Chemical Vapor Deposition Chamber

A chemical vapor deposition and chamber technology, applied in the field of chemical vapor deposition chambers, can solve problems such as difficulty in controlling film formation uniformity, and achieve the effects of excellent film formation uniformity, lower operating costs, and convenient replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

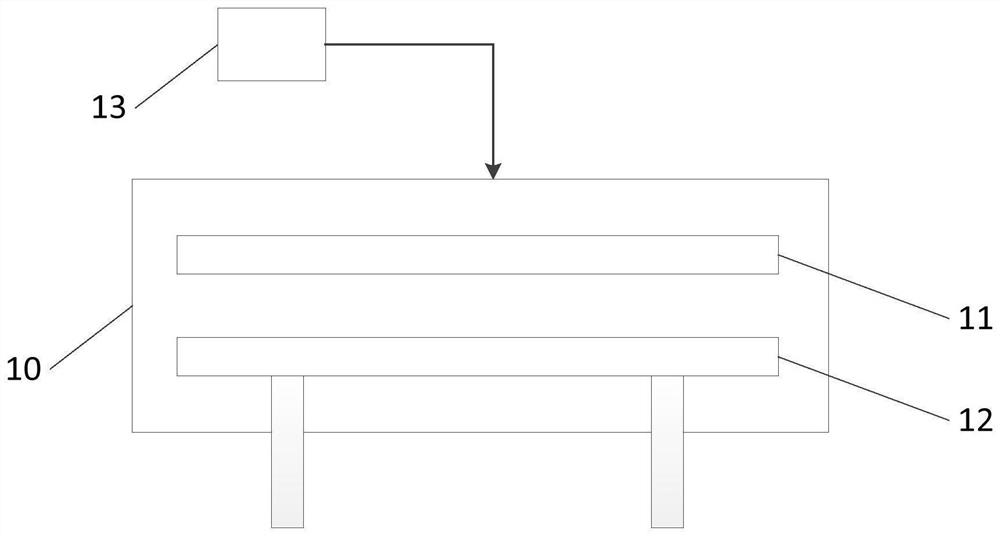

[0027] see Figure 5 , which is a schematic cross-sectional structure diagram of a preferred embodiment of the chemical vapor deposition chamber of the present invention, the chemical vapor deposition chamber of the present invention mainly includes a chamber 20, a diffusion plate 21 arranged on the upper part of the chamber 20, and the diffusion plate 21 mainly Used to make the process gas diffuse evenly, the heating plate 22 installed in the lower part of the chamber 20, the heating plate 22 is mainly used to carry the substrate during the film forming process, and communicate with the chamber 20 to deliver the gas source of the process gas to the chamber 20 23 , the top of the chamber 20 is provided with a gas delivery port to allow the process gas to enter the chamber 20 .

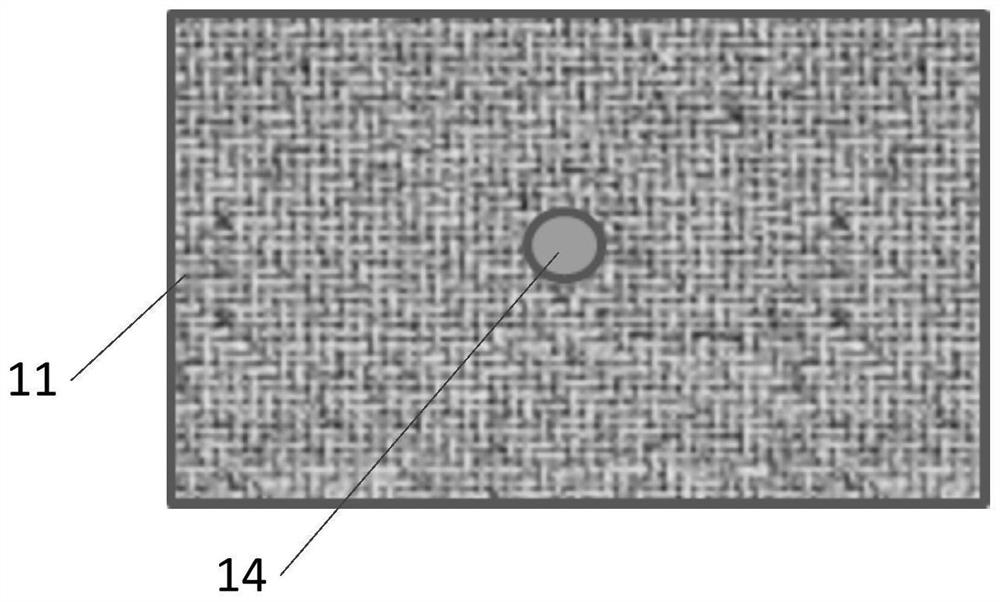

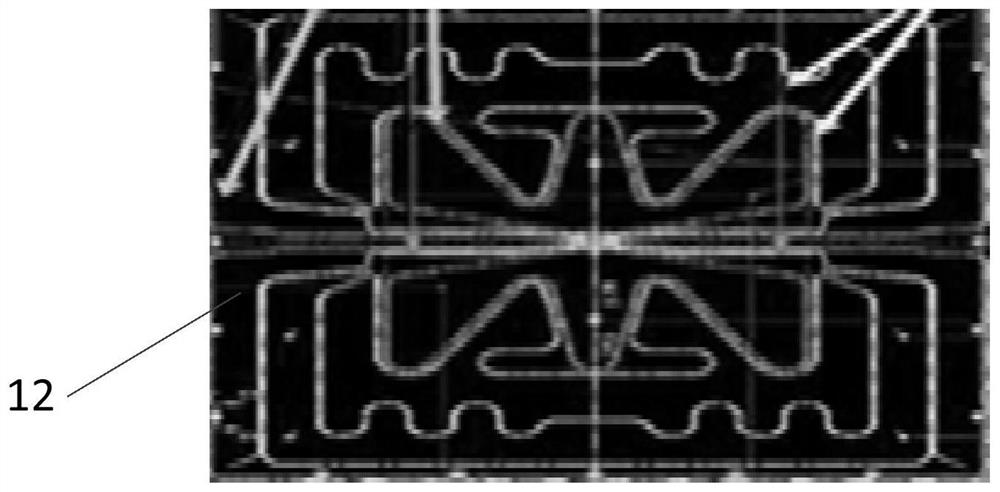

[0028] combine Figure 6 and Figure 7 , Figure 6 for Figure 5 Schematic top view of the diffuser plate and gas and RF delivery locations of the shown chemical vapor deposition chamber, Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com