Adjustable stripping tower for soybean mixing oil precipitation

An adjustable, stripping tower technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of unable to replace the stripping device, not found, etc., to achieve the effect of increasing service life, improving quality, and low residual solvent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

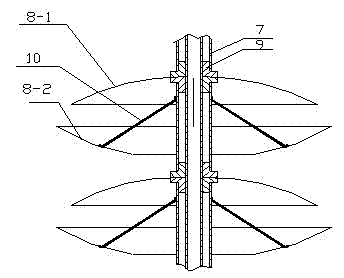

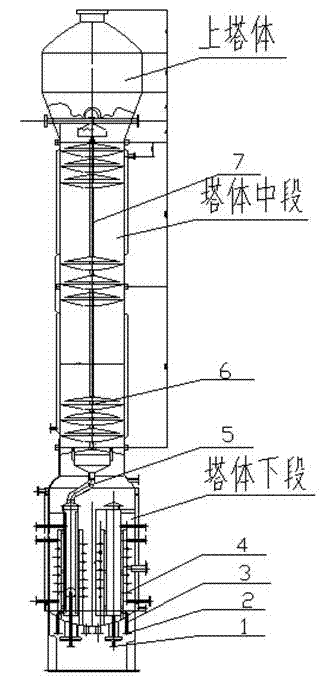

[0008] Specific implementation mode one: as figure 1 As shown, the adjustable stripper of this embodiment includes two sets of mammoth pumps 1, two sets of central oil guide pipes 2, two sets of serpentine pipes 3, separated by partitions 4, manholes 5 are provided on the tank body, and the tower The lower end of the body is connected with the central shaft 6 of the tower body by the oil pipe. The outer side of the central shaft 6 of the tower body is covered with a casing 7. The casing 7 is divided into multiple sections, and a disc 8 is inserted in the middle. Each set of discs is divided into an upper disc 8-1. And following disc 8-2, be enclosed within on the central shaft 6, be detachable type, last disc 8-1 is fixed by central sleeve shaft 9, and following disc 8-2 is fixed by tie bar 10. The central shaft 6 is covered with multiple sets of discs, which are evenly arranged on the central shaft 6 .

specific Embodiment approach 2

[0009] Specific implementation mode two: adjustable working principle components such as figure 2 Shown: According to the size of the output, the size and spacing of the discs can be adjusted to achieve the purpose of producing different outputs. At the same time, when the disc has a lot of fouling and needs to be cleaned, remove the sleeve along the central shaft, open the central sleeve shaft, and pull out the upper disc from the central shaft. The lower sleeve of the upper disc and the lower disc are connected by tension Connect, remove for cleaning.

specific Embodiment approach 3

[0010] Embodiment 3: An adjustable stripping tower for soybean mixed oil desolventization, which is characterized in that a heating interlayer is added to the central oil guide pipe and the lower tower body to ensure the heating temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com