A production process of high-precision circular weft machine accessories

A production process and technology of circular weft machine, which is applied in the field of high-precision circular weft machine parts production process, can solve the problems of many looping systems, scrapped needle cylinders, unenvironmental protection, etc., and achieves the effect of high processing error tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

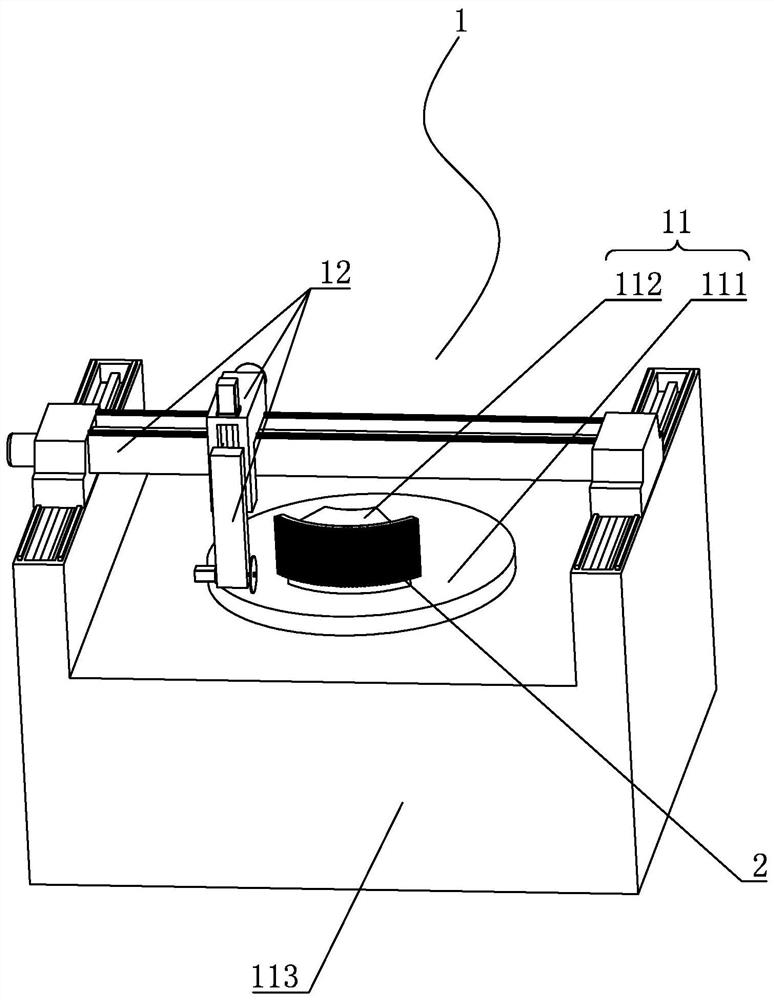

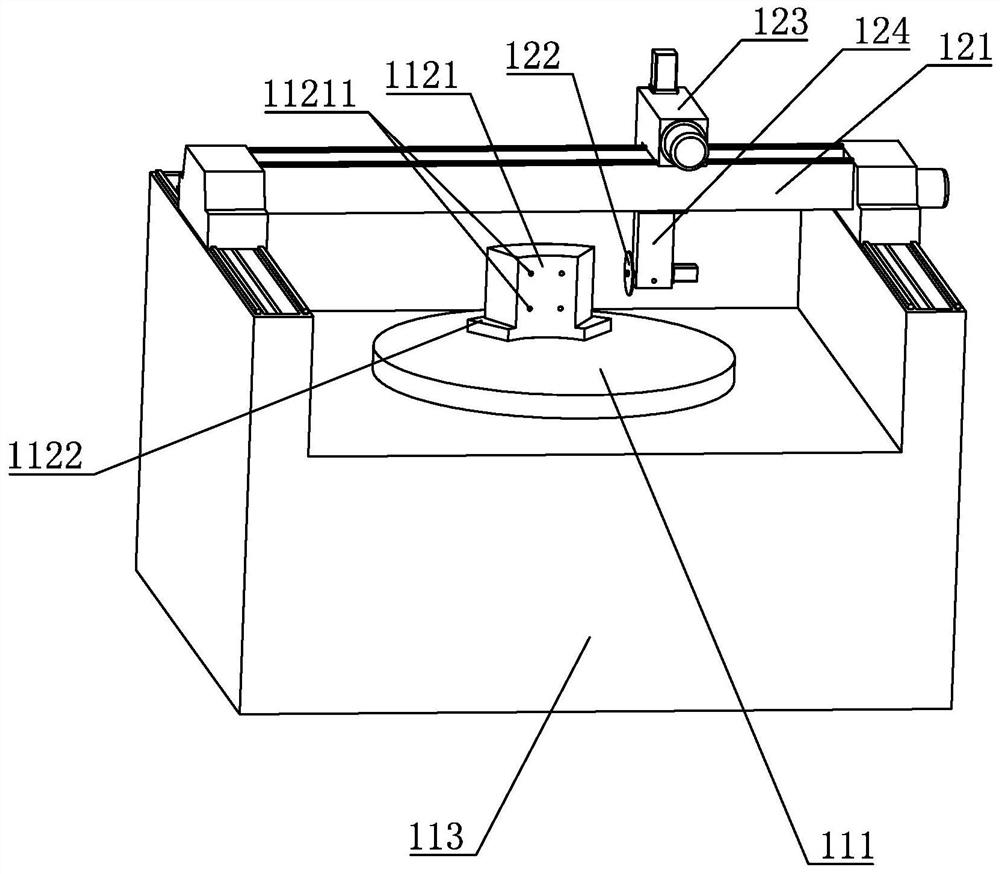

[0041] like Figure 1 to Figure 6 As shown, it is a production process for high-precision circular weft machine accessories involved in the present invention, comprising the following steps:

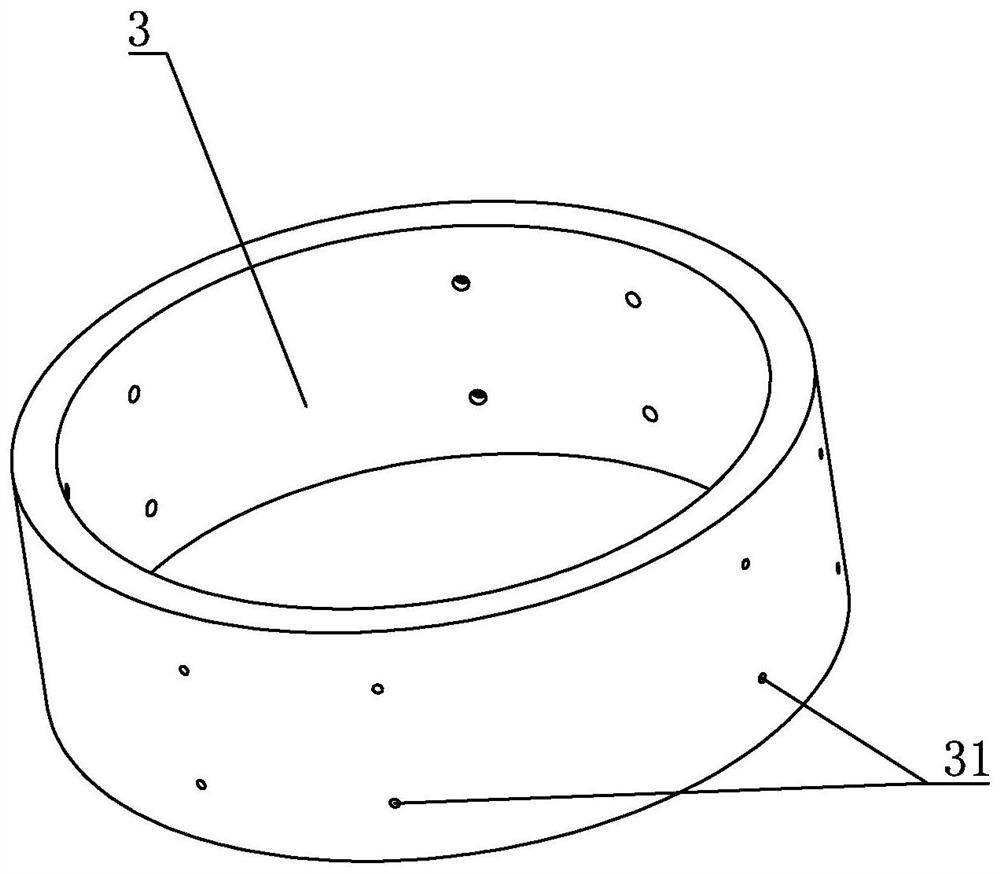

[0042] (1) processing the inner needle cylinder blank 3 and a plurality of outer needle cylinder blanks 2 that can be fixed and covered on the outer side wall of the inner needle cylinder blank 3;

[0043] (2) A threaded hole is machined on the inner side wall of the outer needle barrel blank 2, and a connecting hole 31 corresponding to the threaded hole is machined into the inner needle barrel blank 3; the threaded connection is more reliable; the connecting hole 31 includes a connecting part and a countersunk head The diameter of the countersunk head is larger than the diameter of the connecting part and the counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com