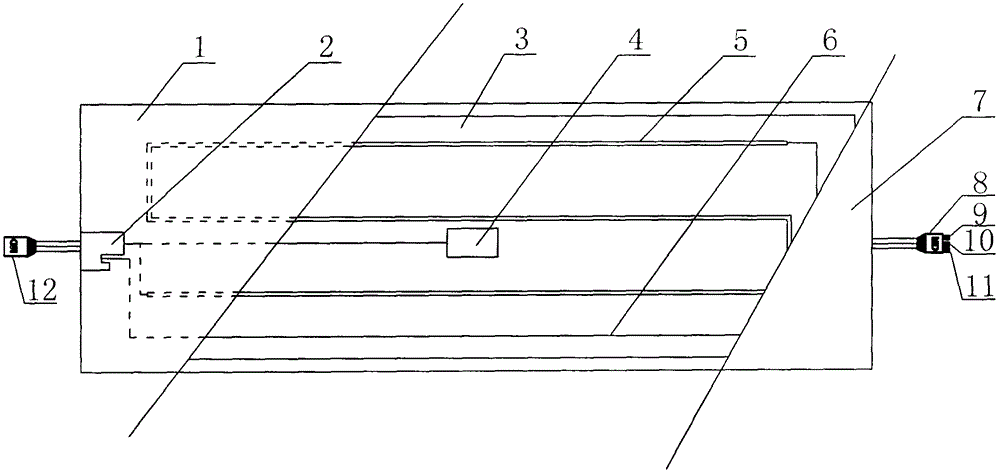

Heating line heater

InactiveCN104566604AEnsure stabilityNo need to scrapLighting and heating apparatusIncorrect coupling preventionSolid woodTectorial membrane

The invention discloses a heating line heater and belongs to the technical field of solid heating wooden floors. The heating line heater comprises a protection film, an aluminum foil, a thermal insulation layer, a heating line, a temperature switch and a heating floor standard power line. The heating line heater is sequentially provided with the protection film, the aluminum foil and the thermal insulation layer from top to bottom; the heating line is arranged on thermosensitive glue on the surface of the aluminum soil; the heating floor standard power line and the temperature switch are arranged between the aluminum soil and the thermal insulation layer; the heating floor standard power line is connected with the temperature switch and the heating line; the heating floor standard power line comprises insulating plugs at two ends, the power line in the middle and a line card which is arranged on the power line. The heating line heater has the advantages that the standard power line which is provided with the heating line is arranged on the back of the wood floor, a branch circuit is formed directly, the problem that the wooden floor machining process is complex is solved, the structure is simple, the utilization is simple, line connection is firm due to female and male insertion joint, error connection and poor contact are thoroughly avoided, and the safety problem is prevented.

Owner:欧邦智能家居(武汉)有限公司

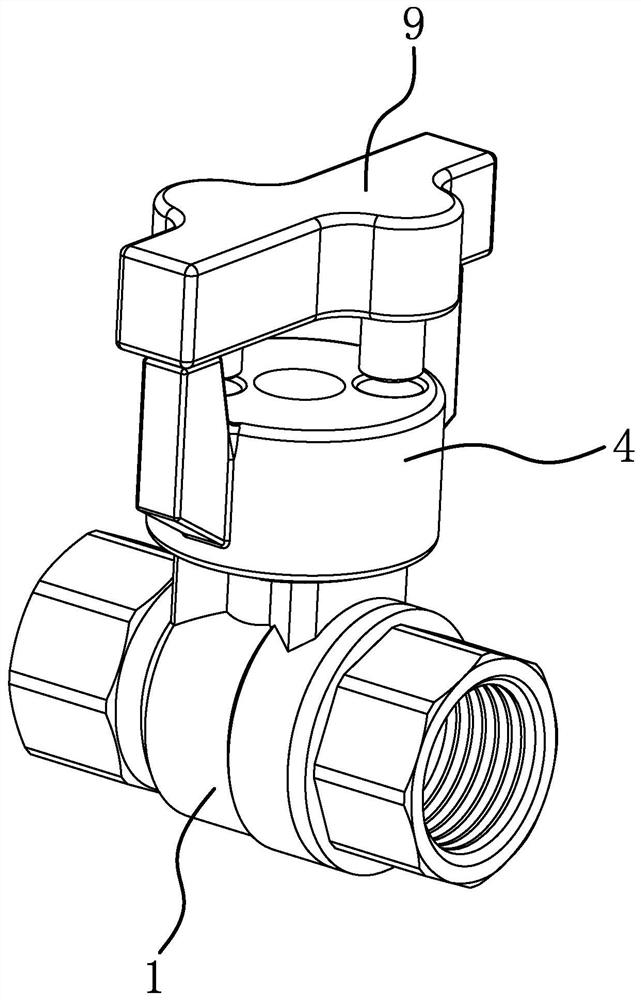

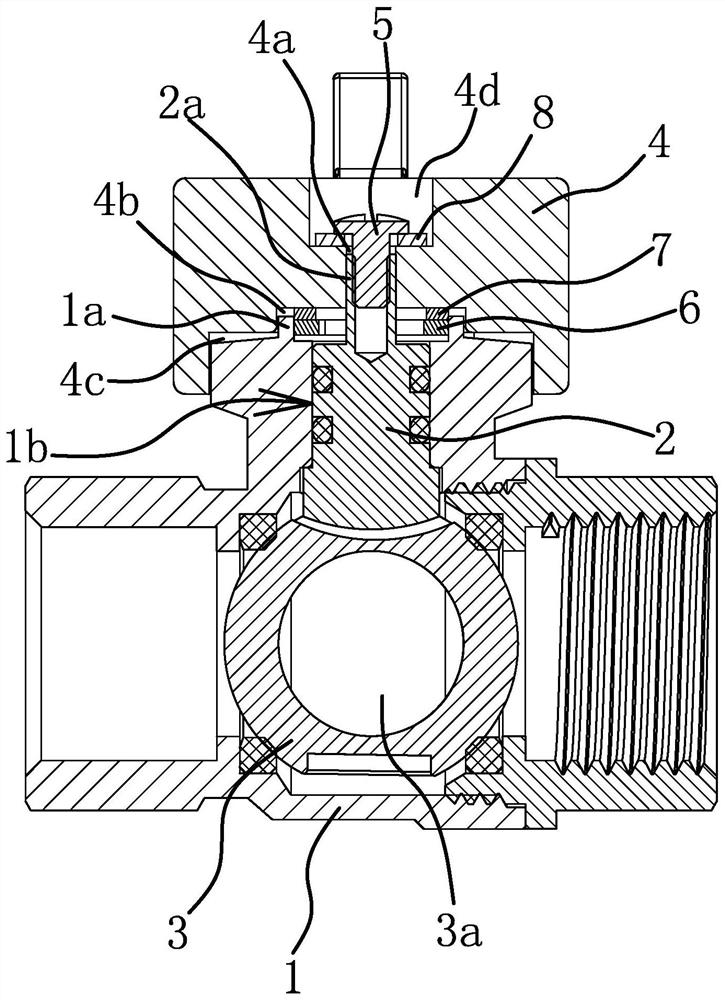

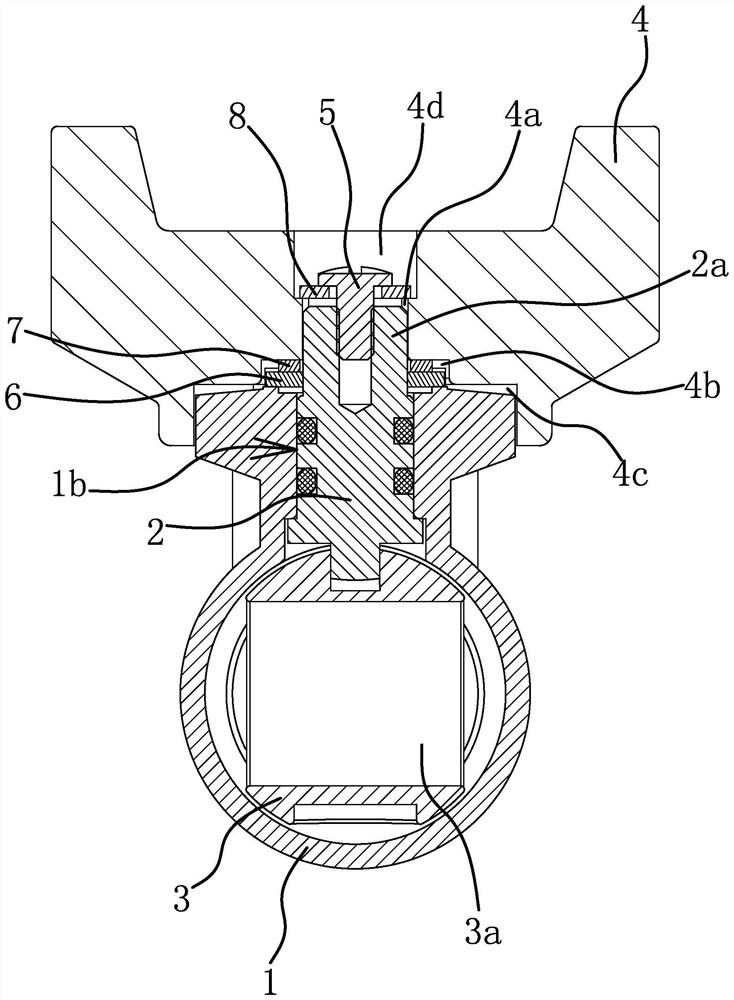

Fuel gas magnetic locking ball valve

PendingCN113566014AEasy to controlSimple processing technologyOperating means/releasing devices for valvesEngineeringFuel gas

The invention provides a fuel gas magnetic locking ball valve, and belongs to the technical field of valves. The problem that the limiting precision is low is solved. The fuel gas magnetic locking ball valve comprises a valve body, a valve rod and a handle connected to the upper end of the valve rod, a connecting part is arranged at the upper end of the valve rod, the handle is provided with a connecting hole matched with the connecting part, the two ends of the connecting hole are through, the top of the connecting part is in threaded connection with a limiting screw preventing the handle from being separated from the connecting part, and the upper end of the valve body is detachably connected with an annular metal limiting piece at the extending position of the valve rod. The metal limiting piece and the valve body are fixed in the circumferential direction, two protruding pieces are arranged on the inner edge of the metal limiting piece, limiting notches are formed between the two adjacent side walls of the two protruding pieces in the circumferential direction respectively, the connecting part penetrates through the metal limiting pieces, and when the valve rod rotates, the connecting part can move along the two limiting notches to abut against the two protruding pieces at the same time, and gaskets are arranged on the metal limiting pieces. The gaskets are elastic and abuts against the lower side of the handle and the metal limiting pieces. The fuel gas magnetic locking ball valve has the advantages of high limiting precision, wide applicability and the like.

Owner:浙江博民机电股份有限公司

Chemical Vapor Deposition Chamber

ActiveCN110016656BImprove uniformityEasy to replaceChemical vapor deposition coatingChemical vapor depositionRadio frequency

The invention relates to a chemical vapor deposition cavity. The chemical vapor deposition cavity comprises a cavity body, a diffusion plate arranged on the upper portion in the cavity, a heating plate arranged on the lower portion in the cavity, and a gas source communicating with the cavity so as to convey process gas to the cavity; the diffusion plate is composed of multiple sub diffusion plates which are evenly distributed in an array manner, the heating plate is composed of multiple corresponding sub heating plates which are evenly distributed in an array manner, the cavity body is provided with multiple corresponding gas and radio frequency conveying positions so as to convey process gas and radio frequency at the corresponding position in the cavity body, and the center of the gas and radio frequency conveying position corresponds to the centers of the corresponding sub diffusion plates and the corresponding sub heating plates. Through the chemical vapor deposition cavity, filmforming uniformity is excellent, the process controllability and stability are improved, key parts of chemical vapor deposition are more convenient to replace and overhaul, after being partly damaged,the key parts of chemical vapor deposition can be replaced, whole scrapping is not needed, and operating cost is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

A production process of high-precision circular weft machine accessories

ActiveCN112404576BNo need to scrapHigh processing error toleranceMetal sawing devicesMachine partsEngineering

The invention discloses a production process of high-precision circular weft machine accessories, comprising the following steps: processing an inner needle cylinder blank and a plurality of outer needle cylinder blanks that can be fixed and covered on the outer side wall of the inner needle cylinder blank; A threaded hole is processed on the inner side wall of the inner cylinder blank, and a connecting hole corresponding to the threaded hole is processed in the inner syringe blank; the outer syringe blank is fixed; the outer wall of the outer syringe blank is processed until the outer wall of the outer syringe blank The needle groove is full; multiple processed outer needle cylinder blanks and inner needle cylinder blanks are fixedly connected together to form a needle cylinder; the needle cylinder processed by this process, when the needle groove on the outer surface of the needle cylinder is damaged during the working process , the outer needle cylinder blank can be replaced according to the damaged area, and the entire needle cylinder does not need to be scrapped, which is more environmentally friendly and reliable; during processing, the entire needle cylinder will not be scrapped because of an error in the processing of a certain needle groove, which will cause the processing failure of the entire needle cylinder, High processing error tolerance.

Owner:漳州市永良针纺机械有限公司

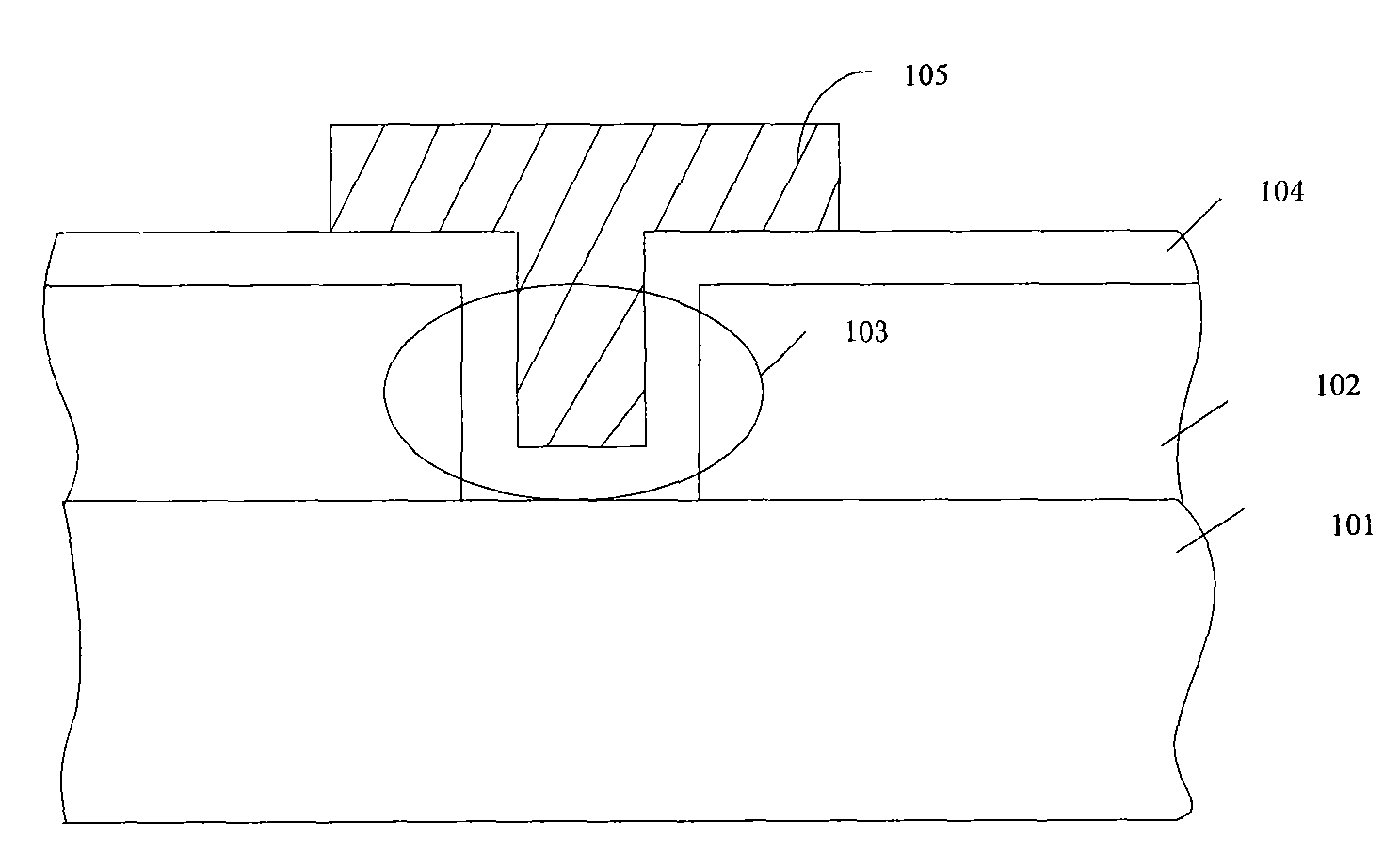

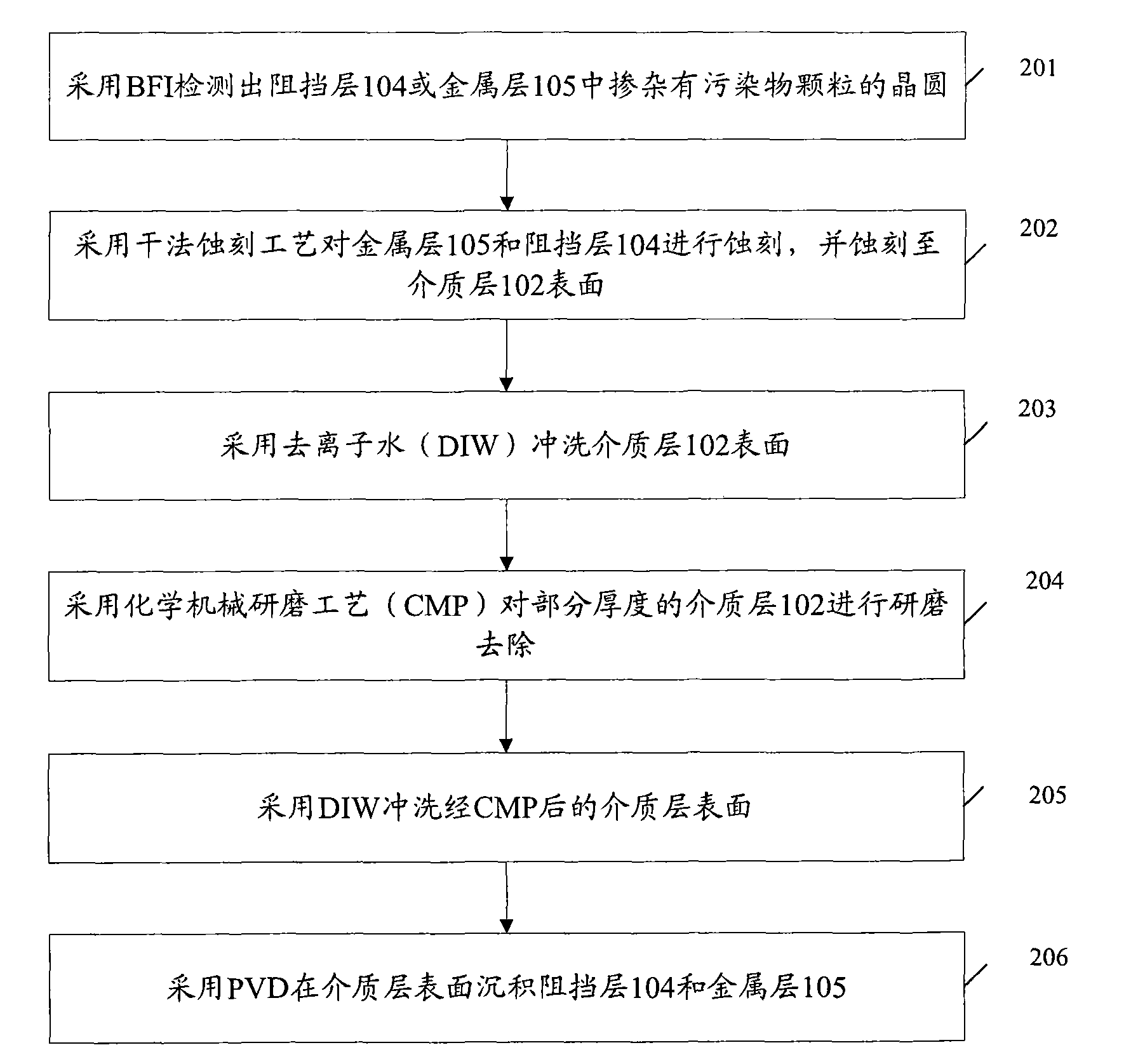

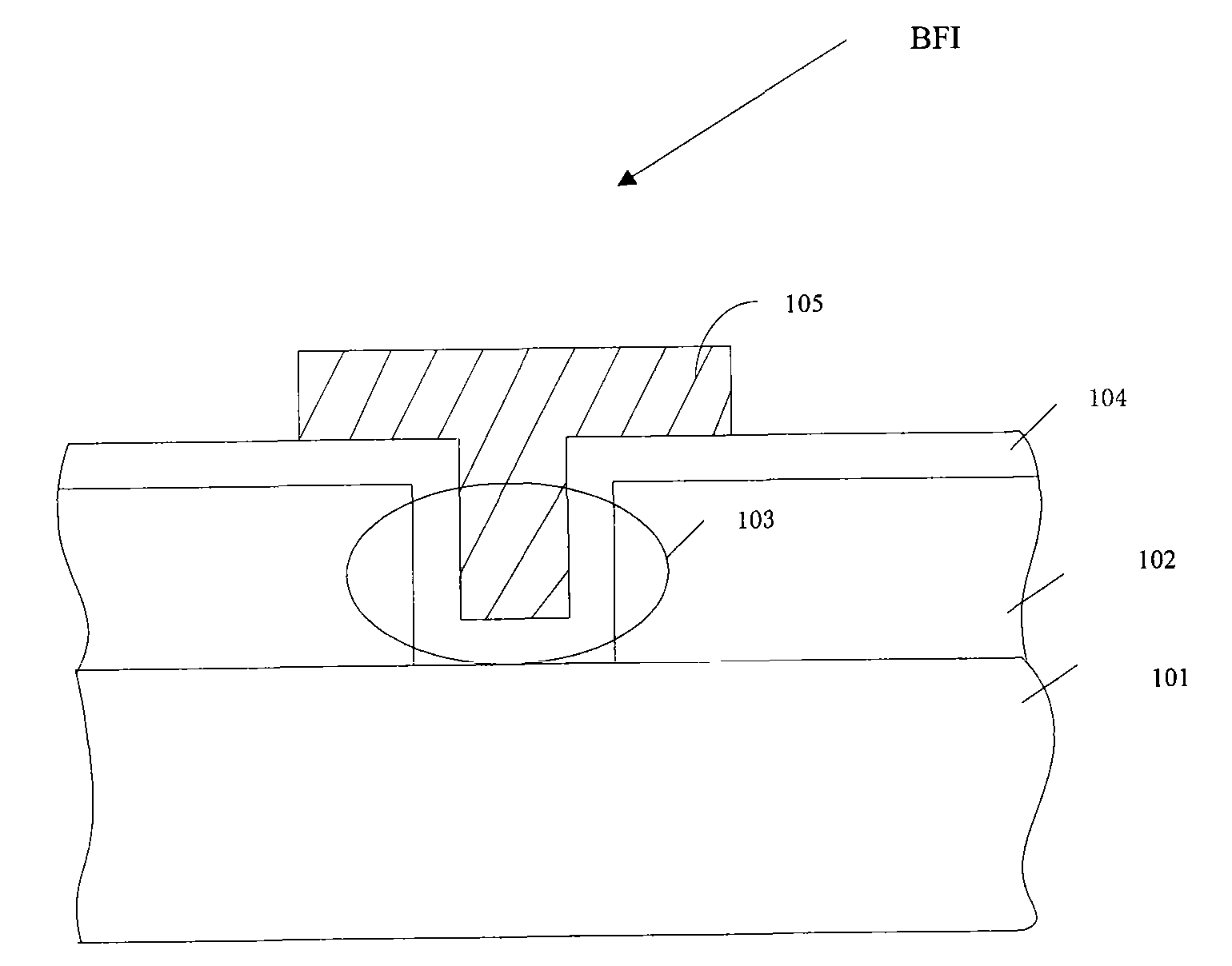

Method for removing pollutant granules in barrier layer and metal layer

InactiveCN101996882BNo need to scrapReduce manufacturing costSemiconductor/solid-state device manufacturingDielectric layerDry etching

The invention discloses a method for removing pollutant granules in a barrier layer and a metal layer, comprising the following steps: etching a metal layer and a barrier layer which are doped with pollutant granules by a dry etching technique and etching to the surface of a dielectric layer; and milling and removing the partial thick dielectric layer by a chemical mechanical polishing process. By employing the method, the production cost of a semiconductor apparatus can be lowered.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

High-temperature continuous thermal treatment furnace for saw blades

ActiveCN102134635BImprove efficiencyHeating up fastFurnace typesHeat treatment furnacesVertical planeEaves

The invention discloses a high-temperature continuous thermal treatment furnace for saw blades, which comprises a shell, an insulating layer, a thermocouple and a heating module in the insulating layer, wherein the heating module comprises a heating chamber arranged along the advancing direction of a saw blade, a heating rod vertically passing through the insulating layer and extending into the heating chamber, a muffle pipe in the heating chamber, and a ceramic guide supported by a bracket in the muffle pipe; the heating chamber consists of a plurality of repeating units which are spliced inturn; each repeating unit is enclosed by a base, side walls symmetrically arranged on two sides, and a top cover vertically passing through the insulating layer; and each side wall comprises a lateral standing part and a flat eaves part arranged on the inner side of the top end of the lateral standing part, wherein the inner side face at the bottom end of the lateral standing part is in sealed fit with the base; the inner side face of the flat eaves part is a vertical plane and is in sealed fit with the side wall of the top cover; two ends of the inner side of the lateral standing part are provided with baffles used for supporting the top cover; and the flat eaves part between the two baffles is provided with a through hole for the heating rod to pass through. The thermal treatment furnace heats the saw blades in the muffle pipe through the heating rod, the temperature rise is quick and the efficiency is high.

Owner:金湖汇达智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com