A production process and device for improving the coding fastness of pp-r pipeline ink

A PP-R, production process technology, applied in coating and other directions, can solve the problems of poor laser coding clarity and aesthetics, disappearance of coding content, easy falling off of coding, etc. The code fastness is improved to ensure the effect of long-term heat resistance and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

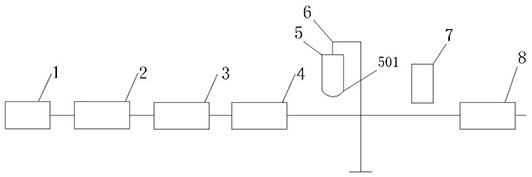

[0028] 7 kg of ethyl acetate as the base material of the waterproof bottom layer, 0.6 kg of sodium methyl siliconate as a waterproofing agent, 0.3 kg of m-phenylenediamine as a curing agent, 0.3 kg of fatty acid glyceride as a surfactant, 1 kg of polyacrylic acid as an adhesive, and 1 kg of environmentally friendly plasticizers Put 0.1 kg of agent DOTP into a 30L mixing bucket and stir for 5 minutes at a speed of 600r / min, pour it into the bucket 5 of the waterproof bottom device, screw on the lid with the arc-shaped sponge head 501, and place it upside down on the adjustable bracket 6 According to the size of the pipe specification, adjust the height of the adjustable bracket 6 on the waterproof bottom to ensure that the arc-shaped sponge head 501 is just in contact with the pipe.

[0029] Extrude the PP-R pipe, the temperature of the barrel and the temperature of the extrusion die 1 are not significantly different from those of ordinary PP-R. The fourth stage is 190°C. Then...

Embodiment 2

[0031] 4.2 kg of ethyl acetate as the base material of the waterproof bottom layer, 0.3 kg of sodium methyl siliconate as a waterproofing agent, 0.1 kg of m-phenylenediamine as a curing agent, 0.25 kg of fatty acid glyceride as a surfactant, 0.8 kg of polyacrylic acid as an adhesive, and 0.8 kg of environmentally friendly plasticizers Put 0.045kg of agent DOTP into a 30L mixing bucket and stir at a speed of 600r / min for 5min, pour it into the bucket 5 of the waterproof bottom device, screw on the lid with the arc-shaped sponge head 501, and place it upside down on the adjustable bracket 6 On, adjust the height of the adjustable bracket 6 of the waterproof bottom layer according to the size of the pipeline to ensure that the arc-shaped sponge head 501 is just in contact with the pipeline.

[0032] Extrude the PP-R pipe, the temperature of the barrel and the temperature of the extrusion die 1 are not significantly different from those of ordinary PP-R. The fourth stage is 190°C....

Embodiment 3

[0034] Use 7 kg of ethyl acetate as the base material of the waterproof bottom layer, 0.8 kg of sodium methyl siliconate as a waterproofing agent, 0.5 kg of m-phenylenediamine as a curing agent, 0.62 kg of fatty acid glyceride as a surfactant, 1.5 kg of polyacrylic acid as an adhesive, and 1.5 kg of environmentally friendly plasticizers. Put 0.2 kg of agent DOTP into a 30L mixing bucket and stir for 5 minutes at a speed of 600r / min, pour it into the bucket 5 of the waterproof bottom device, screw on the lid with the arc-shaped sponge head 501, and place it upside down on the adjustable bracket 6 According to the size of the pipe specification, adjust the height of the adjustable bracket 6 on the waterproof bottom to ensure that the arc-shaped sponge head 501 is just in contact with the pipe.

[0035] When the PP-R pipe is extruded, the barrel temperature and die head temperature are not significantly different from those of ordinary PP-R. The barrel temperatures are: 185°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com