Insertion sheet spliced type splash-proof grating of high-order water-saving cooling tower

A high-level water collection and cooling tower technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problem of water ineffective recovery and diversion, increased use costs, and difficult production. problems, to achieve the effect of facilitating the organization of large-scale production, reducing transportation costs, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

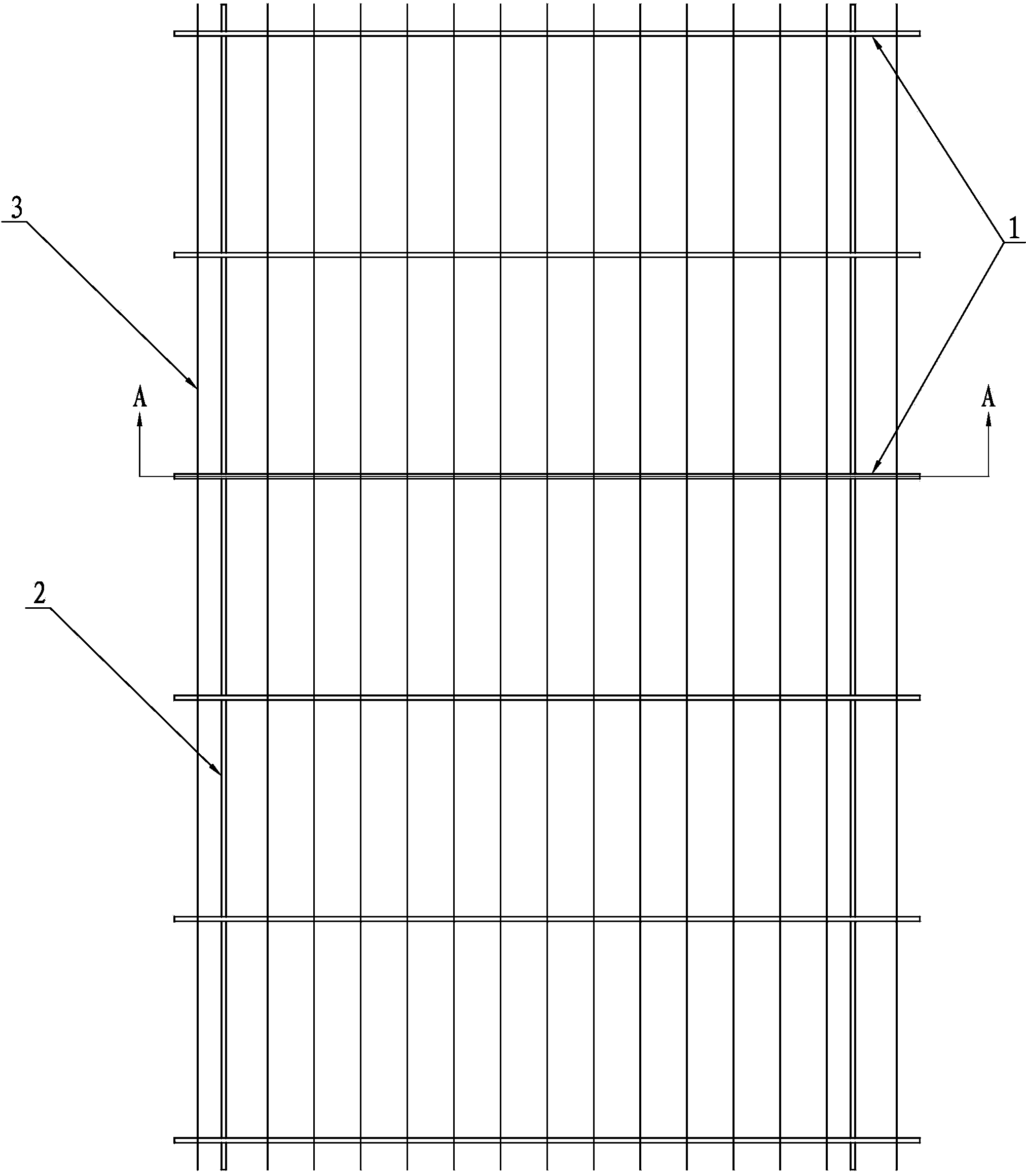

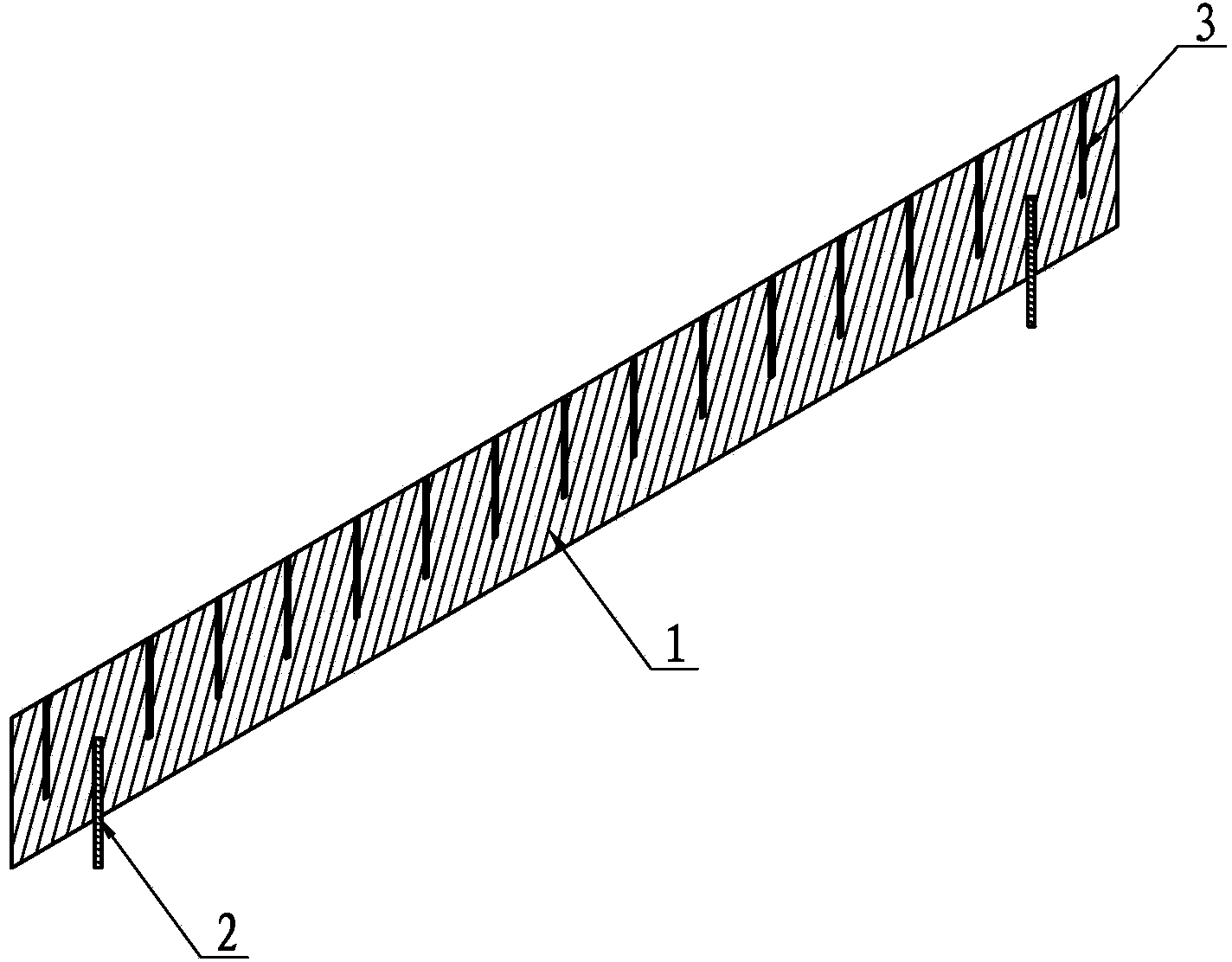

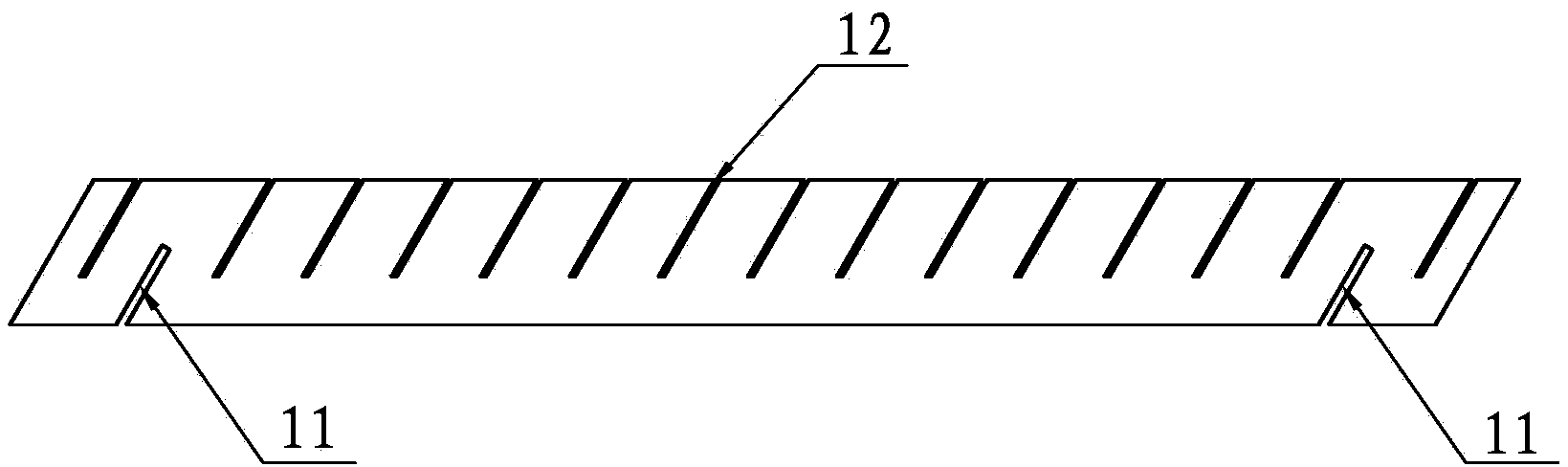

[0022] Embodiment 1: A high-level water collection cooling tower insert-assembled splash-proof grille, such as Figure 1~3 As shown: it is composed of six horizontal fixing plates 1, two vertical fixing plates 2 and fifteen longitudinal inserts 3, and the two ends of the horizontal fixing plate 1 are provided with insertion grooves 11 with openings downward, and the horizontal fixing plates 1 is provided with fifteen slots 12 with upward openings at equal intervals, and six occlusal grooves 21 with upward openings are arranged at equal intervals on the longitudinal fixing plate 2, and the two longitudinal fixing plates 2 are arranged in parallel and symmetrically. The fixing plate 1 is respectively inserted into the corresponding engaging grooves 21 on the longitudinal fixing plate 2 through the two insertion slots 11 on it, so that the horizontal fixing plate 1 and the longitudinal fixing plate 2 are vertically engaged with each other, and all the horizontal fixing plates 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com