High-temperature continuous thermal treatment furnace for saw blades

A heat treatment furnace and saw blade technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as inaccurate temperature detection, poor heat preservation performance, and long heating time, and achieve accurate measurement, convenient replacement, and improved heat preservation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

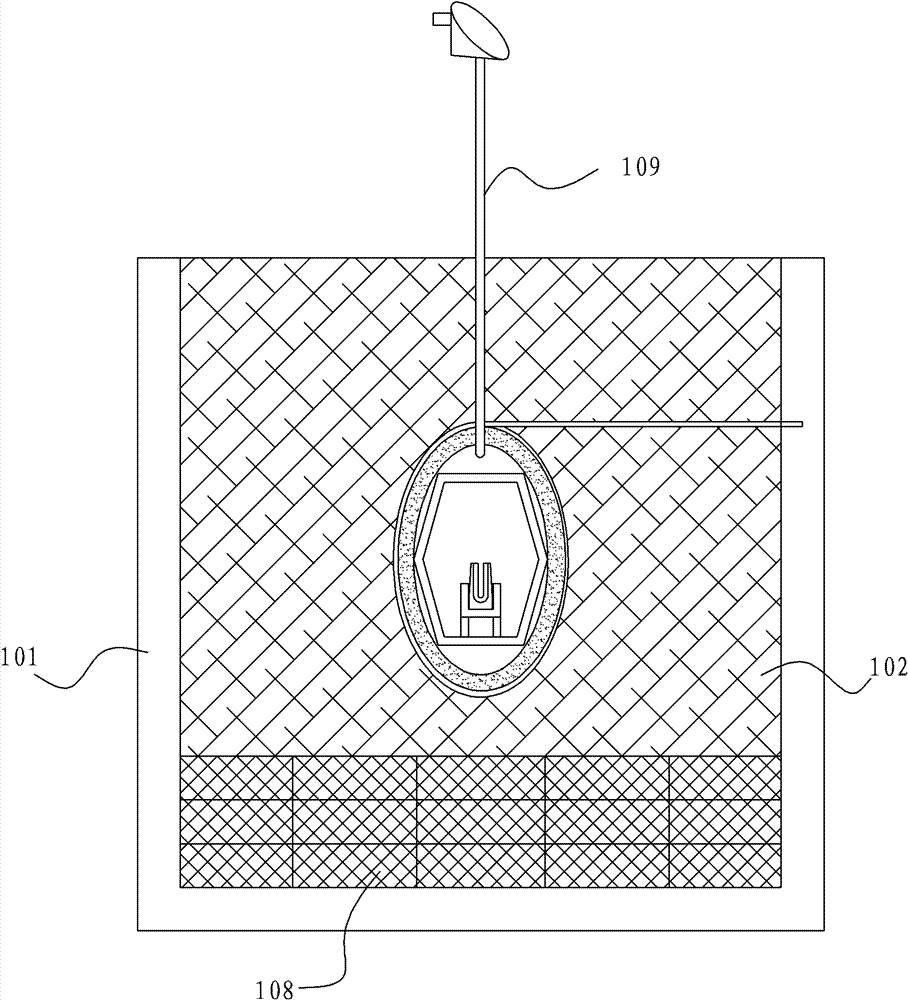

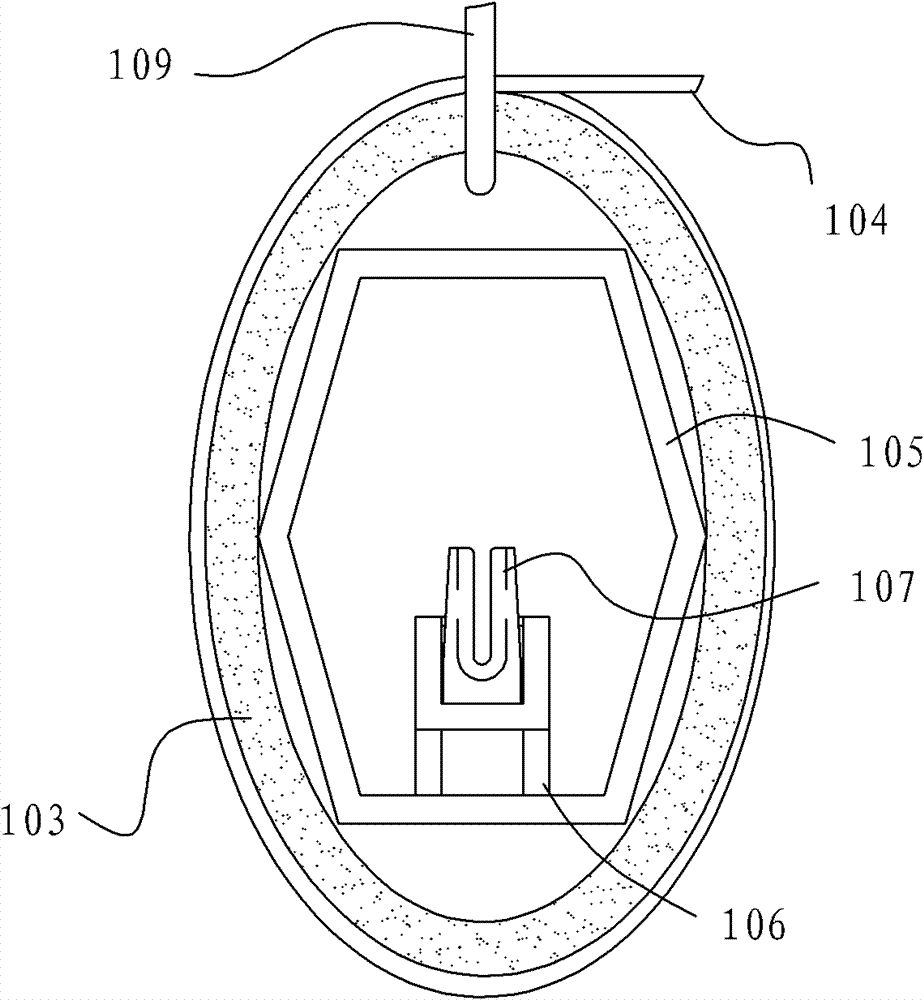

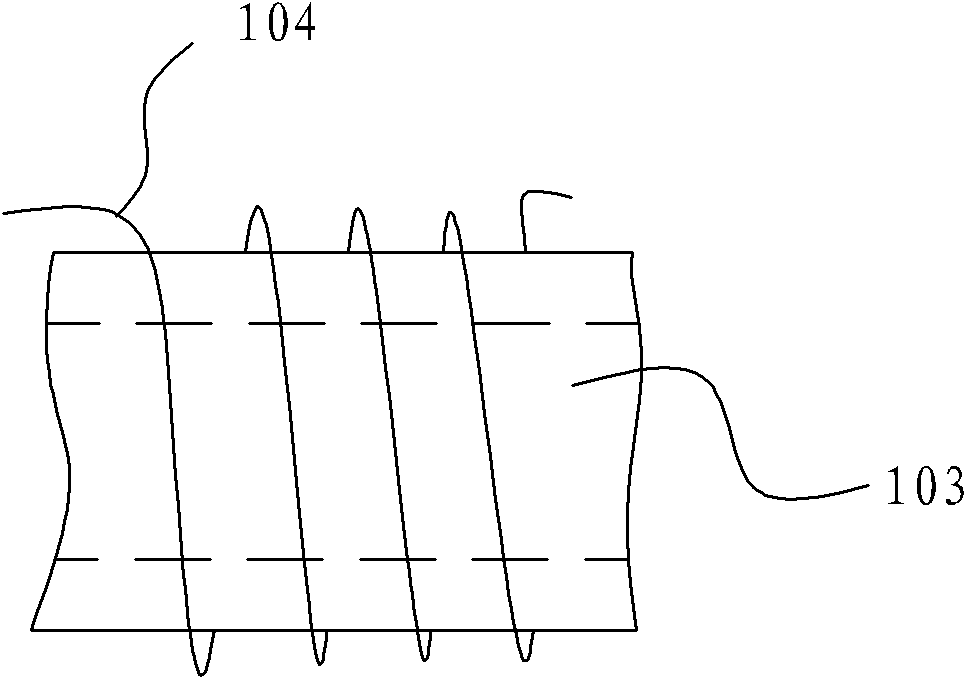

[0026] As shown in the figure, a high-temperature continuous heat treatment furnace for saw blades includes a shell 2, a hollow interlayer 2 is provided on the side wall of the shell 2, and an insulating layer 3 is provided around the inner cavity of the shell 2, and the insulating layer on each side is composed of several insulating plates ( Ceramic fiber machine-made boards) are stacked, the longitudinal section of the inner cavity of the shell is square, and the ends of the insulation boards on the adjacent sides are staggered, which not only has good thermal insulation performance, but also does not shrink and deform.

[0027] The center of the insulation layer 3 is a heating module. The heating module includes a heating chamber 4, a muffle tube 5 in the heating chamber, and two sets of ceramic guides 7 supported by brackets 6 in the muffle tube 5. The ceramic guide 7 is provided with an axial guide. For the ceramic part of the guide groove, when installing, the front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com