Heating line heater

A heating wire and heater technology, which is used in household heating, heating methods, electric heating systems, etc., can solve the problems of inability to use ordinary wood floor heating, waste of resources, waste boards, etc., to prevent misconnection and poor contact, Eliminate safety problems and secure wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

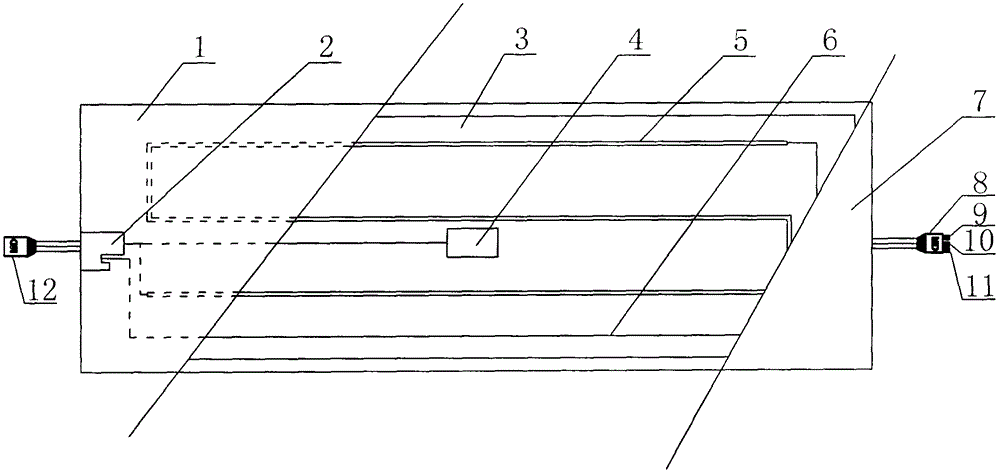

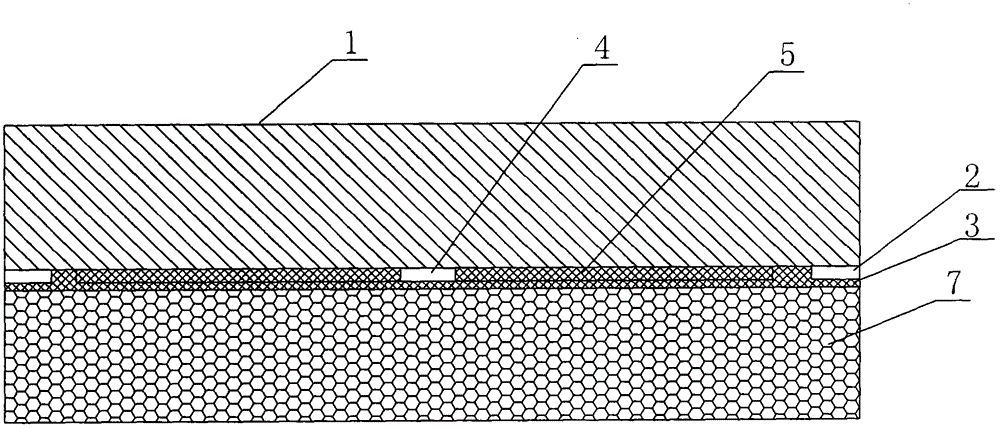

[0015] Example 1, such as figure 1 , 2 As shown, a heating wire heater includes a protective film 1, an aluminum foil 3, an insulation layer 7, a heating wire 5, a temperature switch 4 and a standard power wire for heating floors, and the heating wire 5 heater is arranged in sequence from top to bottom. There is a protective film 1, an aluminum foil 3 and an insulation layer 7; the heating wire 5 is arranged on the heat-sensitive adhesive on the surface of the aluminum foil 3, and a heating floor standard power line and a temperature switch 4 are arranged between the aluminum foil 3 and the insulation layer 7; The heating floor standard power cord is connected to the temperature switch 4 and the heating wire 5; the heating floor standard power cord includes insulating plugs at both ends, a power cord 6 in the middle, and a line card 2 located on the power cord 6; The left end of the heating floor standard power cord is a left insulating plug 12, the right end is a right insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com